Cable and cable tunnel monitoring system based on Internet of Things technology

[ad_1]

1. System overview

The cable and cable tunnel monitoring system of Guangzhou Hongyu Technology Co., Ltd. (National Engineering Research Center for Mobile Communications) monitors the cable temperature, ambient temperature and humidity, water level, smoke, harmful gases, and combustible gases in the cable tunnel. The photoelectric composite cable is used for power supply and information transmission. At the same time, it can realize remote control of the fan, water pump, lighting system, and image acquisition system according to user needs.

2. System composition

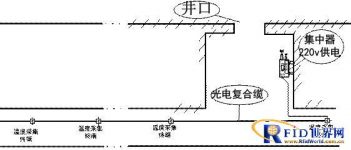

The cable and cable tunnel monitoring system consists of photoelectric composite cables, temperature collection terminals, concentrators, background servers and monitoring centers. Among them, the collection terminal collects the data of each sensor and converges it to the concentrator through the photoelectric composite cable; while the continuous temperature field information is transmitted to the concentrator through the temperature measurement fiber analyzer. The concentrator transmits the control instructions to each collection terminal through the photoelectric composite cable, and the collector controls the wind turbine and other sensors. The concentrator transmits the data to the back-end server through the GRPS network, and the server performs further processing. The processing information is displayed to the detection hall, and the user can also access the processed data information through the Internet.

Cable and cable tunnel monitoring system structure diagram

Technical parameters of main equipment:

Three, system function

Monitoring function:With real-time multi-tasking function, parameter transmission, processing, storage and display can be cycled and run without interruption.

Display print:It has the function of equipment layout and list display, and printing of reports and initialization parameters.

Storage and query:The central host has a data backup function to prevent the modification of real-time data and historical data and other storage contents (except for parameter settings and page editing).

Management function:The center has the functions of man-machine dialogue and operation authority limitation, as well as remote monitoring and query functions of the system.

Safety monitoring:The system has safety control functions for all levels of equipment. The system and each equipment must have lightning protection, anti-static and anti-interference measures.

Self-diagnosis function:When the central host, concentrator, collection terminal and other equipment fails (such as power failure, insufficient power, or communication interruption), alarm and record the failure time and the failed equipment for query and printing.

Software fault tolerance function:The central host shall have a dual-system hot backup function. The device has a parameter power-down protection function and a data temporary storage function. When only a communication interruption occurs, the status information can be temporarily stored and read when waiting for recovery.

Four, performance indicators

System scale: The maximum monitoring distance is greater than 10km.

Maximum inspection period: no more than 30s.

Storage time: The data is stored for more than 3 months, and the length of time when the information is lost in the event of a failure is not more than 5min; the device storage time is not less than 2h.

Two-machine switching time: no more than 5min.

Bit error rate: should not be greater than 10^-8

Screen response time: The response time for calling up 85% of the entire screen should be no more than 2s, and the rest of the screen should be no more than 5s.

Backup power supply working time: After the power grid is cut off, the continuous monitoring time of the system should be ensured not less than 2h.

Control execution time: the control execution time of the safety monitoring equipment power-off and lockout should not be greater than 2s

Guangzhou Hongyu Technology Co., Ltd. (National Engineering Research Center for Mobile Communications)

Phone: 020-84119984

Website: www.mcnerc.com www.mc21st.com

[ad_2]