RFID pig industry production traceability management system solution

[ad_1]

1. Program overview

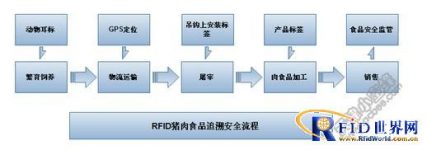

Applying RFID non-contact radio frequency identification technology to the pig industry, RFID electronic tags will record the management and traceability of the whole process from pig birth, breeding, slaughter, and sales. Through the combination of electronic tags and RFID reading and writing equipment, through a unified software system platform, centralized data collection, query, statistics, and analysis are carried out. The whole process is controlled and managed in a planned way to improve the efficiency of health disease control, reproduction and production. Designed in accordance with modern management requirements, convenient, reliable and fast data collection, centralized information management, saving labor costs and greatly improving efficiency.

2. Project background

Food safety has always been a topic of human concern, especially in recent years, a large part of some diseases and infectious diseases are caused by the safety of meat food. On the road of modern agricultural development in China, it has experienced individual breeding to intensive and large-scale breeding, and then the use of modern high-tech information technology to penetrate the management and traceability of breeding and food safety industries. At the same time, the market is also mixed, the order is chaotic, the unified management of government departments is too difficult, and various health problems are serious. The use of RFID technology to manage the whole process of breeding and traceability is the general trend. Pork is the most common meat food on the market, and it is also a concentrated part of food safety. In order to solve the above problems, the RFID business department of Tianjin Bee Company provides a traceability management system for the production of pig industry in response to technological and social development trends.

Three, system composition

The application of production management and traceability based on RFID technology in the pig industry is mainly composed of data management center, system software control center, and finally the management of pig farms, slaughterhouses and sales. The system mainly uses RFID electronic tags, fixed readers and handheld mobile data terminals, as well as a software management system and some additional equipment such as computers. In accordance with the requirements of modern management, design and increase or decrease modules according to the specific requirements of customers.

Four, system functions and advantages

1), reliable data collection

RFID technology has the characteristics of reliability, and the RFID electronic tag itself has the characteristics of large storage capacity, strong reliability, and anti-fouling. The electronic tags used in all aspects of pig breeding are based on the characteristics and processes of the specific environment, making this electronic tag reliable, anti-magnetic, waterproof, anti-static, non-wearing, and the tag can be reused. In order to use RFID readers to regularly scan the health and various growth processes of pigs. You can also use handheld data for targeted inspections.

2), saving production and labor costs

Eliminates manual recording, and has a fast and reliable collection speed. RFID is an intelligent information management method. The feeding farm management module is responsible for the health management and daily management of livestock, and the slaughterhouse management module is mainly responsible for the management and operation of pigs after slaughter. The logistics warehousing module mainly records information such as the time and place before the listing. The sales management module provides query on sales time, query on pork grade and weight sold, query on production date, query on appearance time, etc. The whole system has the characteristics of simple interface, fast response, safe and reliable operation. Centralized data management facilitates the management of its employees and improves its production efficiency and business level.

3), centralized management, improve efficiency

Statistics of all collected and entered data and information. Basic animal information: birth information, breeder information, growth information, entry and exit information, slaughter information and other basic information records; epidemic prevention information: epidemic prevention, vaccination, epidemic prevention inspection, epidemic prevention treatment and other information Circulation link supervision: temperature, humidity, crossing inspection and other information records; slaughter quarantine records: slaughter quarantine, slaughter date, storage environment and other information records; sales product information: sales place information, sales date, distributor information Record; in the future, it can be inquired through a more friendly interface, and various reports can be generated. Help daily management and operation.

4), safer and more epidemic prevention, reduce diseases

Using RFID technology to track the whole process, effectively avoiding diseases caused by the quality and safety of pork. Animal diseases can be detected in time and dealt with as quickly as possible. The vaccination of pigs and the prevention and management of diseases are also predictable. Epidemic prevention information will be recorded in real time, including the records of epidemic prevention, vaccination, epidemic prevention inspection, and epidemic prevention treatment.

5) Traceability and tracking management

The entire process, from the birth of the pig to the slaughter, the transportation process to the sale, has been tracking and tracing management. Any problem in any link can be accurately found, and the relevant responsible person can be clarified, so as to avoid the problem of not being able to find the cause and personnel, which brings aspect and accuracy to the management.

6) Statistics and supervision of national departments

This system can also facilitate the statistical supervision of relevant national departments. In the process of market supervision, the supervisory department requires that the cargo pallets, packaging boxes and price tags of all sales outlets contain RFID electronic tags, and the meat’s origin, product name, Type, grade, price and other relevant data are written into the electronic label. RFID solutions can ensure high-quality data exchange in any supply chain, allowing the food industry to achieve the two most important goals: thorough implementation of source food tracking solutions; and the ability to provide complete transparency in the food supply chain.

7) Enhance the visibility of the company and establish a brand image

Food safety is a topic of great concern in modern society. Many well-known companies have caused consumer health problems and consumers’ dissatisfaction and panic towards the company’s colorful foods, especially this kind of meat like pork. food. This system makes full use of modern high technology and the most important RFID technology of the Internet of Things to carry out safe and standardized information management. Effectively enhance the trust of consumers, increase the company’s reputation in the industry, establish the company’s brand image, and provide consumers with guaranteed and safe pork.

8), perfect software system management function and scalability

This RFID technology-based pig production traceability software system adopts B/S architecture, modularized centralized management, and a more user-friendly and friendly operation interface. According to the specific development of the customer, the corresponding module is developed, and the daily management of the query, transaction processing, High reliability and interoperability, data integrity, rich scalability, new modules can be added, and interfaces reserved for connection with other systems. Statistics, inquiries, and various reports can be formed.

[ad_2]