Beef tracking system solution based on UHF RFID

[ad_1]

I. Overview

Since 2003, China has begun to apply advanced UHF RFID radio frequency identification technology to modern pig slaughter and processing enterprises, and has developed a real-time UHF RFID pig slaughter real-time production monitoring and management system. The system can monitor the entire production process in real time, automatically, in real time, and accurately collect relevant data about the main production processes and key links such as hygiene inspection and quarantine, which satisfies the HACCP quality supervision requirements. In addition, government regulatory agencies can effectively monitor product quality and safety through this system, track and trace the source and flow of problematic products in a timely manner, and standardize the production and operation process of meat companies, thereby effectively improving the quality and safety of meat products.

UHFThe application of RFID technology in the animal husbandry industry mainly has two aspects. On the one hand, the establishment of an animal husbandry management system for fine breeding of animals; on the other hand, the establishment of an animal tracking management system. Current beef product safety has become a key factor in the beef supply chain. In view of this, more than 20 countries and regions around the world have adopted UHF RFID technology to track and trace their food production processes, and have achieved good results. The UHF RFID-based beef tracking system identifies and connects the management objects in the supply chain such as cattle growth, beef processing, storage, and retail, and then displays these identifications with bar codes and human readable methods. Once a beef product has health and safety issues, these signs can be used to trace, accurately narrow the scope of the safety issue, find out where the problem occurred, and trace the geographic location of the relevant place of production, slaughter or processing institutions, or even individual cattle. In this way, the supply of goods in these places can be blocked from flowing into the market, and then effective governance can be carried out.

One, the solution

2.1 Install electronic ID card

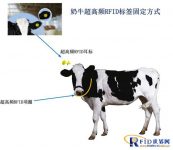

Take dairy farming as an example. The first step in the breeding and tracking of cows based on Kenmax UHF RFID is to install an electronic ID card on the cow, and establish a permanent digital file for each cow with a unique identification. The attributes of each cow. The basic methods for animals to install electronic tags include: collar type and ear tag type electronic tags.

UHF RFID tag fixing method for dairy cows

2.2 Cattle Farm Management System Based on UHF RFID

Write livestock information into the chip, including: livestock owner-owner’s name, gender, animal type, characteristics, immunization, vaccine type, manufacturer, production batch number, vaccination method, vaccination dose, immunization quantity, and immunization personnel’s name, etc. , The owner needs a Kenmax RFID handheld terminal and can obtain information about the livestock. According to the regulations of the Ministry of Agriculture of China, the cattle coding format is: 2-×××××× (county-level administrative area code)-×××××××× (identification sequence number). Other countries should be modified according to the local code.

The specific operation process is: in the daily management of animal husbandry, the owner only needs to carry a Kenmax RFID wireless handheld terminal to read the animal ear tag to be followed, and the relevant information of the animal can be displayed on the handheld terminal come out. Owners can feel this information to deal with their daily diet, medical history, reproductive history, immunization records, etc. accordingly. Fast and convenient, saving a lot of time. There is no need to look up the original acquisition file card. At the same time, the data can be transferred to the back computer, and the livestock file can be established in the back computer. Professionally record the detailed information of each livestock through the computer. No need to worry about illegible records or missing file cards. At the same time, the department and relevant leaders can check the situation of any ranches, stalls, and livestock instantly through the Internet to achieve information transparency.

2.3 Dairy cow precision feeding subsystem based on UHF RFID

The digitization of fine aquaculture is based on a database system. In a distributed network environment, users of various business units can obtain and update data, store and manage data, extract and analyze information, and form basic data through the basic data warehouse mechanism of digital agriculture. Sharing and information mining. The knowledge and experience of precision breeding experts are abstracted, a data model is established to guide dairy cow breeding, and the feedback formed in the breeding practice is used to adjust the model.

