AWS Smart Weighing System Solution

[ad_1]

1 Overview

The power plant will have transportation fuel and other vehicles coming in and out every day. There are two main modes of transportation: railway transportation and road transportation. This scheme is mainly based on the automatic weighing system of truck scale.

It is said that the cost of fuel for power plants accounts for almost 60% of the cost of the entire plant. The quality of the management of these vehicles directly affects the production efficiency and economic benefits of the manufacturers.

The traditional management mode of fuel delivery vehicles is: when the vehicle arrives at the power plant, it needs to stop and register, after the registration is completed, it is weighed, and then the data is manually input into the computer, and then the measurement is performed. The whole process is time-consuming and burdens the operators. The work intensity of the vehicle, the number of times the vehicle is over-balanced, the vehicle number information of the weighing vehicle, and the weighing time, etc., are manually or keyboard input, and there are the following phenomena:

1. The collection of information relies on manual input, and the input of digital symbols is prone to errors, and it is difficult to achieve real-time and accurate information;

2. The over-balance speed is slow, and the vehicle will queue up and over-balance when the vehicle is over-balanced peak;

3. Some errors are even caused by man-made. For example, after the vehicle is weighed on the truck scale, the driver does not go to the unloading yard to unload the fuel, but replaces the license plate of the vehicle and overbalances the vehicle twice. In this way, sending one vehicle of fuel becomes sending two. Vehicle fuel has caused a lot of economic losses for the power plant. It is said that the cost of the Shandong No. 1 Power Plant is as high as millions of dollars every year;

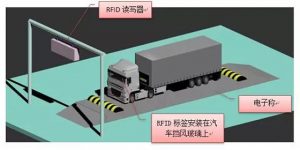

In order to eliminate errors, improve management level, and increase efficiency, Goldu-2000 RFID long-distance wireless identification equipment is installed in the power plant truck scale weighing system, and electronic tags with 16-digit codes are installed on incoming and outgoing vehicles. The fixed information in the electronic tag is unique in the world and cannot be copied or changed. When the vehicle equipped with this card is weighed, the reader will automatically read the tag ID code and send it to the host in real time to accurately record the ID number and vehicle information of each vehicle , Passing time and weight.

The AWS (Auto Weighing System) vehicle intelligent weighing system is a cooperation between Shenzhen Guoyu Information Technology Co., Ltd. and integrators (weighing instrument manufacturers, system integrators, etc.) to integrate electronic vehicle scales, GU990A readers, automatic barriers, Signal lights, cameras, display screens, infrared meters, etc. are integrated into an intelligent system, which automatically records the license plate numbers, weight information, time information, etc. of incoming and outgoing vehicles, and writes them into the host database. The host can transmit data to the monitoring computer in real time, and the monitoring computer can call the data in the host database. Among them, the Goldu-2000 reader and its reading and writing software and testing software are provided by Shenzhen Information Technology Co., Ltd., and the electronic truck scale and intelligent weighing software are provided by the weighing instrument manufacturer (or system integrator).

2. AWS intelligent weighing system design

2.1 System characteristics

The intelligent weighing system uses microwave radio frequency identification technology, electronic truck scale technology, communication technology, automatic control technology, database technology, and computer network technology.

The microwave radio frequency identification technology adopted by Shenzhen Guoyu Information Technology Co., Ltd. has the characteristics of high frequency, good directionality and low electromagnetic interference. Using the principle of radar, the reader sends an inquiry signal to the electronic tag through the antenna. After the electronic tag receives the microwave signal, it answers the inquiry and sends out an echo signal with vehicle information.

Goldu-2000 automatic identification system has the following advantages:

1. Good real-time performance: Goldu-2000 automatic identification system has fast reading speed, and the reading time of label information is less than 0.01 second.

2. High accuracy: The reading accuracy of the Goldu-2000 automatic identification system is higher than 99.99%.

3. Good anti-counterfeiting: The electronic label has a globally unique ID number, which cannot be copied or changed.

4. Simple maintenance: The electronic tag adopts passive technology, no maintenance, long service life (10 years), and low cost.

