RFID automatic pig farm feeding system solution

[ad_1]

For a long time, the positioning pen feeding system of the American model has been recognized by most pig farms because of its timing and quantitative, small footprint, and easy management, and has occupied the leading position of my country’s pig raising model. But in the process of its wide application, the drawbacks have gradually emerged. First of all, the positioning pen lactation feeding system greatly restricts the movement of the sows, causing the sows to greatly reduce their motor function in a long-term inactive state, resulting in physical weakness, difficulty in getting into the bed, and a large proportion of dystocia. The decline in physical fitness of sows has led to an increase in the proportion of sows suffering from limb and foot disease. The vitality of the piglets produced is weak, the proportion of stillbirths is large, and the culling rate of sows has increased. The reduction of more than one litter has a considerable impact on sows with only five to six litters. According to statistics, the sow culling rate in both my country and the United States is 35-40%. The small space also makes the left, right, and lower areas of the sow’s body unable to dissipate heat, which is quite harmful to sows and sows in labor within one month after mating. In addition, the positioning fences are all long troughs. After the pigs drink water, the leaked water flows in the trough. Various drawbacks show that the positioning pen feeding system of the American model is not suitable for sow feeding, and we urgently need a brand new feeding method to change this status quo.

The birth of the domestic automatic pig farm feeding system

In May 2010, through the digestion and absorption of European products, after a year of research and development, the “Automatic Pig Farm Feeding System” was born, which has superior functions and is more intimate to use than similar foreign products.

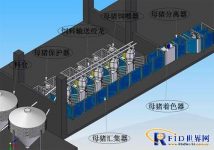

1. The principle of fully automatic pig farm feeding system

The automatic pig farm feeding system is mainly composed of seven parts: sow feeding station, fat pig feeder, piglet feeder, estrus identification system, automatic separation system, remote management system, pig farm ERP management software. (1) Sow feeding station: The fully automatic sow feeding system equips each sow with a unique electronic ear tag, just like a person’s ID card, allowing the system to perform unified management. Each single feeding station can guarantee the feeding of 50 sows. When the sow enters the feeding station, the door of the station is automatically locked, and the pigs outside cannot enter. The detector identifies each pig through the electronic ear tag. According to the different feeding information of each sow in the computer, the feeder puts an accurate and appropriate amount of feed to each sow. In addition, the daily feed intake of each sow is limited. When the sow has eaten the amount of feed for the day, even if it enters the feeding station again, the feeder will not feed any more. Each feeding station is designed with “anti-lying bars” to prevent sows from lying down in the station after they are full. After the sows in the station finish feeding and leave the feeding station, the door lock is automatically opened and the next pig can enter the feeding station.

Figure 1. Single sow feeding station

(2) Fat pig feeder: adopts multi-station design, free-feeding method reduces personnel management, saves feed, promotes the growth of fat pigs, and shortens the slaughter time.

Figure 2. Fat pig feeder

(3) Piglet feeder: According to the digestive function and growth characteristics of piglets, design a feeding mode that eats less and more meals to ensure that the feeder accurately feeds, feeds more professionally, and grows healthier.

Figure 3. Piglet feeder

(4) Estrus identification system: This system can automatically detect whether the sow in the pig house has entered the estrus period, and timely feedback the data to the computer. When the sow that is judged to have entered the estrus period has finished eating and enters the channel, The automatic separator will separate the sow into a small pen, waiting for breeding.

(5) Automatic separation system: The system can separate the pigs that are onset, estrus, pregnancy, parturition, or need immunization, or missing ear tags according to the recognized body temperature, feeding, estrus, etc., so that the corresponding treatment can be taken in time.

Figure 4. Automatic separator

(6) Remote management system: through system software modules, sensors and the Internet, remote video observation, diagnosis and analysis of pigs can be realized.

(7) Pig farm ERP management software: This software not only automatically records the daily feeding, epidemic prevention, heat, fattening, trading and other information of each pig, but also provides the financial management of the entire pig farm and the “import, sale, and storage” of materials Management makes the management of the pig farm complete in one step.

2. Advantages of fully automatic pig farm feeding system

The advantages of the automatic pig farm feeding system in the pig farm mainly include the following points:

(1) It not only breaks the limitation of positioning pen feeding, but also realizes the precise feeding of single sows in group breeding. Each sow can flexibly feed according to its own situation, which avoids individual fighting and realizes The new concept of group feeding and single feeding.

(2) The system replaces manual estrus determination, automatic separation, and epidemic prevention reminders, so that farm management is timely and labor-saving.

(3) The free-range breeding method ensures that the sows have proper exercise and are healthier. The birth weight and survival rate of the piglets produced are significantly increased, the culling rate of sows is reduced, and the economic benefits are more considerable.

(4) The system provides remote management, allowing managers to view various information and current activity status of the pig herd anytime and anywhere.

(5) The system’s unique pig farm ERP management software comprehensively monitors the breeding process, automatically analyzes the breeding effect, provides cost accounting and financial interfaces, so that the entire breeding process can be traced and supervision is more intelligent.

(6) With a thoughtful design of 80W operating power, the battery can drive the entire system with low power consumption and safety, which not only solves the power outage problem but also avoids the risk of electric shock for pigs.

(7) The domestic independent research and development has broken the bottleneck of the high price of similar foreign products and greatly improved the applicability in domestic pig farms.

The future development trend of pig raising

According to statistics, as of the end of 2009, there were about 2,000 large-scale designated pig farms with an annual output of more than 10,000 pigs, and their output accounted for about 7-8% of the country’s total annual output (660 million pigs). It is expected that in the next 5 years, the share of pigs from large-scale pig farms will increase at a rate of 2-3%. By 2015, this ratio will reach about 20%. Large-scale pig farming replaces retail households, and intelligent management replaces manual operations. This is the general trend, and this trend will be even faster in the next five years. In addition, as early as 2008, the European New Food Law stipulated that the comprehensive management and responsibility traceability of the food supply chain (that is, from the farm to the table) should be implemented, and the problematic food will be recalled. This regulation means that agricultural products exported to the EU must not only comply with EU food safety standards, but also expand the food safety management chain. And its special “Treat Animals” welfare clause clearly stipulates that it is forbidden to use positioning pens to raise sows, which puts forward higher requirements for pig breeding companies, thus laying the position of intelligent feeding that cannot be ignored in the future development trend of pig breeding. .

[ad_2]