Design scheme of single chip fingerprint lock

[ad_1]

The way people use locks is constantly changing. From mechanical locks to electronic locks, the lock industry has taken a huge step, and it has also brought major improvements to people’s lives. Now, the rise of “biometric technology” on a global scale is driving another technological innovation in the lock industry, which will surely lead the era of “fingerprint locks”.

According to the statistics of lock industry experts, the current national lock sales volume is about 2.2 billion or more per year. After several years of market brewing, the market demand for fingerprint locks is increasing day by day. According to estimates, the commercial market, including finance, military and police, and office, has a market demand of about 5 million sets each year. After the civil market matures, there will be at least the demand for the commercial market every year. In the next few years, fingerprint locks will occupy the largest share of the lock market, becoming a turning point for China’s lock industry.

It is in this market background that Singapore Lanke Co., Ltd. has launched the SIB8132 fingerprint recognition chip that can be used with fingerprint locks. Here, I will share the design experience of this professional fingerprint recognition chip with readers.

Overall design

Strictly speaking, the fingerprint lock is a kind of electronic lock. Just because it is based on fingerprint recognition technology, it has abandoned the “password” and “smart card” of the previous electronic locks, and used the human body’s inherent biological characteristics-fingerprints, thus achieving the perfect unity of technology and human nature. The fingerprint lock not only satisfies people’s demands for safety, but also keeps people away from the worries of “memorizing passwords” and “carrying cards and fear of losing them”. It can truly be “safe and convenient”.

To realize this “safe and convenient” fingerprint lock, the following aspects need to be considered in the overall design of the product.

First, in terms of “safety”, not only anti-destructive unlocking should be considered, but also anti-technical unlocking should be considered. The fingerprint recognition module is used to eliminate the key unlocking method and basically eliminate the problem of technical unlocking.

Second, we must consider the re-coding rate, or the amount of key. For electronic locks that use information coding, the amount of key is generally no less than 105. For those adopting biometric technology, the key volume is more than 256 bytes. Its password strength is far greater than existing passwords.

Third, the performance of the selected fingerprint identification and fingerprint acquisition devices directly affects the security and ease of use of the fingerprint lock. Although the “fingerprint key” is very strong, theoretically and in practice, misunderstandings still occur, but the probability is much smaller than that of passwords and mechanical keys.

Fourth, does the fingerprint lock increase the cost? Compared with smart card locks and fingerprint locks, fingerprint locks do not increase much in cost. Especially after adopting the SIB8132 single-chip solution, the control program of the lock and the fingerprint identification program can be integrated into one MCU. This is currently the world’s only single-chip design scheme, which has been implemented by many companies.

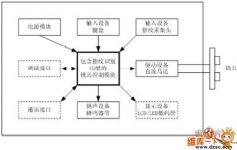

Figure 1 is a block diagram of a more comprehensive fingerprint lock solution. As can be seen from the figure, the lock control module with built-in fingerprint recognition function is SIB8132. It is the core of the entire fingerprint lock. SIB8132 is a 32-bit low-power dedicated processor with built-in 256K ROM, RAM, and 256K FLASH Memory, which can store up to 1000 fingerprint data. The entire fingerprint comparison process is completed on-chip, with a 1:N comparison within 250 fingerprints, and the result is output within 1 second.

Surrounding the SIB8132 is the input and output module of the fingerprint lock. These modules include power modules, fingerprint capture heads, keyboards, buzzers, and lock drive devices. LCD/LED display equipment, communication interface and debugging interface are optional modules, which can be selected according to product functional specifications.

Specific design points

Lock operation process design

For products such as locks that are used by ordinary people every day, a “simple and practical” operation process is very important. The design of the operation flow is based on the principle of “the simplest” and “the most logical”. Attention should be paid to the design of the lock operation process:

·The sub-function settings are as independent as possible to reduce button reuse.

·The number of keystrokes during operation should be as few as possible, and the operation level should not exceed 2.

Fingerprint operation process design

After the fingerprint function is added to the ordinary lock, the use of the lock objectively brings a certain degree of complexity. Of course, this is only reflected in the fingerprint registration operation during the first use, and the fingerprint unlock operation is still very simple.

When using the fingerprint lock for the first time, you need to store the fingerprint data in the lock control module first. Storing fingerprints needs to go through “fingerprint collection” and “fingerprint discrimination”. “Fingerprint collection” needs to design a friendly operation sequence to guide users to collect fingerprints smoothly. In the “fingerprint identification”, feedback information needs to be given based on the “fingerprint quality” to prompt and help the user to input a better quality fingerprint. The stored fingerprint data is usually called a fingerprint template, and the quality of the fingerprint template directly affects the accuracy of subsequent fingerprint recognition (unlocking).

The fingerprint lock used in most scenarios involves the issue of “fingerprint management”. That is, a specific administrator authorizes others to use the fingerprint lock. “Fingerprint management” includes fingerprint addition, fingerprint deletion (single), fingerprint removal (all). It even includes the management of fingerprint numbers and the identification of duplicate registrations.

In fingerprint locks with higher security requirements, “two-finger (multi-finger) argumentation” may be involved—that is, the situation where the lock can be unlocked only after multiple people’s fingerprint serial verification is passed. These requirements related to the “fingerprint management” function need to be combined with specific application scenarios to complete the process design.

