Platform scale intelligent unattended weighing system technical solution

[ad_1]

1. What is an unattended intelligent weighing system?

The unattended intelligent weighing system makes the original rough and complicated weighing management work very efficient, simple and convenient, and at the same time completely eliminates all kinds of weighing cheating. The system has been seamlessly integrated with the coal transportation and marketing management system and the ERP enterprise management software system. It can not only complete the weighing and anti-cheating function of material receiving and dispatching, but also realize the production, contract management, port management, freight settlement, and financial statistics. , Invoicing, assets, equipment, laboratory and other integrated management, this system improves management level, prevents weighing cheating, plugs management loopholes, reduces consumption, effectively controls costs, regulates production order, improves work efficiency, and improves economic benefits , Played a very positive role.

(1) The role of unattended intelligent weighing system

In the entire weighing process, automatic and reliable measurement data collection, automatic discrimination, automatic command, automatic processing, and automatic control are achieved, which minimizes the drawbacks and work intensity caused by manual operation, and improves the informatization and automation of the system. degree.

1. For the management department, you can understand the current production and logistics status through the summary report in the system;

2. For the financial settlement department, you can get clear and accurate settlement reports;

3. For the warehouse management department, you can learn about your own receipt and delivery of goods.

These report data can be consulted at any time, so it also strengthens the consistency of management, shortens the response time of decision makers to production, improves management efficiency, reduces operating costs, and promotes enterprise information management.

(2) Unattended intelligent weighing system function

According to different customer requirements and actual measurement conditions, tailor-made for customers, and develop an unmanned truck scale intelligent weighing system that meets the customer’s actual conditions and requirements according to the customer’s specific work process.

(1) Weighing data acquisition module:

The unattended intelligent weighing system adopts an open interface protocol design to meet various domestic and foreign truck scale instruments in use in domestic factories, mines, customs, ports, etc.

(2) Realize two-way over-balance intelligent weighing:

This system meets the requirements of two-way over-balance weighing of truck scales, and can realize unattended intelligent weighing in both directions.

(3) Long-distance Bluetooth automatic recognition subsystem-electronic license plate anti-cheating module

The recognition distance of the electronic license plate is more than 15 meters, and it can automatically identify the license plate number, model, owner, transportation unit and other information of the overweight vehicle, and judge the legality of the overweight. If it is an authorized legal vehicle, it will be weighed smoothly. If it is an illegal vehicle, overweight weighing is not allowed.

(4) Anti-tare cheating module:

The CASTLE unattended intelligent weighing system adopts intelligent anti-tare cheating methods for the measurement of material supply and finished product sales, and uses intelligent judgment on the tare weight of the vehicle to effectively prevent the possibility of cheating in the tare link.

(5) Anti-cheating module for real-time capture of three images of the front, compartment and rear of the car

The system integrates the image with the weighing software. The image is embedded in the software interface. It can capture three real-time pictures of the front, rear, and compartment of the weighing vehicle when the vehicle is weighed (tare). The software is used for the second weighing. The instant picture of the previous weighing is displayed in the interface.

(6) Automatic voice report module:

The unattended intelligent weighing system has a unique voice weight reporting function, which will broadcast the weight through the voice system after the measurement is completed. After the measurement is completed, the system will automatically announce the weight: “The weight is 8.66 tons”, and then broadcast: “The gross weight (or tare) has been weighed, please leave the weighing platform, goodbye.”

(7) Intelligent gear control system-automatic barrier module

(a) Realize the standardized management of weighing of over-balanced vehicles and the entry and exit control of non-over-balanced vehicles.

(b) The two truck scales and the entrance and exit are respectively equipped with blocking equipment: automatic barriers, blocking rails, anti-smashing coils, vehicle detectors, intelligent switching control units and intelligent controllers.

(c) The intelligent switching control unit can implement three control modes of microcomputer control, manual control and remote control for barriers and railings.

(d) After the legally overbalanced vehicle is weighed according to the procedure, the barriers of the vehicle will be automatically raised and released.

(e) The smart car blocking system has the anti-smashing function. When the vehicle does not leave the railing, the system automatically detects that there is a vehicle under the railing through the ground induction coil and the vehicle detector, and the system automatically sends the railing open signal to keep the railing When the vehicle is turned on, the railing will automatically fall down after the vehicle leaves.

(8) Infrared anti-cheating module:

If the vehicle is in a cheating state: it is not fully weighed, the wheels are rolling on both sides of the scale, there are other counterweights, etc., the system will refuse to weigh and give a voice warning. Such as:

(9) Multi-type, personalized reports

The weighing software can perform data query according to different conditions. Such as: query by vehicle number, query by shift, query by shipping unit, query by time, etc., and can query by combination of conditions. The system can print daily reports, monthly reports and other reports (multiple report formats), and can also print according to the query results, and can make personalized reports according to customer requirements.

