An Airport Integrated Baggage Handling System Solution Based on the Internet of Things

[ad_1]

In airport integrated baggage handling, baggage sorting, positioning, tracking, and monitoring play a vital role in the entire airport integrated baggage management chain. If the correct sorting and positioning control and tracking cannot be guaranteed, it will directly lead to management The increase in costs makes it difficult to guarantee the quality of services, which affects the competitiveness of enterprises. The traditional way of baggage separation is that when passengers check their baggage before boarding, the baggage will be put on the conveyor belt and transported to the plane on which they are flying. This mode is to use the barcode affixed to the luggage for identification. However, it is difficult to improve the recognition accuracy of the barcode. The position of the handle of each bag is different, and the barcode cannot always face the same direction. Therefore, it is necessary to install multiple barcode readers in several directions. Even so, there are some Phenomenon that cannot be correctly identified. For example, the barcode recognition accuracy rate of the Hong Kong International Airport is 80%, which means that one out of five cannot be correctly identified, which leads to the misdelivery, delay, and loss of luggage at a rate of about 20%. It is necessary to deal with these disputes. It costs a lot of money and brings great losses to airlines. Nowadays, RFID tags embedded in tags, especially Gen2 tags that can be read from a long distance, will greatly increase the recognition rate, and compared to barcodes, Gen2 tags can be posted anywhere. After the Hong Kong International Airport uses RFID tags, the recognition rate has risen to 97%. Compared with previous barcodes, the recognition failure rate has dropped from 20% to 3%.

In large airports at home and abroad, although RFID electronic tag technology is currently used to sort baggage, these systems are only for baggage sorting, and they do not link the baggage information with the powerful Internet of Things well, and are not applied to Mobile phones or wireless PDAs can locate and query baggage information anytime and anywhere, which limits the use of this type of baggage sorting system. By studying the airport integrated baggage handling scheme based on the Internet of Things, this paper has made certain improvements to the original airport integrated baggage handling scheme, and applied it in actual projects, and achieved good results.

1 The Internet of Things and its working principle

1.1 Definition of the Internet of Things

The definition of Internet of Things is: through radio frequency identification (RFID), infrared sensors, global positioning systems, laser scanners and other information sensing equipment, according to the agreed agreement, any item is connected to the Internet for information exchange and Communication to realize intelligent identification, positioning, tracking, monitoring and management of a network.

1.2 Application of the Internet of Things at home and abroad

At present, the United States, the European Union, Japan and other countries attach great importance to the development of the Internet of Things, and have done a lot of research, development and application work. For example, the United States regards it as a magic weapon to revive the economy and attaches great importance to the development of the Internet of Things and the Internet. The core of the Internet of Things is to use information and communication technology to change the future industrial development model and structure of the United States (finance, manufacturing, consumption, and services, etc.), and to change the way the government, enterprises, and people interact to improve efficiency, flexibility, and response speed. Embed sensors in every corner of the world, such as power grids, transportation (railroads, highways, urban traffic) and other related objects, and use the large amount of data collected by the network and equipment to make analysis through cloud computing, data warehouse and artificial intelligence technology Provide solutions to give human wisdom to everything and the earth. They proposed “Smart Earth, Internet of Things, and Cloud Computing” as a proof of the leadership of a new round of IT technology revolution.

my country is not lagging behind in the start-up and development of the Internet of Things. my country’s mid- and long-term plan “New Generation Broadband Mobile Wireless Communication Network” has a key special research and development “sensor and its network”. Many cities and provinces in China have A large number of sensor networks are used to solve information and communication technology services such as “M2M” in electric power, transportation, public security, agriculture and fishery. In the future, the Internet of Things will not only penetrate into the fields of smart transportation, smart cities, environmental protection, government work, public safety, smart homes, etc., it will also greatly promote economic development and be regarded as a strategic emerging industry and a new economic growth point. At present, the Internet of Things has risen to the height of the national strategy, and all cities want to seize this new economic growth point.

