Pig production and marketing management system project based on RFID technology

[ad_1]

Food is food to safety first. my country is the world’s largest producer and consumer of pork products. The safety of pork food has been paid more and more attention by the state and governments at all levels. In August 2005, a zoonotic “streptococcus” epidemic occurred in Neijiang, Ziyang and other places in Sichuan, which had a serious impact on the development of the pig industry in Sichuan, and also brought a serious threat to the health of the general public. Experts in the industry took the lead in the country. Proposed: The project concept of applying RFID technology to the whole process of the pig food industry chain and establishing a whole-process traceable information management system, hoping to guide the scientific, standardized, and informatized construction of pig breeding, slaughter and processing enterprises through system construction, for the government Regulatory departments strengthened the supervision of live pig food safety to provide guarantees, so that the common people can eat “rest assured meat.”

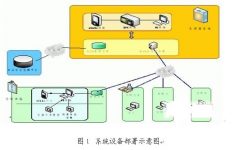

The RFID technology-based pig food production and marketing management system takes RFID technology as the core, combines modern network technology, mobile communication technology and database technology with the current situation of the Sichuan pig industry, and builds an industrial chain from pig breeding, slaughter and processing to distribution and sales. Information traceability management system. Through system application and project implementation, the most effective information management can be provided for breeding pig breeding and commercial pig breeding, slaughter and sales. Provide basic data for the formulation and implementation of policies of relevant government departments, provide a basis for financial insurance institutions to insure breeding enterprises and farmers, provide consumers with true and accurate product information, and eat real “safe meat”. In May 2006, the system construction project was listed as a key project of the National Golden Card Project. In August 2008, the project was included in the first batch of informatization pilot demonstration projects in Sichuan Province by the Sichuan Provincial Development and Reform Commission and the Sichuan Provincial Economic Commission. In March 2009, the project was approved by the National Development and Reform Commission to be included in the first batch of national informatization pilot projects.

The key technology of this system lies in the application of the Internet of Things technology, including three aspects:

1. An RFID middleware system that realizes standardized software products based on RFID information collection, information exchange and application integration, and is applied to the information management of pig food production and marketing management;

2. Two platforms: Establish a platform for pig food production and sales management and quality and safety traceability to realize information collection, production and sales management and quality traceability in pig breeding, slaughtering, processing, and sales. Establish a live pig food RFID e-commerce platform, and realize the information release and transaction payment of pig food based on RFID.

Three. Three types of RFID application specification systems: refer to the use of RFID technology and Internet of Things related technologies to realize livestock and poultry breeding, slaughter processing, sales and other links under the requirements of national and local governments for food safety supervision and product information traceability. The informatization management of the company includes three types of technical specification systems for system construction, management and operation, providing standardized and standardized technical guidance for the application of production and marketing management in the pig food industry.

This system covers the main aspects of the Internet of Things technology research and application promotion, and solves the key issues of the Internet of Things technology in all aspects of the pig food production and marketing management from information perception, information exchange to application integration.

In the implementation of the project, we adopted a combination of “technical research and development + practical application”. An enterprise in Sichuan was responsible for the technical system research and development design, technical maintenance and upgrading, and personnel training. The pig production and marketing company was responsible for the pig breeding required for the implementation of the project. Base construction, technological transformation of slaughter and processing links, construction of sales stores, etc., through the combination of technology research and development and practical applications, continuously optimize and perfect the technical system plan to meet the needs of the development of the pig industry in Sichuan Province, and finally establish pig breeding-slaughter and processing- New model of sales operation management.

In the actual application process, the business model of “company + base + farmer + professional association (cooperative)” is adopted. Implement large-scale production, professional services, and industrialized operations. Establish and improve high-quality pig breeding and seed production systems, develop large-scale farming for farmers, and implement the whole-process monitoring of site selection, construction, feed selection, disease prevention, pig breeding, and pollution treatment, and advanced breeding management techniques of all-in and all-out. Combining the slaughtering, processing, transportation, and preservation technology and equipment of the company, and supporting the chain operation system, it produces and sells high-quality and safe pork products.

After more than 3 years of research and development, the two-generation product research and development of the “Electronic Identification and Traceability Management System for Pig Food Industry Chain” used in the implementation of the project has been completed.

Since the beginning of 2007, companies in the industry have strengthened the construction of pig breeding bases on the basis of their pig food industry chain. By September 2010, more than 30 standardized pig breeding farms have been newly expanded, driven by the new cooperative model of “company + farmer”. There are more than 3,000 pig farmers who produce, process and sell more than 500,000 pigs with RFID electronic tags each year, increasing the output value of the enterprise by more than 5-8 million yuan each year. At present, this system will gradually be promoted and applied in more than 80 branches of Tongwei Co., Ltd. distributed throughout the country, and will surely produce significant economic and social benefits.

[ad_2]