RFID factory inventory management solution

[ad_1]

Project Background

Excellent factory inventory management ability is an important indicator of a company’s executive ability assessment. Factory inventory management is subject to the influence of manpower, cost, and staff quality, and the following problems have always existed.

Question one:

Always use barcode label scanning, barcode label scanning one-to-one, scanning efficiency needs to be improved.

Question two:

Bar code labels are prone to missed reading and scanning of missing pieces.

Question three:

The label is blurred and damaged seriously, and the problem of label persistence needs to be solved urgently.

Question four:

The label cannot be reused.

Question five:

The safety performance is not high, and the anti-theft performance is lacking.

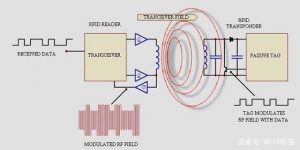

System schematic diagram

3. System structure

RFID factory inventory management is mainly composed of electronic tags pasted on warehouse goods, access control antennas and readers, and inventory management software.

(Among them, the access control antenna mainly plays a role of anti-theft, when the warehouse goods with electronic tags pass the access control, the alarm will automatically alarm)

First of all, it is necessary to give each goods in the warehouse an “identity”, that is, to attach an electronic label that records his personal information. For centralized management.

Secondly, the identities of all items have been entered into the system, and a file (data collection) is formed in the system. A handheld reader can be used at a fixed time to verify the identity of “everyone” in the factory.

Ensure the accuracy, efficiency and timeliness of factory inventory management.

4. System performance

Advantage 1:

Systematization and automation of factory inventory entry and exit.

Advantage 2:

Read tags in batches and realize inventory counting in seconds.

Advantage three:

Flat browsing, reducing space barriers (RFID penetration is strong)

Advantage four:

RFID electronic tags can be repeatedly erased and written 100,000 times, and the data is stored for 10 years. Special tags are not afraid of acid, alkali, high temperature, or even corrosion.

Advantage five:

Various shapes, support customization, suitable for all kinds of factory goods.

[ad_2]