1.3 The workflow of the Internet of Things

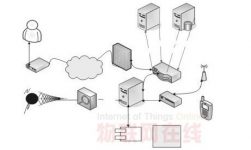

The basic workflow of the Internet of Things consists of four parts, namely the information collection system (RFID system), PML (physicalmarkuplanguage, entity description language) information server, product name server (objectnameservice, ONS) and application management system. The system structure of the Internet of Things is shown in Figure 1.

Figure 1 Structure diagram of the Internet of Things system

Their functions are as follows:

a) Information collection system.

The system includes RFID electronic tags, readers, and data exchange and management system software. It mainly completes product identification and the collection and processing of product EPC (electronic productcode) codes.

The EPC code of the product will be automatically captured by the detector when the electronic tag storing the EPC code passes through the reading and writing sensing area, thereby realizing automatic EPC information collection; then the collected information is processed and processed by the server connected to the detector The device is installed with information collection and processing software, which further processes the collected information, such as data analysis, filtering, integrity check, etc. The processed data is saved in the corresponding database for the upper-level application management software use.

b) Product Naming Server (ONS).

The main function of the server ONS is to establish an association between each information collection point and the PML information server, and realize the mapping from the EPC code of the electronic tag of the article to the PML description information of the product.

c) PML information server.

The data definition rules in the server are created and maintained by the user. The user encodes the item according to the pre-defined rules, and uses XML to describe the item information in detail. In the Internet of Things, the PML server is mainly used to provide the rule definition of the original information of the item in a general mode, so that it can be accessed by other servers.

d) Business management system.

The system obtains the EPC information obtained by the information collection software, and finds the PML information server of the item through ONS, thereby providing Internet users with functions such as information query and tracking in the form of Web. Users can also learn about items in real time through mobile phones or wireless PDAs. status.

2 Airport integrated baggage handling system design

2.1 System architecture design

The airport integrated baggage handling based on the Internet of Things uses the most advanced radio frequency identification technology in the world. The barcode of each piece of baggage strictly corresponds to the number of the baggage trolley on the conveyor belt. They will automatically identify the baggage, no matter where the baggage goes, as long as Enter the number of the trolley to track and monitor the luggage. In addition, multiple cameras can be installed in the baggage workshop to basically cover all blind areas. The staff can observe the whereabouts of the baggage at any time in the monitoring center. Even if the luggage takes the wrong route, with this identification system, the staff can control the trolley to return it to the correct route, which basically eliminates the situation of missing or taking the wrong luggage.

The structure of the airport integrated baggage handling system based on the Internet of Things is shown in Figure 2. It is mainly composed of five modules: baggage item identification, information processing/baggage control/tracking, PML server, local database server, and business system.

Their functions are as follows:

a) Identification of baggage items.

The core of the system is the coding and identification of baggage.

Since the barcode of each piece of luggage strictly corresponds to the number of the luggage trolley on the conveyor belt, they will automatically identify the luggage, no matter where the luggage goes, just enter the trolley number to track and monitor the luggage. Therefore, in the RFID tag-based airport baggage management system, the EPC code is used as the unique identification code of the baggage. The tag is composed of a chip and an antenna (antenna), and each tag has a unique product electronic code. The EPC code (electronic productcode) is the only searchable identification code assigned by the Auto-ID Research Center for each physical object. It contains a string of numbers that can represent the baggage category and passenger ID, boarding date and boarding place, valid Information such as the date and where it should be shipped. At the same time, these data can be updated in real time as the baggage is transferred or changed in the airport. Generally, the EPC code can be stored in an electronic tag made of silicon chips and attached to the marked luggage to be recognized, transmitted and inquired by the information processing software.

b) Information processing/baggage control/tracking.

This module is the core functional module of the system. It interacts with other functional modules through three interfaces: data collection interface, information processing, baggage tracking and monitoring, so as to realize the automatic processing of airport baggage.

