UHF RFID technology clothing supply chain management system

[ad_1]

1 Overview

In traditional concepts, the clothing industry is a low-tech labor-intensive industry, but in fact, the development of the entire industry is inseparable from the high level of science and technology. From the production of apparel fabrics to apparel design, production, logistics and terminal sales, the support of science and technology is indispensable in any link. Especially in the supply chain management, it is faced with inaccurate inventory information, often out of stock, and unavailability of goods. Tracking and tracing, frequently sending wrong goods, out of synchronization of logistics and information flow, and high intensity of manual work have brought considerable challenges to the operation and management of apparel companies.

In recent years, many apparel companies have also realized the importance of science and technology and have begun to explore supply chain management represented by bar code technology. They have successively scanned bar codes in the storage and inventory links, which has increased the supply to a certain extent. The information level of chain management. Welcome to visit the official website of Chuan Shunhong: www.fuwit.com or call 400-0581-580. However, due to the poor penetration of barcode recognition, it must be detected within a small distance. The barcode recognition process cannot be read in batches. There are many misunderstandings in the bar code recognition process. This is because bar codes are easily damaged and destroyed when printed on paper media. In addition, the information that the barcode itself can represent is too single to describe more characteristics of a certain piece of clothing. There is still much room for improvement in the information management of the clothing supply chain.

2. Technology Application

UHF RFID technology is a new automatic identification technology that reforms the supply chain management mode of the apparel industry after barcode technology. It uses the principle of radio frequency identification, which can work in a variety of harsh working environments and can penetrate certain The obstacle recognition of RFID has good penetrability; it can also identify goods in motion, and can be identified in batches; RFID tags can also repeatedly erase and write data, and the tags can be reused. These characteristics of Shenzhen Quanshunhong determine that it is currently the most suitable industry for the application of RFID technology. In the warehousing and inventory link, clothing is accurately read in batches, which reduces labor intensity and avoids possible errors in manual operations. This brings a qualitative leap in management cost control, rational allocation of resources, and comprehensive competitiveness of the enterprise.

Compared with traditional bar code technology, RFID has significant advantages.

Use RFID technology to solve the current shortage of original boxes and inefficiency in the links from product offline to factory delivery, collection center receipt, sorting and delivery, and realize accurate and fast sorting and packing of clothing products, which is greatly shortened The clothing supply cycle reduces the company’s operating costs.

3. System design

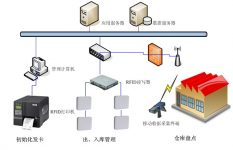

The application of RFID in the clothing supply chain management is to bind the RFID tag to the clothing. In the entire supply chain, the clothing tag information is obtained through the RFID terminal to achieve the purpose of the entire process management of the clothing. The system frame diagram is as follows:

The core process of the clothing supply chain management system based on RFID technology is precise packing, warehouse storage management and warehouse inventory.

3.1 Precise packing

Tags are the basis of the entire RFID system. Each electronic tag needs to be encoded at the front end, and then bound with the clothing to complete the identification of the clothing information by the electronic tag.

Utilizing the uniqueness of RFID tags, sticking, embedding or implanting RFID tags on each piece of clothing can completely solve the problem of unidentified and tracking clothes when packing, and realize accurate packing.

The label is initialized and printed out by the RFID printer. At the same time, barcode information can be printed on the label. For clothing companies with more suppliers, the companies can issue cards in this way and then give the labels to downstream suppliers, and the suppliers complete the binding of the labels and clothing.

Reference icon for actual application:

3.3 Warehouse inventory

The traditional method of using bar code or manual counting one by one, the counting cycle is long, the workload is large, the task is heavy, the speed is slow, the efficiency is low, and it is easy to make mistakes and large errors. The application of RFID technology in inventory can give full play to the advantages of long-distance and simultaneous reading of multiple tags.

Operators only need to download the clothing information to be counted in the background system. After arriving in the warehouse, use the RFID mobile handheld terminal to quickly and accurately compare the system information with the clothing information actually collected to complete the inventory task.

3.4 Extended applications

RFID can also be used in anti-theft applications in warehouses. Install an RFID reading channel at the gate of the warehouse. Any unauthorized clothing products will be identified and alarmed by the system when entering or leaving the warehouse.

The application of RFID technology in the clothing supply chain management can realize the automation of warehouse management, check the inventory of each warehouse at any time, and track the logistics process of the product in time. At the same time, the use of electronic tags can easily realize the accuracy of commodity receipt records and the automation of delivery and distribution, so that there will be no omissions and losses in inventory. Real-time and transparent supply management can provide a scientific basis for clothing sales, production, and stocking while ensuring first-in-first-out clothing.

4. Hardware selection

The clothing supply chain management system based on RFID technology is composed of RFID electronic clothing tags, RFID UHF readers, RFID mobile data acquisition equipment and back-end systems. The system can well solve the circulation management of clothing in all links of the supply chain. Effectively improve the management efficiency of apparel companies, improve service levels, and reduce operating costs.

In this system, the speed and accuracy of RFID data collection are very important. The core equipment is RFID fixed reader and mobile data collection terminal.

4.1 Fixed reader

ThingMagic M6 has a reading speed of 750 tags per second, a powerful multi-tag anti-collision algorithm, and high-speed information reading and processing capabilities, which can maximize the number of garments in and out of the warehouse under the premise of ensuring accuracy.

At the same time, ThingMagic M6 has a small size, high protection level, suitable for harsh working environments, and has a POE function, which is particularly suitable for simple and stable applications in an industrial environment. ThingMagic M6 has an enterprise-level MercuryOS embedded operating system, provides strong software support, and facilitates the docking and compatibility with the apparel enterprise ERP system.

4.2 Handheld device

In this system, handheld devices are mainly used for fast, accurate and efficient inventory. The equipment requires miniaturization, but at the same time good RFID performance and stability should be guaranteed.

ThingMagic M6e-Micro, a UHF RFID mold with ultra-small module structure design and excellent “quick search algorithm”, can be embedded in a variety of commonly used handheld and portable devices. It has a reading speed of up to 750 tags/sec, low power consumption, and quick response after receiving instructions. At the same time, it has an excellent multi-label anti-collision algorithm, which is especially suitable for warehouse inventory; its unique adjustable power from -5dbm to +30dbm can be easily applied to the precise positioning of goods, providing a quick search for designated cargo positions ensure.

As an agent of ThingMagic, a leading RFID brand, Shenzhen Quanshunhong Technology Co., Ltd. provides all major operators and integrators with ThingMagic’s full range of products. At the same time, the company has always provided a professional technical team, high-quality service, and preferential treatment. Price, to provide our customers with world-class RFID equipment solutions and high-quality after-sales service. The company cooperates with major operators and integrators to successfully apply ThingMagic RFID equipment to various applications in various fields such as clothing retail, manufacturing, warehouse management, aviation and shipping, anti-counterfeiting and traceability.

[ad_2]