Tianjin Little Bee RFID Smart Weighing Solution

[ad_1]

I. Overview

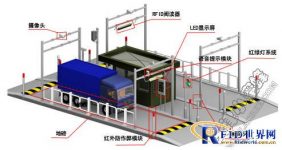

The use of RFID (video recognition) technology can be applied to industrial production and other enterprises that frequently carry out cargo transportation, and can fully realize the intelligent automatic management of vehicle entry and exit, or cargo transportation, and entry and exit of warehouses. When entering and exiting vehicles are registered and weighed , Eliminates the traditional manual recording method, which greatly improves efficiency, saves time and manpower, avoids manual uncertain errors, and realizes the automation of measurement data collection. The system solution starts intelligent metering and real-time video monitoring of the transported goods from the time the transport vehicle enters the scope of RFID identification, ensuring the scientific, accurate, safe, stable, and high-efficiency of the entire process, and fulfilling the requirements of modernization .

2. Background

The Internet of Things industry is a strategic emerging industry that is another information technology revolution after the Internet. It is a new commanding height for global information technology and industrial development in the post-financial crisis era. RFID (Radio Frequency Identification) is an important part of the Internet of Things. It is now widely used in various industries, and some companies engaged in industrial production are still relatively stuck in the traditional way. The parking, registration, weighing and other procedures of these companies are all very important links. The operator manually enters the data into the computer, which is not only time-consuming, but also has a large error rate. It is inevitable that human errors will occur, overweight blockage, and it is also easy to breed human activities. Fraudulent behavior cannot be efficiently managed and controlled, and enterprises will cause a lot of losses and waste of costs, which is not in line with the trend of modern industrialization.

Three, the system process

Enter the vehicle, verify whether the RFID card is valid, then enter the weighing waiting area, verify whether there is a car on the scale, turn on the infrared detector while the vehicle is on the scale, if it is fully loaded, the red light will be on, and the camera will capture the license plate number , And then carefully record the license plate information and weighing into the label, transfer it to the computer control center, and then load and unload the goods.

After completing the cargo loading and unloading operations, the vehicle enters the weighing waiting area and waits for weighing. Then verify whether there is a car, weigh the vehicle, and turn on the infrared detector at the same time to verify whether it is fully weighed. If it is fully weighed, the red light will light up and the license plate number will be captured. The license plate number and weighing information are recorded in the RFID tag to complete the weighing. The green light is on, the vehicle is released, and the vehicle leaves the factory.

Fourth, the main functions of the system

1 Automatic weighing and measurement

Automatically and intelligently carry out weighing measurement and data collection, which can carry out weighing operations for the entire process of entry, leaving the factory and internal allocation, and for common information such as license plate number, name of goods, receiving unit and shipping unit, and cargo specifications. Model, all information is recorded and managed, and specific information modules can be developed and designed according to the actual needs of users, eliminating manual recording, improving efficiency, and avoiding unpredictable errors in manual recording, realizing modern scientific and intelligent recording And management.

2 RFID electronic license plate recognition

The use of radio frequency identification technology (Radio Frequency Identification, referred to as RFID) to realize vehicle identity recognition, the system dynamically collects electronic license plate information during the course of the vehicle. Collect data completely automatically and judge the legitimacy of its overbalance. If it is an authorized legal vehicle, it will be weighed smoothly. If it is an illegal vehicle, overweight weighing is not allowed. Speed up the weighing process to prevent human cheating.

3 Realize the whole process of weighing

Regardless of whether it is in the entry and leaving the factory, or the internal transfer and other work processes, you can do without manual measurement, record analysis, etc., and fully intelligent and automated weighing can be realized.

4 Automatic voice prompt

In the process, important information will be voice broadcast, and different voices will be broadcast in different processes. For example, the voice will automatically broadcast the weight information: “What is the weight of the cargo”, and then confirm it as a legal vehicle. Automatically open the automatic barrier, and announce: “Weighing has been completed, please leave the weighing platform, goodbye”. Friendly reminders and warnings can be set according to specific conditions and customer needs.

5 Infrared anti-cheating

If the vehicle is in a cheating state, is not in the correct position, is not fully weighed, wheels are rolled on both sides of the scale, or there are other counterweights, the system will refuse to weigh and give a voice warning. When the alarm signal is detected, the system prohibits the saving of weighing system data, and the weighing process is terminated. Only the vehicle is in an accurate position, making the process more accurate, safe and stable.

6 Video surveillance

Although intelligent weighing can be unattended and fully automated. However, in order to avoid accidents and ensure the timeliness of information, real-time video surveillance can be carried out, and surveillance cameras can be used to monitor the weighing of vehicles 24 hours a day, and video recordings and screenshots are archived for subsequent inquiries. It can also be connected to the network, and the leaders of relevant departments can perform synchronous monitoring of data and images, query and summarize, and issue orders for specific situations in their own offices, which greatly improves the efficiency of management and realizes centralized management.

7 LED display

The LED display screen can display the weighing weight information in real time, as well as the detailed information of vehicles and cargo vehicles.

8 open interfaces, flexible expansion

The design of the entire system and the development of the software system meet the requirements of various types of internal and external truck scale instruments used by most domestic factories and mines and customs ports. Customize additional functions according to the needs of the enterprise to realize seamless connection with the production system. While realizing the basic functions and standards, the software system has an open excuse to facilitate the deletion of functions and flexible expansion.

Phone: 86-22–27430664

[ad_2]