Application of Siemens barcode reader in automobile engine production line

[ad_1]

1. Project introduction

The rapid development of the domestic automobile industry has gradually changed from the early small-batch mass production to the multi-batch-to-order production method. The demand for traceability and flexible production of products in the automobile production line is increasing. Due to its own high data capacity, high reading rate, and direct coding on metal surfaces, the two-dimensional code has become a standard product tracking method in the automotive engine industry.

Shanghai GM Dongyue Automobile Co., Ltd. is the production base of Shanghai GM in Yantai. Annual production of 240,000 vehicles, 360,000 engines and 300,000 automatic transmissions. As an important part of Shanghai GM’s automobile development strategy in China, it will build a lean, flexible, modular, and agile factory that can produce high-quality products.

Jinan Zhongzheng Golden Code Technology Co., Ltd. specializes in the research and development, production and sales of marking equipment. The company’s products include: pneumatic marking machines, scribing marking machines, concave-convex marking machines and laser marking machines, including 4 series and more than 20 varieties. It is widely used in the auto parts industry, aerospace, military industry, and petroleum industry.

The second phase of the Shanghai General Motors GF6 project valve body line transformation project will add a new production line on the original basis. Because the machine tool itself cannot realize the communication with the IT upper computer, and the PMC dark light, traceability and other functions cannot be realized, it will be in The line point on the line, that is, OP05 station adds a set of traceability system to realize code reading traceability, PMC and some error-proof functions. In this engine traceability system project, Jinan Zhongzheng Golden Code uses Siemens’ code reader product MV440 to read the two-dimensional code generated by the laser marking machine on the surface of the engine valve body.

1. Brief process introduction of the project.

1. The operator puts the workpiece on the reading position

2. The sensor senses that there is a workpiece, and the code reader reads the code and verifies the model of the workpiece (via QR code)

3. When the code is read and verified successfully, the indicator light is on; if the code reading or verification fails, the HMI displays the prompt content, and the bamboo lamp starts to flash.

4. The operator takes away the successfully read workpiece and puts it into the OP10 machine tool, if the model matches, it will start processing

5. If the code reading or verification fails, you can re-read the code or require manual intervention by the operator

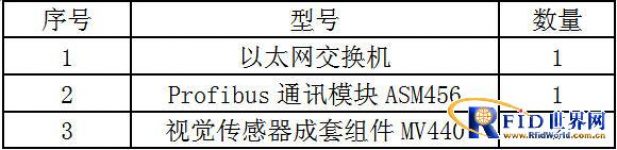

2. Information on the model, quantity, type, and control objects of Siemens automation products used in the project.

2. Control system composition

Valve body two-dimensional code traceability system A Siemens fixed two-dimensional code reader MV440 and a workpiece detection switch are installed at the OP05 station. Each valve body to be online has a laser-printed DATAMATRIX code. The operator puts each valve body to be online on the code reading workbench, MV440 reads the QR code information on the valve body, and transmits the QR code information to Siemens PLC (CPU3152 PN/2DP) through ASM456, PLC Analyze the information of the workpiece and pass it to each CNC machining center of OP10-OP50 station through I/O, so that after the processing is completed, each machining center will bind the processing data with the information of the workpiece to realize the process of processing. Traceable.

SIMATIC MV420 / MV440 is a high-speed, high-reliability code reading product, and a fixed one-dimensional/two-dimensional code reader with a wealth of communication and connection methods. This product integrates the advantages of SIMATIC VS130-2 and HawkEye 1500 series products. It can not only read standard high-contrast bar codes and two-dimensional codes, but also can be used to read DPM codes (Direct Part Marking) under harsh industrial application conditions, that is, direct coding on the surface of the object (through laser etching, inkjet, mechanical printing) The code directly marked on the surface of the object by means of labeling or chemical corrosion).

MV440 barcode reader and PLC provide two communication methods: RS232 socket, ASM socket and Ethernet socket. This project is connected to the PLC through two paths: connecting with ASM456 through profibus and PLC for data transmission, and connecting with Siemens switches through ENTHERNET and PLC for image monitoring.

Introduction to Profibus:

3. Functions completed by the control system

1. Use MV440 to read the QR code information of the valve body

2. Display the read information through HMI

3. If the QR code is damaged or cannot be read for other reasons, enter the part information manually

4. Transmit the read information to five other machining centers to achieve component traceability

Fourth, project operation

The two-dimensional code traceability system was officially put into use in July 2010 and has been operating stably so far. In the actual commissioning process of the project, the complete technical documentation and good technical support of Siemens products made the on-site commissioning process very smooth, shortened the commissioning time, and lowered the project cost.

[ad_2]