RFID pork food traceability management plan

[ad_1]

The mad cow disease, clenbuterol and other public events that have shocked the world in recent years have not only brought immeasurable disasters and economic losses to mankind, but also made animal food safety one of the focal issues of global concern. Strengthening the supervision and management of animal food safety and solving the problems of animal food safety as soon as possible has become a very urgent task at present. At present, all animal husbandry farms are looking for and adopting various methods to strengthen the identification and tracking management of animals in order to improve the value of their products and market competitiveness.

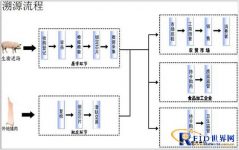

An animal identification and traceability system has been developed through RFID technology, mainly to track and monitor the feeding, transportation, and slaughter of animals, and to trace animals when an epidemic breaks out. The health department can trace the animals that may be infected with the disease through this system to determine their ownership and historical traces. At the same time, the system can provide real-time, detailed and reliable data from birth to slaughter.

RFID food traceability management

1. Breeding link-the piglet wears an ID card

Applying a breeding traceability management system in a pig farm, each piglet is marked with a radio frequency identification after birthRFIDThe electronic ear tag of the chip, as the unique identification of each pig, records in detail the date of birth, breed, ear number, source, and health status of each pig. The administrator uses the RFID reader to scan the electronic tag at any time. View relevant information and import it into the breeding traceability management system for data collection

During the growth process of piglets wearing electronic ear tags, the breeder uses RFID handsets and rfid access control to automatically read the ear tags, record immunization, medication, feed, and turn to the pigs, and pass them to the breeding traceability management system; At that time, use the RFID handset to read and view the management information of each pig during the growth process, record the date of sale of each pig and the place where it was sold, and send it to the breeding traceability management system, fill in and report it to the system on time and truthfully This system can not only meet the information management of modern pig farms, but also meet the needs of food safety traceability for origin traceability.

2. The slaughter link-interlocking is guaranteed

This link includes three links: pig acceptance, slaughter, and carcass segmentation.

Live pig acceptance: Inspect live pigs and read the RFID information recorded during the breeding stage to realize the information of the production site, the disinfection status of the transportation process, the breeding status, the slaughter permit, the disinfection of the live pig unloading, pre-slaughter monitoring, and acquisition The management and control of a series of information such as district disinfection and disinfectant testing ensures that the status of each live pig is mastered in detail. When purchasing live pigs, read the information on the RFID electronic ear tags carried by the live pigs through the RFID reader, realize batch collection of breeding traceability information and import the traceability system, through the analysis of the read information, refuse the purchase of live pigs that do not meet the health and safety standards .

Slaughter: In this link, RFID tags are used to distinguish pig batches in time, and information such as weight, grade, inspection, etc. are recorded. If the inspection information found does not meet the health and safety standards, the pork cannot enter the next production link, and it will be carried out according to the company’s regulations. The harmless treatment achieves the purpose of traceability and management of the product slaughter process.

Carcass segmentation: This step is to segment the pre-cooled pig carcass into small pieces to meet customer needs. When the carcass enters the division room from the pre-cooling acid discharge room, the batch number and weight of the carcass are recorded through the RFID reader terminal, and the processing team, meat grade, weight, batch and other information are recorded with the RFID tag, and the computer or handheld computer is used Associate the data with the background computer and import it into the segmentation traceability system.

3. RFID warehousing logistics link-RFID cold chain logistics can be monitored

In this link, relying on RFID cold chain technology, it carries the traceability management of Rfid warehousing and logistics information. In the logistics link, advanced technologies such as RFID, GPS, GPRS, and GIS are comprehensively adopted. On-board traceability terminals are installed on the logistics vehicles, and temperature tags are placed to monitor the path, vehicle speed, temperature and other information in the process in real time, automatically record, and provide early warning services. GPRS returns the data to the traceability platform in real time.

4. RFID terminal query-scan the tag to see the whole process

The terminal query system is the ultimate display method of the food safety traceability system. Consumers, enterprises, and government users can understand the status of the product in the breeding process, production and processing process, storage process, and transportation process through the query terminal. It adopts a wall-mounted structure, liquid crystal display, Scanning and reading of RFID tags. Once there is a problem with the food, the entire batch of food can be traced upwards according to the traceability code on the single product, and all the sales locations of the batch can be found through the traceability system, and the sales of the batch of problematic foods can be stopped. At the same time, the terminal query system can Satisfy consumers’ right to know and choose right of food, so that consumers can feel more at ease when buying food.

Hardware composition

1. Install RFID fixed reader & long-distance RFID external antenna in the feedlot, real-time monitoring and recording of piglet feed information, epidemic prevention information, medication information, environmental information, etc., to establish complete individual pig breeding files .

2. Install a complete set of RFID warehouse management system in multiple links such as processing, warehousing, and distribution to automatically read and record the real-time information of pork in the assembly line.

The basic configuration is as follows:

3. The relevant departments of epidemic prevention and product quality inspection are equipped with RFID handheld readers to supervise the entire process of livestock species and feed, epidemic prevention and quarantine. At the same time, consumers can also inquire about all the information on breeding, slaughter, and circulation through the computer, so that they can really eat “rest assured meat.”

[ad_2]