(10) Network weighing of multiple truck scales

The system can realize networked weighing of multiple truck scales. The same vehicle can be tare and gross weight on different truck scales. Each weighing data is updated in real time, which effectively improves the utilization rate of truck scales. The system can automatically generate EXCEL reports from the measurement data according to needs, and automatically transmit them to the computer of the designated department via the network.

Second, the unattended weighing management system of the platform scale

For a long time, electronic weighing instruments have been widely used in the bulk material industry. However, these electronic measurement equipment have been stuck at the level of auxiliary manual measurement, manual reading, and re-summarization by special personnel, which seriously lags behind the overall information management process of the enterprise.

Under manual recording and measurement, how to effectively monitor the entire measurement process, prevent fraudulent behaviors, and improve application and management efficiency has become a matter of great concern to business leaders. Some companies frequently replace weighing officers, setting up weighing supervisors, and The installation of electronic monitoring equipment and other methods to monitor the measurement process, but can not fundamentally eliminate fraud. The functional requirements for weighing room management of unattended weighing software for platform scales mainly include functional groups such as automatic reading, video monitoring, data monitoring, infrared monitoring, credit card management, language command management, signal control management, special processing, and real-time query.

1. The business process description of unattended weighing software for platform scales

1. The company’s guard office deploys a computer that is responsible for the issuance and recovery of IC cards. The client can register basic vehicle information. Before non-fixed vehicles enter the factory, the basic information of the vehicle must be registered, such as: supplier, driver, Drivers, product names, and other information, and then the bridgehead staff will issue RFID cards (electronic tags) that can enter the factory to the vehicle drivers, and the drivers can weigh in only after receiving the cards.

2. Before the vehicle arrives on the weighbridge, it must be weighed on the scale according to the sequence of traffic lights.

(1) When the local scale has not been sorted, there are red lights on the sides of the vehicle. When the vehicle is swiped and verified successfully, the green light at the entrance is on, the voice prompts “Please load the scale successfully”, and the vehicle information corresponding to the IC card is displayed On the interface.

(2) After the vehicle is weighed, the front and rear lights are red.

(3) When the weight of the vehicle is stable, the weight data will be automatically saved, and the voice prompt “how many tons of weight this time, please weigh down”, the exit is a green light.

(4) After the vehicle is weighed down, the front and rear lights are red, and the weighing is completed.

3. After the incoming vehicles are unloaded according to the prompts, they need to go to the light weight to carry out the skinning operation.

When peeling back, the system will automatically determine whether the vehicle is over gross, whether it has been unloaded for acceptance and other information. If the vehicle does not complete the corresponding procedures as scheduled, the system prompts that the vehicle cannot be peeled back. If the vehicles have completed the corresponding procedures, the system automatically saves the vehicle. The tare weight information is used to generate a complete weighing list, which can be automatically printed in the light weight room, and the driver takes away a copy of the weighing list.

4. After the vehicle is weighed, the driver can deliver the RFID card (electronic tag) to the relevant staff in the guard room (or the driver may carry it by himself).

5. Unattended solution of platform scale unattended weighing software

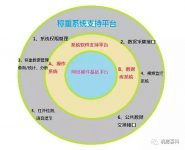

1. The unattended weighing room management system mainly refers to the measurement and weighing performed by enterprises in the process of raw material procurement, product sales and in-plant material allocation. It can be used with RFID (non-contact radio frequency equipment) card swiping systems, video monitoring systems, and infrared monitoring systems. The language command system, LED display system, short message issuing system, and signal control system realize unattended management system. The system can automatically collect gross weight, tare weight information, vehicle weighing pictures, automatic net weight statistics, automatic printing, real-time monitoring of data and pictures through LAN and Internet connection, and the query of the scale can be associated with image information. Company leaders can inquire weighing data on any machine to strengthen the company’s internal management level.

6. Intelligent control system

Can be unattended. This software cooperates with the non-contact sensor swiping technology to realize unattended operation. When the car is parked on the weighing platform, the software automatically collects vehicle information through the swiping device. After the software judges that the weighing data is stable, it can capture the photo and save the gross weight or tare at the same time. Use a camera to take a picture of the driver when he swipes his card, then print the receipt, let the vehicle go, and then start the next vehicle. When a car comes to the tare for the second time, the software automatically calls up and collects the vehicle information. After the software determines that the vehicle is stable, it starts to capture the tare photos and saves the weight at the same time, and then combines the data with the first gross weight data into one Record, calculate the net weight, and then print the receipt. In this way, the gross weight, tare weight, net weight data of the vehicle and the photos when the gross weight and tare weight are saved are saved in the computer, as well as the driver’s card number, which corresponds to the vehicle number one by one. If the vehicle number and the card number on the photo are found to be inconsistent , And the driver’s photo is inconsistent, the driver is suspected of cheating, so the general driver dare not change the vehicle, to ensure that the weighing of the gross weight and the weighing of the tare are the same vehicle.

[ad_2]