Manufacturing warehousing logistics management system

[ad_1]

I. Overview

Jiangsu Junyi Internet of Things Co., Ltd. is a private high-tech enterprise integrating scientific research, production and sales. It specializes in system integration and product development of Internet of Things information technology, including core chip packaging in the RFID field, serialized antennas, and smart cards , The development and production of readers, providing management solutions and services based on the Internet of Things for customers including government, military and industry.

The “Manufacturing Warehousing and Logistics Management System” solution launched by Junyi Internet of Things integrates barcodes,RFID, Wireless sensing and intelligent monitoring technology can easily realize the scientific management of supply chain, warehousing, production and logistics, which greatly reduces the cost burden of enterprises. Through the automatic data collection of raw materials and finished products in the entire production and circulation links, it is ensured that enterprises can timely and accurately grasp the logistics data and safe production in production and circulation.

Second, the system architecture

The entire system architecture consists of the following parts:

1. From raw material warehouse to production workshop

Before the raw materials enter the production workshop, the RFID tags (or barcodes) on the raw materials are identified through the handheld PDA device, and at the same time, the raw material inventory quantity and other relevant information are updated in the production database before entering the production process.

1) In the finished product packaging workshop, the worker first sticks the RFID tag on the product packaging bag;

2) Use the RFID read-write device to write the attributes of the finished product into the label (product name, production date, production batch, etc.);

3) The goods are passed through RFID by the loading and unloading tools ReaderThe channel formed by the antenna is warehousing, and the RFID equipment automatically obtains the warehousing quantity and records it in the system, and the system calculates the location (or manually specifies the location for the batch warehousing at the beginning), and orders the inventory through the network system Send it to the transportation terminal (or forklift truck system) in the finished product warehouse, and the forklift personnel will store it in the corresponding storage location as required. After the storage is completed, the system will update the inventory information and mark the location information of each batch of goods.

4) The system automatically publishes the finished product information on the electronic trading platform for customers to choose and accept customer orders.

2. Outbound delivery of finished products

After the e-commerce platform obtains the customer order information, the distribution center starts to check the inventory quantity of finished products, and if the inventory can meet the supply, it will start preparing for distribution.

1) Confirm the storage location of this batch of goods according to the order requirements, and then accurately find the required goods and quantity through the forklift vehicle system, and load the truck after confirming that the handheld PDA device is correct, and update the finished product quantity and storage location in the database at the same time information

2) In order to ensure that the goods can reach the customer safely and on time. A more effective and simple operation is to seal the goods of the whole vehicle with RFID tags before the goods leave the warehouse, verify the quantity of the goods after loading, and confirm that the goods list is correct;

3) The shipper uses a handheld PDA device to write information such as the license plate, model, driver’s name, cargo type, quantity, customer name, location, and departure time of the transport vehicle in the seal RFID tag;

4) The handheld PDA can upload the collected RFID tag data information to the background database system through wired or wireless (WIFI) transmission, and then the operator will publish the data to the website, so that the customer can grasp the received goods information in a timely manner. Check and confirm upon arrival.

3. Inventory check

The staff can use the handheld PDA for regular inventory, read the label information of the goods at close range, and compare it with the database management system, and manually check whether the variety, quantity, and production date of the goods in the warehouse are consistent with the back-end system. If they are inconsistent, the system information can be corrected on site. This inventory method can shorten the enterprise inventory time by 85%, greatly improve work efficiency, and at the same time increase the inventory cycle.

4. Production and circulation process monitoring

In the production and circulation process, wireless digital humidity and temperature sensors and monitoring equipment are used to ensure the safety of goods and production. Monitoring cameras and humidity and temperature sensors are installed in the warehouses and entrances and exits of the raw materials and finished products warehouses, and the components and positions are marked in the management system. And set the critical state of humidity and temperature data. The sensor is connected to the system via WIFI, and the data is reported to the management center in real time. When the system finds that a certain data reaches the critical value, an alarm signal will be sent out and processed by manual intervention to ensure production And warehouse security.

5. Other management functions of the system:

1) Report function

2) Personnel and vehicle management

3) Supplier and customer management (this part is shared with the trading platform)

4) Assistant decision management

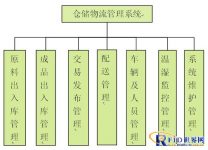

Three, system composition

1. Software system

1)windows 2003 Server

2) MS SQL Server

3) Warehouse logistics management system

4) Handheld PDA terminal software (embedded)

2. Hardware system

1) RFID (925MHz) fixed reader (ISO18000-6B/C)

2) RFID channel

3) PDA (support RFID tag reading and writing and read-only one-dimensional code and two-dimensional code)

4) RFID paper label (for finished product packaging)

5) RFID card (personnel management)

6) Wireless digital humidity and temperature sensor

7) HD camera and video server (blade server)

[ad_2]