The logical structure of the digital system for fine dairy farming is divided into a three-tier system structure: data layer, service layer, and application layer. The data layer is composed of digital agriculture basic data warehouse (including metadata database, image database, comprehensive feed nutrient database), sensor information database (including radio frequency sensor data, video surveillance data, etc.), expert model database and other database groups. The service layer is composed of a digital agricultural precision breeding support platform and an information sharing and exchange platform, including computer network systems, communication systems, monitoring systems, display systems, and operating systems. The application layer mainly includes a variety of application systems, as a client to call database server information and services.

Architecture of Digital System for Fine Breeding

2.4 Meat tracking system based on UHF RFID

UHFRFIDTechnology can be applied to the entire process of animal husbandry food production, including feeding, epidemic prevention and sterilization, product processing, food circulation and other links. Standardized technical regulations and quality supervision measures are fully introduced to establish a “farm to table” food supply chain Tracking and traceability system.

1. The government takes the lead to build a meat food supervision platform, realize the information access and sharing of related enterprises and departments in all links of the supply chain, and realize end-to-end monitoring from the source of production to the retail link.

2. In the cattle breeding link, through Kenmax UHF RFID handsets, RFID tags and supporting auxiliary means, the whole process of feeding and tracking is realized, and the back-end livestock production management system is integrated, and the livestock quarantine with the competent department of the industry is realized The inspection system is docked, and at the same time, relevant information is input into the meat food supervision platform.

3. In the beef transportation link, use Kenmax UHF RFID handsets, RFID tags and supporting auxiliary means to deploy crossing monitoring systems on different transportation nodes to monitor the entire transportation process, and provide pig quarantine inspection and transportation disinfection, etc. At the same time, relevant information is entered into the meat food supervision platform.

4. In the cattle slaughter process, the health status of cattle is verified and confirmed through Kenmax UHF RFID handsets, RFID tags and supporting auxiliary means, and the back-end management system of the slaughterhouse is integrated. At the same time, relevant information is input into the meat Food supervision platform.

5. In the beef processing link, UHF RFID technology is used in conjunction with barcode technology to realize the correlation between cattle information and beef information. At the same time, relevant information is input into the meat food supervision platform.

6. In beef wholesale and retail links, UHF RFID technology is used to accelerate the efficiency of logistics links, and bar code technology is used to trace its source information to strengthen its market transaction management. At the same time, relevant information is input into the meat food supervision platform.

Beef product tracking information flow

3. The advantages of UHF RFID technology in the application of animal husbandry industry

Electronic identification management has been used in Europe and America for several years and has become a showcase of technology. In addition to the application of automatic feeding and output statistics within the enterprise, it can also be used for animal identification, disease monitoring, quality control and tracking animal species. The main advantages of UHF RFID technology in the livestock industry are as follows:

⑴ Non-contact automatic reading, real-time effective data collection method

UHF RFID technology uses a non-contact radio frequency identification method to collect and systematically manage the data placed on the animal’s earlobe or collar. It is an extremely effective management method for grasping the animal’s health status and controlling the occurrence of animal epidemics.

⑵ Unique number, not easy to forge, easy to manage

When the animal is born, the electronic identification is placed on the earlobe or collar of the animal. The electronic identification is one-time use, uniform number, and unique number. Through the traceable management of individual dairy cows, precise feeding is carried out to increase the feed-to-milk ratio; at the same time, health warning and milk quality monitoring are carried out to increase the production of high-quality milk, so as to greatly increase the economic benefits of the enterprise.

⑶Integration with information technology is conducive to tracking management

Through the supporting software management program, the whole process of its growth cycle is monitored. For example, whether it is stocked in a pollution-free natural environment, whether the water, soil, and air indexes meet the standards, the use of veterinary drugs and additives, whether the feed has been contaminated by pesticides or residual additives, etc., and record where it was stocked in different periods. And important information such as its epidemic prevention status and health status. When the food animal meets the slaughter standard, the slaughterhouse will strictly consult the “quality file” of the animal. Only after strict inspection can the slaughter be carried out, and the “file” will be archived for future “quality traceability”.

[ad_2]