Intelligent weighing system solution based on UHF RFID technology

[ad_1]

1 Overview

In some large domestic public enterprises and institutions, such as power plants, coal yards, garbage dumps, etc., a large number of material transportation vehicles enter and exit every day, and procedures such as parking, registration, and weighing are required during business processing. At present, these units mainly rely on operators to manually enter data into computers. Manual operation is not only time-consuming, but also has a large error rate. In addition, a weak control environment can easily breed man-made fraud and cause a lot of economic losses to enterprises and institutions. With the rapid advancement of the country’s economic and social construction, this manual-operated work method has gradually been unable to meet the ever-increasing business processing requirements.

According to the urgent needs of these enterprises, combined with all aspects of weighing, adopt more advancedRFIDAutomatic identification technology, combined with network technology and video surveillance technology, creates a more intelligent and informatized enterprise weighing management platform, which can effectively eliminate human error, shorten weighing time, reduce queue congestion, and reduce staff labor intensity. Improve labor efficiency, strengthen corporate management, establish a good corporate image, and realize the improvement of corporate economic and social benefits.

As an agent of Trimble&ThingMagic, Shenzhen Quanshunhong Technology Co., Ltd., based on the advantages of ThingMagic UHF RFID products, has cooperated with system integrators in the field of RFID radio frequency technology to easily realize RFID warehouse logistics management, RFID book file management and other projects. Today we mainly share the application of UHF RFID technology in smart weighing.

2. Technology Application

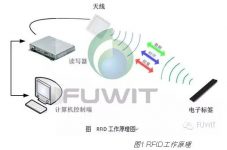

RFID radio frequency identification technology is an automatic identification technology that has revolutionized enterprise automation management after bar code technology. RFID uses the principle of radar reflection. The reader sends a microwave inquiry signal to the electronic tag through the antenna. The electronic tag is activated by the microwave energy of the reader, and responds after receiving the microwave signal and sends out an echo signal with tag data information. The basic feature of radio frequency identification technology is to use radio technology to identify stationary or moving objects, to determine the identity of the object to be identified, and to extract the characteristic information (or identification information) of the object to be identified.

As a non-contact automatic identification technology based on the principle of radio frequency, RFID technology has obvious advantages in recognition speed, recognition distance, storage capacity, reading and writing capabilities, environmental adaptability, and concurrent operation compared with traditional barcode technology. These advantages will bring management changes to the enterprise in the enterprise’s automatic weighing system.

3. System design

3.1 Overall structure

The intelligent vehicle weighing system based on RFID technology is an intelligent comprehensive management system based on RFID technology, which combines the weighing system with long-distance RFID radio frequency identification technology. The system uses electronic truck scales, long-distance RFID radio frequency equipment, automatic barriers, signal lights, etc. to integrate into an intelligent system, which can automatically record the ID number, weight, time, unit and other information of the incoming and outgoing vehicles, and directly write them into the host database. The host can transmit data to the monitoring computer in real time, and the monitoring computer can also call the data in the host database at any time. The RFID intelligent weighing system has a huge role in improving the efficiency of cargo transportation and handling, and making the business management mode more structured, standardized and scientific, thereby improving the management level and reducing costs.

The structure of the RFID intelligent weighing system is as follows:

By installing the RFID electronic tag on the vehicle, the RFID electronic tag information is bound with the vehicle information. After the vehicle is weighed, the vehicle information is obtained through the RFID reader, and then the weight information obtained by the electronic scale is combined with the vehicle information. The vehicle information is bound to complete automatic weighing.

The vehicle information collection tool of the intelligent weighing system, long-distance RFID technology can significantly increase the speed of passing vehicles, and through automatic identification of vehicle number and anti-disassembly measures, it can effectively prevent human fraud from bringing economic losses to enterprises and institutions. In addition, the intelligent weighing system based on RFID technology can also greatly reduce the labor intensity of the staff and the error rate of manual weighing, and improve the transparency of the vehicle transportation management process.

3.2 Process

Enter the vehicle, verify whether the RFID card is valid, then enter the weighing waiting area, verify whether there is a car on the scale, turn on the infrared detector while the vehicle is on the scale, if it is fully loaded, the red light is on, the camera will automatically capture the license plate number, Then the license plate information and weighing information are recorded in the label and transmitted to the computer control center to complete the automatic weighing process.

3.3 System characteristics

Compared with the previous freight yard vehicle management and intelligent weighing systems, the use of RFID technology for freight yard vehicle management has the following advantages:

Information collection automation

The weighing data output by the vehicle scale and the electronic label card number installed on the freight truck are processed by related equipment and then transmitted to the computer. The computer displays the weight of the cargo carried by this car and stores it in the computer’s database. Users can perform operations such as querying, summarizing, and printing according to their needs, thereby realizing information collection automation.

Strengthen management to prevent favoritism and fraud

One car, one card, and the electronic label is affixed to the windshield of the car. The weight weighed on each platform scale corresponds strictly to one card and one car. Cooperate with the camera’s image capture function to ensure that the entire system data is foolproof and accurate.

Can transmit information over long distances

It can carry out remote control and group control to make the system truly automatic and intelligent. It can also be networked with a computer to automatically analyze, calculate and print data records and reports.

Strong data confidentiality in the label

Electronic tags cannot be forged or copied, which fundamentally eliminates the phenomenon of copying, forgery, and cheating.

Establish corporate image, improve work efficiency, and reduce operating costs

The system performs computer automated network management on all truck scales (weighbridges) in the entire cargo yard, which can easily measure the weight of the truck when it is empty and full, and understand the actual weight of the goods loaded on the truck in real time, thereby greatly improving the work of the enterprise efficient.

4. Equipment selection

This system is used in some domestic large-scale public enterprises and institutions such as power plants, coal yards, garbage dumps and other occasions where a large number of material transportation vehicles enter and exit every day. Because the use environment is relatively special, the equipment needs to have good environmental adaptability, and It can ensure efficient and stable work in harsh environments.At the same time, one platform scale corresponds to one RFID read-write device. In the application, a simple and effective integrated reader becomes the first choice.

ThingMagic Astra-EX is an all-in-one UHF reader. It has good environmental adaptability and a receiving sensitivity of -75dBm. The lower receiving sensitivity can still be accurate in the face of on-site environmental interference. Get the label information. ThingMagic Astra-EX all-in-one reader/writer is equipped with a high-performance antenna, which can be deployed more easily and flexibly. It also supports an external antenna, which can be easily implemented for dual-antenna applications under special circumstances.

As a ThingMagic agent, Shenzhen Quanshunhong Technology Co., Ltd. is actively developing the Internet of Things environment in China, focusing on providing customers with RFID modules, RFID readers, RFID handheld terminals, etc. Power consumption, small size, industrial-grade professional, high-performance RFID equipment. As a leading RFID brand-Trimble’s ThingMagic agent, Quanshunhong Technology provides a full range of ThingMagic products.

With a professional technical team, high-quality service and preferential prices, Shenzhen Quanshunhong Technology provides our customers with world-class RFID equipment solutions and high-quality after-sales service.

[ad_2]