RFID production line management management plan

[ad_1]

RFID radio frequency identification is a non-contact automatic identification technology, which automatically recognizes the target object and obtains relevant data through radio frequency signals. Short-distance radio frequency identification does not require manual intervention, and is not afraid of harsh environments such as oil stains and dust pollution. It can replace bar codes in such environments, for example, when used to track objects on the assembly line of a factory. Long-distance radio frequency products are mostly used in traffic, and the identification distance can reach tens of meters, such as automatic toll collection or vehicle identification.

The advantage of ID application in the retail industry is that the use of RFID barcode technology makes tens of thousands of commodity types, prices, origins, batches, shelves, inventory and other information transparent.

1. Specific application of production line management based on RFlD

In order to produce better quality products, while reducing production costs. And to meet the requirements of ISO 9000, manufacturers are more careful to track product information and spray volume control belt lJ process, which requires manufacturers to implement RFID.

RFID is entering the core of the manufacturing process. By gradually adopting RFID technology at the factory floor level, manufacturers can directly and uninterruptedly obtain information captured from RFID and link to the existing, verified and industrially enhanced control system infrastructure, and coordinate with the supply chain equipped with RFID functions Therefore, without updating the existing manufacturing execution system (MES) and manufacturing information system (MIS), it is possible to send accurate and reliable real-time information streams, thereby creating added value, increasing productivity and greatly saving investment.

2. Processing of real-time effectiveness of information management

For manufacturers, timely and accurate feedback information from the production line is very important. In the past, the information could only be calculated after the end of production, which was time-consuming and laborious, and sometimes human error was inevitable.

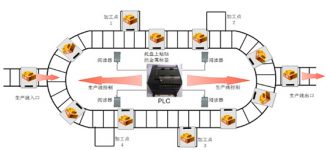

If RFID reading equipment is installed at each node of the production line, and RFID electronic tags that can be read and written repeatedly are placed on the products or trays. In this way, when these products or pallets pass through these nodes, the RFID read-write device can read the information in the labels on the products or pallets, and feed these systems back to the back-end management system in real time, so that manufacturers can easily Keep abreast of the detailed working conditions of the production line. Moreover, by combining RFID with existing manufacturing information systems such as MES, ERP, CRM, and IDM, a stronger information chain can be established to transmit accurate data in time at the correct time, thereby enhancing productivity and improving productivity. Asset utilization and higher-level quality control.

3. Application in manufacturing management process

Because RFID can provide continuously updated real-time data stream of MODERNBUSINESS, combined with the manufacturing execution system, the information provided by RFID can ensure the correct use of labor, machines, tools, and components. With this kind of timely and accurate information management, paperless and contracted production is possible, and it can greatly reduce the downtime of the production line and improve production efficiency.

If there are a batch or even several batches of contract products, the same production line needs to be used for plus T production, but only some parts are slightly different. In the past production methods, the only way to produce products of the same model was to shut down the production line, make adjustments, and then produce another model of product, which caused losses.

By implementing the RFID system, products of different models can be coded and written into the RFID electronic tags. When products of different types enter the processing point, the RFID read-write equipment reads the information in the RFID active electronic tag, so that the processing equipment can confirm which type of product to process. If there is an automatic sorting conveyor, by identifying the RFID tag, the product classification can be easily completed, so that the product can be sent to the correct production line.

Fourth, the application of RFID technology in production logistics management

Manufacturing includes not only purchasing and sales, but also the manufacturing of converting low-value materials into high-value-added products. Quick response (Quick Response) and agility (Agility) are the key factors for the success of the manufacturing industry. The production logistics is the core link of the entire logistics of the manufacturing industry. The production logistics and the production process are synchronized, which is the logistics activity of the whole process from the purchase of raw materials to the delivery of finished products. Raw materials, semi-finished products, etc. are constantly moved and transferred between various processing points in accordance with the technological process, forming a production logistics. It is a unique activity of the production enterprise that manufactures the product. If the production is interrupted, the production logistics will also be interrupted, and vice versa.

With the help of RFID technology, the electronic tags on raw materials, parts, semi-finished products and finished products enable production planning managers to quickly locate them and understand the consumption of raw materials. This will greatly improve the efficiency and quality of production; at the same time, RFID technology can also Collect and process product information to help production personnel easily grasp the operation of the entire production line and further accelerate the production progress of the product. Due to the readable and writable nature of RFID, it can provide a constantly updated real-time data stream. Complementing the manufacturing execution system, the information provided by RFID can be used to ensure the correct use of labor, machines, tools, and components. So as to realize paperless production and reduce downtime, and promote the smooth progress of production logistics.

Furthermore, combining RFID with existing manufacturing information systems such as ERP, CRM, etc., to establish a stronger information chain, and to achieve timely delivery of accurate data at an accurate time, thereby improving asset utilization, enhancing productivity, Perform various online measurements and support quality control.

Fifth, carry out accurate information tracking

Compliance with FDA quality regulations will encourage manufacturers of consumer packaging products, food, and beverages to accurately track and trace product information throughout their entire supply chain. Nowadays, due to the negligence of a certain link, products with quality problems enter the market. These quality problems, the most serious ones, may threaten the lives of consumers. Therefore, it is not uncommon for manufacturers to recall products. Thanks to the help of the RFID system, with accurate and timely information feedback, manufacturers can quickly inquire the production date, contract number, source of raw materials, and production process of the problematic product, and can even be accurate to a certain problem according to needs. Product information. In the manufacturing industry, product (tray) identification, intelligent conveyor path selection, date and production time verification, automatic guided vehicles, batch production formulas and other links, the application of RFID systems can achieve real-time information management and flexible Manufacturing management, accurate tracking and tracing of these goals, and improving the level of automated production, production efficiency, making production management more flexible, and ultimately benefiting manufacturers.

Sixth, large-scale manufacturing companies implement RFID recommendations. The application of RFID technology will bring huge revenue prospects.

But along with huge benefits, it will also bring huge challenges to implement this new technology. Therefore, for large-scale manufacturing enterprises, before implementing RFID technology, it is necessary to make a pre-planning to lay a solid foundation for the successful implementation of RFID systems in the future.

1. Cost/benefit analysis.

A cost/benefit analysis report is very important to the successful implementation of RFID. The current implementation of RFID technology still has problems such as cost, technology, standards, etc. Some companies are still on the sidelines to implement RFID technology; but RFID technology can bring huge benefits, including indirect benefits, such as improving customer satisfaction. These should be included in the report, and the investment income analysis should be carried out according to the actual situation.

2. Application system analysis.

Before implementation, it is necessary to clarify the business requirements for deploying the RFID system and analyze these requirements. At the same time, we must fully consider the various factors in the development and deployment of RFID systems, and make overall plans. After the plan is completed, the plan must be handed over to those who have real decision-making power to ensure that they will be truly implemented.

3. Formulation of implementation plan.

Develop an RFID implementation plan based on the analysis report of the application system. The implementation of RFID projects is generally divided into four feasible phases of the plan, gradually achieving a smooth and slow transition. Namely: four stages: start, test and verification, pilot implementation and actual implementation. For large manufacturing companies, the key lies in how to use RFID information to achieve information integration with the company’s existing systems, optimize internal business processes, and improve the company’s core competitiveness. Although it is not easy to implement RFID, it is sometimes necessary to reorganize existing production lines, conduct high-quality staff training, and conduct regular inspections on software systems and hardware equipment, and so on. However, the application of RFID technology will bring huge benefits to companies with a very modern corporate management awareness.

[ad_2]