High-quality high-temperature label solutions

[ad_1]

Do you know the challenges faced by high-temperature labels in the manufacturing process of printed circuit boards?

Soldering technology occupies an extremely important position in the assembly of electronic products. Generally, soldering is divided into two categories: one is mainly suitable for the soldering of through-hole plug-in electronic components and printed boards-wave soldering; the other is mainly suitable for surface mount components and printed boards. The welding of the board-reflow soldering, also known as reflow soldering. Before choosing the right product, it is very important to understand the harsh environment that high-temperature labels need to withstand during these processes.

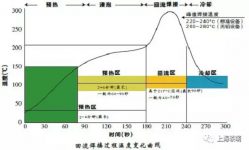

Temperature is the key to ensuring the quality of soldering. The temperature change experienced during reflow soldering (see the figure below) usually contains multiple stages or areas.

Before the printed circuit board (PCB) enters the preheating stage, a solder paste made of powdered solder alloy and liquid flux is applied to the pad to help the electronic components to be attached to the circuit board. Subsequently, the circuit board enters a preheating cycle with a maximum temperature of 150°C (in some applications, there may be a thermal soaking stage to help remove volatile substances and activate the flux).

Next, the PCB is heated to the melting point of the solder, and the molten solder will permanently bond the component’s contacts. During this process, the PCB will be exposed to a peak temperature of around 230~260°C (some manufacturers have transitioned to using tin/copper soldering, which is more cost-effective compared to lead-free solder paste containing silver, but The required exposure extreme temperature can reach up to 280°C). After cooling back to normal temperature, the PCB will undergo a cleaning process using corrosive chemical flushing agents. In extreme applications, the entire process may be repeated many times, so the label needs to be extremely durable.

[ad_2]