Vehicle-mounted gas cylinder electronic label identification and its safety supervision information service system solution

[ad_1]

I. Introduction

my country is the world’s largest producer and application of hazardous chemicals, second only to the United States. At present, the country has more than 100 million hazardous chemical cylinders, including liquefied petroleum gas and natural gas, among which there are liquefied petroleum gas and natural gas. Vehicle-mounted gas cylinders for natural gas are found in taxis, buses, line cars and private cars.

In accordance with the 27th requirement of the State Administration of Quality Supervision’s “Cylinder Safety Supervision Regulations”, the filling unit shall use permanent marks on the gas cylinders to file the property right gas cylinders. As the original steel seal numbers of the gas cylinders currently have different coding rules Unification, duplicate codes, etc. Therefore, in 2004, the State Administration of Quality Supervision, Inspection and Quarantine issued the “Notice on Sampling Inspection Measures for Gas Cylinders General Investigation and Renovation”, requiring the gradual promotion of the use of electronic labeling for gas cylinders; August 17, 2005, the state In the “Notice on the Development of Special Inspection and Rectification Work for the Safety of Hazardous Chemical Gas Cylinders” jointly issued by the General Administration of Quality Supervision, Inspection and Quarantine, the State Administration of Work Safety and the State Environmental Protection Administration, each filling unit is clearly required to implement various safety management systems. , Use electronic tags and other information methods to implement safety management on gas cylinders.

Two, the solution

The construction of this project will be decomposed into two parts in terms of overall technology. The first is the construction of the system platform; the second is the implementation of electronic tags, readers and application systems.

2.1 Project construction goals

The main construction goals of this project are:

1. According to the selection of electronic tags and read-write equipment for the gas cylinder industry, complete the electronic label identification of on-board gas cylinders.

2. Build a vehicle-mounted gas cylinder safety supervision system platform for the government and social safety supervision departments.

3. Provide a safe production management system for electronic tags for vehicle-mounted gas cylinder filling companies and inspection agencies.

4. Provide technical guarantee for the realization of electronic label identification management of on-board gas cylinders.

2.2 Project content

This project closely combines the needs of the construction of gas cylinder safety supervision information service system. The main project contents include:

1. According to the characteristics of the vehicle-mounted gas cylinder industry, determine the selection of electronic tags and readers;

2. Construction of vehicle-mounted gas cylinder safety supervision information service platform, including: data center platform, information service platform, electronic label issuance sub-platform, gas cylinder filling, inspection data collection and exchange sub-platform;

3. Application system implementation. Around the construction of the system platform and each sub-platform, organize the deployment and implementation of related application software.

2.3 Technical characteristics and process route

2.3.1 Features of gas cylinder electronic label

The characteristics of the electronic label of vehicle-mounted gas cylinders include the selection of anti-metal shielding materials and anti-frequency point drifting materials, anti-transfer paste and alloy ABS material shell packaging forms.

Resonance frequency: 13.80MHz±0.2MHz;

Work field strength: not less than 1.5A/m;

Induction distance: not less than 4cm;

Number of reads and writes ≥10,000 times

Working temperature: -20℃— +80℃;

Storage temperature: -40℃— +120℃.

2.3.2 Product Features of Reader

This project adopts explosion-proof electronic tag readers that are used in hazardous situations, supports ISO/IEC15693 communication protocol, contains SAM card module, and uses folding antennas, which can be easily operated in a small space on the surface of the gas cylinder.

Working frequency 13.56MHz±7KHz;

Working field strength 1.5A/m——7.5A/m;

The explosion-proof performance complies with ExibⅡCT4.

Radio interference meets the requirements of GB9254 Class A interference limit;

Radiation interference meets the requirements of GB/T17626.4.

Working temperature -20℃—+80℃;

Working voltage 3.6VDC—4.2VD;

Working current <150mA;

Single key life> 50,000 times;

Number of reads and writes> 10,000 times;

Reading and writing speed <1 second;

Effective working time> 8 hours;

Standby time> 24 hours.

2.3.3 Construction of information service platform for gas cylinder safety supervision

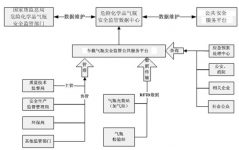

The main contents of the construction of the electronic label-based vehicle gas cylinder safety supervision service platform are: gas cylinder safety supervision data center construction, information service platform construction, electronic label issuance sub-platform construction, data collection sub-platform construction, data transmission network architecture and hardware environment Construction.

The overall framework of the gas cylinder safety supervision information service platform is as follows:

2.3.4 Implementation of gas cylinder safety supervision application system

The gas cylinder safety supervision application system can be divided into four sub-systems: gas cylinder safety supervision information data center management system, label issuance management system, data acquisition management system, gas cylinder supervision information service system and data exchange service support system five Parts. From the structure description diagram below, you can understand the roles and mutual relationships of these five parts in the entire system.

2.3.4.1 Data Center Management System

Establish a gas cylinder supervision information database to provide information for the public inquiries about gas cylinder supervision information and the management of supervision departments. The data elements of the gas cylinder supervision information database will include basic gas cylinder file data, gas cylinder filling information data, gas cylinder inspection information data, and gas cylinder distribution and circulation information in accordance with the construction requirements of gas cylinder safety supervision application system and the business requirements of gas cylinder safety supervision. Data and other safety supervision information content.

2.3.4.2 Data Exchange Service Support System

The data exchange service support system is responsible for uploading the data collected by the information collection system of each filling and inspection link to the data center system. The data exchange service support system is the support system for information exchange and information sharing of the entire information system.

[ad_2]