Core control module design

The core control module of the fingerprint lock is a control board designed with SIB8132 as the core. Figure 2 shows the front and back of the fingerprint control board. SIB8132 is a 32-bit high-performance processor similar to ARM7. The working voltage is 3.3V, the core working voltage is 2.5V, and the maximum working current is 75mA. 256K of RAM and ROM make it more than enough to write an application program that integrates password, remote control, and fingerprint. There are two sizes of 14×14mm and 10×10mm. The 100 PIN pins include 3 sets of UART, 32-bit GPIO, primary and secondary I2C, 8-bit parallel port, SPI and other rich interfaces. These interfaces are convenient for the processor to connect with more peripherals, so as to realize a more powerful fingerprint lock system. Therefore, SIB8132 has a greater competitive advantage for the “multi-plate splicing” fingerprint lock solution on the market. Using the SIB8132 processor, it can truly achieve a “single-board single-core” control module.

Fingerprint collection equipment selection

Fingerprint collection equipment is the most important peripheral besides the core control module. Its performance is related to the quality of the entire fingerprint lock. Fingerprint collection equipment is the component that users touch the most, and it is the source of fingerprint data generation. Because it is contacted most frequently, durability and ease of use are the first considerations when selecting a model. Durability considerations are shown in the anti-static ability, wear resistance and corrosion resistance when the finger touches, and whether the sensing sensitivity decreases significantly with the number of uses. It is generally believed that optical fingerprint pickup heads are more durable, while fingerprint pickup heads that use semiconductor direct sensing are more sensitive. Ease of use is reflected in the user’s feelings. Generally speaking, a push-type or planar fingerprint collector is simple to use, and fingerprints can be collected with one touch of a finger. The size of the push type is generally 15mm-25mm square. In addition, in order to reduce costs, and to meet the needs of small handheld devices, many of these products use sliding or scratch sensors, the size of which is only about 10×5mm square.

Of course, for fingerprint locks, users are more popular. Therefore, more press-type heads are used. Use an optical push-type fingerprint capture head at a lower cost. A higher-quality semiconductor press-type fingerprint capture chip (including semiconductor capacitors, semiconductor inductors, and semiconductor pressure sensors are commonly used sensing methods).

Power module design

The power module is very important to any embedded system, and the fingerprint lock is no exception. For fingerprint lock products that use batteries, power supply design, power consumption, and emergency situations such as power shortage must be considered in particular. Choose SIB8132, can reach the working power consumption not to exceed 75mA.

In power supply design, the issue of low-voltage alarms must also be considered. The low voltage alarm is a function that reminds the user to replace a new battery in advance when the battery power is low. In the design, it is necessary to ensure that the available number of times reaches at least 100 times under the low voltage state. If the user still fails to replace a sufficient battery before the power is exhausted, the external power interface needs to be locked to ensure that the door can be opened in an emergency. Of course, the emergency situation also includes the failure of the circuit system. At this time, the “dual machine” mode can be considered, and its safety is higher.

Input and output equipment selection

The input and output devices are selected according to the product function design. It should be noted that if the function is more complicated, a supporting LCD or LED digital tube is necessary. At least in fingerprint management, it is used to display information such as fingerprint numbers.

Design experience sharing

Realize dual-mode work

“Dual-mode operation” means that the fingerprint module can be either in the master mode or in the slave mode.

Because the functional design of different products is different, sometimes the fingerprint recognition module only acts as an independent fingerprint recognition function in the entire system, and does not perform the control of business logic. This is called a universal fingerprint module. Sometimes a fingerprint recognition module is needed to complete some business logic control, which is called the master fingerprint module. The general fingerprint module treats the fingerprint module as an independent entity and communicates with the main MCU through a standard data interface (mostly UART). It only completes fingerprint storage and fingerprint verification functions in the entire lock. The master fingerprint module integrates business logic and fingerprint recognition, with more powerful functions and more cost advantages.

As mentioned earlier, SIB8132 can be used not only as the master control module of the fingerprint lock, but also as the slave module of the fingerprint lock. SIB8132 is currently the only fingerprint dedicated chip that can achieve these two working modes. The reason why this “dual-mode work” can be realized is due to a technical architecture called PLUGIN inside the SIB8132.

Single chip advantage

The traditional fingerprint lock control board mostly uses ordinary DSP to realize the fingerprint identification function. In this way, storing fingerprints requires external memory chips. And DSP can’t be reprogrammed, it can only be controlled through the interface, so a master MCU is needed. As for the SIB8132, one is that the fingerprint is stored in the chip without external expansion storage. The second is that SIB8132 is programmable, can be built-in applications, and can be connected to many peripherals, so it is possible to save an MCU.

This single-chip fingerprint lock application solution saves the cost of the device while also reducing the size of the PCB board, leaving more space for product ID design.

Flexible compatibility

“Flexible compatibility” means that the forward compatibility of fingerprint sensor devices can be realized by changing the built-in program of SIB8132, and even two fingerprint sensor devices can be connected at the same time. The fingerprint sensor market is constantly innovating, and product performance will continue to improve with the improvement of sensing technology. The current fingerprint module and fingerprint sensor are bound one by one. Therefore, as a fingerprint lock product manufacturer, the cost of replacing the fingerprint sensor is equivalent to the cost of replacing the entire fingerprint module. The fingerprint module using SIB8132 is flexible and forward-looking for fingerprint sensor chip access. The replacement of the sensor does not need to replace the fingerprint module, only the firmware can be modified to achieve compatibility with the new sensor.

Concluding remarks

The fingerprint lock market has gradually become the main battlefield for fingerprint applications. It is hoped that the content in this article can provide a certain amount of enlightenment for readers to recognize fingerprint lock products and technologies. At the same time, I hereby declare that the copyright of this article belongs to Mr. Yang Ruobing, and no individual or organization can reprint it without written consent. Please quote the source.

[ad_2]