Power inspection system solution

[ad_1]

1. System overview:

The power equipment inspection system is a basic work to effectively ensure the safety of power equipment, improve the reliability of power equipment, and ensure the minimum failure rate of power equipment. At present, manual inspections and manual paper media recording are commonly used in China. These methods have many defects such as many human factors, high management costs, inability to supervise the work of inspection personnel, and low degree of informationization of inspection secretaries.

The RFID power inspection program introduces the current advanced RFID radio frequency identification technology + GPS (satellite positioning system) + CDMA/GPRS technology, which mainly solves the following three important problems in the equipment inspection work: 1. The inspection is not in place, missed, or Not on time; 2. Manually filling in the inspection results is inefficient, prone to missing items or errors; 3. It is difficult for managers to understand the line status in a timely, accurate and comprehensive manner, and it is difficult to formulate the best maintenance and repair plan.

2. The working principle of the system:

When the inspector is out for inspection, through the handheld machine, automatically (every 2 minutes, the interval can be set) or manually send a message to the center to report the current inspector’s location, time and other information. If a fault is found, the The fault type, device number and current handheld RFID information are sent to the monitoring center.

The monitoring center receiver receives the reported information and stores it. The system reads the information received by the receiver through the system, breaks down the time, location, equipment type, and discoverer of the fault, and automatically stores these data information in the database server and publishes it on the Internet at the same time.

The monitoring terminal uses the RFID system to display the inspection status in real time on the software, such as displaying the fault points found by each inspector, the emergency situation of various faults, the processing situation, the current status, and the location of each inspector at a certain moment. Inspection route.

The poles are affixed with RFID tags, and through a globally unique identifier, the inspectors must go to the scene in person to obtain the RFID identification code, thereby restricting the actual inspection of the staff. At the same time, first input the longitude and latitude of each base tower and other related data of all the lines that need to be patrolled into the server and the handheld. Whether the data is consistent with the original input data, at the same time, record the patrolled information in the handheld, and input the recorded information into the server through the CDMA/GPRS network after the patrol or on the spot, and conduct a comparative analysis. In this way, abnormal conditions in line operation can be discovered in time, so that they can be dealt with in the shortest time, thereby ensuring line safety. Since the data collected during the inspection needs to be input into the server for comparative analysis, it can effectively promote the improvement of the quality of line inspections, ensure the arrival rate of line inspectors, and prevent missed inspections and inadequate inspections.

The system can also perform statistics, summary, and analysis of various historical data stored in the database, and display the frequency and object of a certain fault in a certain period of time in the format of various charts or reports, for the management personnel to analyze through prediction Strengthen management and formulate response measures to achieve the purpose of prior control in order to reduce the incidence of accidents and ensure the smooth progress of safety and mass production.

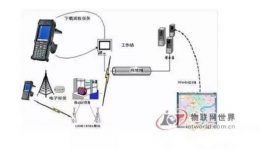

3. System Topology:

4. System advantages:

1) High weather resistance: it can withstand wind, sun and rain, withstand huge temperature changes (usually -30~70°C), and even withstand flooding;

2) Strong adaptability: the automatic identification can be read in harsh weather conditions; the automatic identification reading is not disturbed by the environment of the substation;

3) Strong anti-counterfeiting ability: the logo cannot be copied and counterfeited to avoid the occurrence of artificial cheating;

4) Convenient installation: it can be directly buried on the cement base, the installation equipment is simple, and the process is simple;

5) Strong resistance to destruction: able to resist ordinary man-made destruction; able to prevent malicious destruction by children or livestock;

6) Long service life: The service life is more than 10 years;

7) Convenient operation and maintenance: maintenance-free, reducing management costs;

[ad_2]