Goldu-2000 automatic identification system can be widely used in customs vehicle supervision, expressway non-stop toll collection system, urban motor vehicle intelligent management, community parking lot management, intelligent weighing management and other occasions.

2.3 Design principles

As an important subsystem of fuel management in the MIS system of power plants, the intelligent weighing system adopts a variety of strict supervision methods to provide advanced technical means for power plants to strengthen the scientific management of fuel transportation vehicles. The fuel management system provides real-time and accurate basic information. The following principles are mainly followed in the design of the entire system:

Advancement: The intelligent weighing system integrates the application of multiple technologies. The design of this system must take into account the current practical needs and long-term development, that is, to ensure the advanced nature of the technology to ensure that the system will not Outdated to ensure the interests of investors.

Reliability: The entire intelligent weighing system runs 24 hours a day. If the system fails, it will have a greater impact on the production of the enterprise. Therefore, the reliability of the software and hardware must be high. The equipment used in the entire intelligent weighing system is a product with advanced technology and mature application to ensure the reliable operation of the entire system.

Economical: Taking into account the owner’s investment and ensuring the technological advancement and reliability of the intelligent weighing system, we try to select the most economical solution to ensure the owner’s interests.

Practicability: The intelligent weighing system ultimately serves the production of the enterprise and creates benefits for the enterprise. The intelligent weighing system fully considers the convenience of use on the premise of meeting the needs of users, and the selected products have the characteristics of advanced technology, mature, rich software support, and multiple development tools. The hardware installation and debugging are simple, and the user interface is intuitive, rich and friendly.

Security: The intelligent weighing system provides access control functions at the network level, system level, and database level to check whether users have legal identities and permissions, prevent illegal user intrusion and unsafe use of data, and ensure that it is reasonable on the system Data security.

Scalability: The intelligent weighing system has room for future system maintenance and upgrades, and functional expansion. Second, each unit has relative independence, and local modifications and expansions will not affect the overall situation. The network system topology is flexible, adaptable and easy to expand. The application software modules are relatively independent, and the control program is separated from the execution program. It has a high degree of program independence and data independence, which minimizes the impact of changes in institutions and businesses, and facilitates modification and expansion.

2.4 Schematic diagram of intelligent weighing system

2.5 System workflow

1. The green light is on, and the weighing vehicle enters the lane. After the vehicle enters the lane, the red light is on, and the next vehicle is prohibited from entering the lane.

2. The vehicle passes through the entrance induction coil 1 to generate an induction signal. After the reader reads the card, the card information is uploaded to the host database and the vehicle information is retrieved at the same time.

3. The vehicle is weighed on a scale, and the display screen displays the weight information of the weighing, and at the same time captures the image information.

4. After the weighing is completed, the vehicle will pass through the ground-sensing coil at 2 o’clock and lift the gate.

5. After the vehicle is released, the green light will be on at the same time when the gate is off, allowing the next vehicle to enter.

3. Features of AWS Smart Weighing System

3.1 The speed of information collection is fast. The whole system can realize rapid weighing, which improves the efficiency of weighing and avoids the phenomenon of overbalance in queuing.

3.2 Convenient for owners and users: When the driver is overweighting, he does not need to stop and then come down to submit the bill as before, and the operator in the weighing room does not need to input information into the computer. This saves valuable time for both parties and reduces It is inconvenient for the driver to get off the car and the weighing officer to manually input the information.

3.3 Plug the loopholes in human operation. Due to the method of automatically reading data, all over-balanced vehicles are automatically counted by the computer, eliminating manual intervention, automatically recording data, and automatically verifying and releasing.

3.4 High security. Because the electronic tag in the microwave automatic identification system provides the world’s only unchangeable ID number, this fundamentally eliminates the phenomenon of copying, forgery, and cheating.

3.5 Long use time: The electronic label adopts passive technology, does not need maintenance, has a long service life, and can be used for 10 years without damage.

[ad_2]