The information processing/baggage control/tracking business processing logic is shown in Figure 3. When the baggage passes through the baggage entrance, the EPC code of the baggage is read by the baggage tag detector installed at the baggage entrance, and then passed to the baggage information processing module through the data collection interface. Multiple baggage tags and barcode information can be installed at the airport baggage entrance for sorting Some of them are used for domestic flights and the others are used for international flights. The baggage sorter also provides a manual coding area for unreadable tags. For example, the baggage sorter system of Shanghai Pudong Airport, whether it is an international flight or a domestic flight, arriving in Shanghai or transiting in Shanghai, can easily sort the baggage. The system also provides an early baggage sorting function. The checked baggage is delivered to a suitable location through a rotary conveyor, so that it can be stored in an orderly manner before the plane takes off.

c) PML server.

This server is mainly a passenger information server created and maintained by airlines. It is based on standard XML and provides detailed baggage information, such as baggage category and passenger ID, boarding date and boarding place, valid date, and destination Location and other information, and allow the baggage information to be inquired through the EPC code of the baggage. The PML service architecture is on a Web server. The service processing program converts the baggage data in the data storage unit into a standard XML format, and provides services to the client through the SOAP engine. The PML server shields the heterogeneity of data storage. The unified format provides information services to the interface requester. The working principle of the PML server is shown in Figure 4.

d) Local database server.

The server is mainly used to store the baggage information obtained by the data collection and processing interface for query and maintenance in the business system.

For example, the user can check the current status of the luggage anytime and anywhere through a mobile phone or a wireless PDA or Web client.

The airport baggage integrated processing system based on the Internet of Things mainly realizes the automatic identification and delivery of luggage through RFID electronic tags, uses the Internet of Things to obtain the original information of passengers and automatically generates passenger luggage lists, thereby greatly improving the automated sorting and intelligence of airport luggage化 level.

2.2 System development platform

The system uses the Internet environment and adopts the B/S model for development. The server-side operating system of the system is WindowsServer2008, the development tool is Eclipse, the main technology is JavaEE and Java language programming, the database system is Oracle11g, and the sorter uses FKILogistexS-3000E turntable sorter. In this system, one set is used for domestic flights and two sets are used for international flights.

Another important feature of the S-3000E Tumbler Sorter is that it provides a manual coding area for handling unreadable labels. The FKILogistex system has extremely strong processing capacity and extremely high flexibility, so whether it is an international flight or a domestic flight, arriving in Shanghai or transiting in Shanghai, baggage sorting can be carried out easily.

3 Implementation of the airport integrated baggage handling system

3.1 The key technology of system realization

In the airport integrated baggage handling system, each participant in the baggage chain is a key point of the handling system. Once there is a problem with the product, whether the specific source of the problem can be found and the correct implementation of baggage recovery depends on whether the participant’s record is sound.

To ensure the integrity of the airport’s integrated baggage handling, each participant in the baggage chain is uniquely coded. The code consists of 2 baggage category codes and 18 passenger ID codes, 10 boarding date codes and 3 boarding place codes, 3 destination codes and 4 serial numbers. Before passengers board and check their luggage, a RFID card is affixed to each passenger’s luggage, and each RFID card corresponds to one passenger’s luggage. The RFID card can quickly and accurately provide the automatic identification function for the baggage sorter, and the operation is quick and convenient. At the same time, even if the RFID card is partially worn out in the harsh environment of the airport, it will not affect the identification effect of the sorter. The RFID electronic tag coding composition is shown in Figure 5.

3.2 Design of RFID reader service component

In this system, the remote method call of each reader module is encapsulated as a management component (MBean) as an instance of the JMX server and registered in the JMX server. JMX (Java management extensions, Java management extensions) is a framework for implanting management functions for applications, devices, systems, etc. In the JMX specification, a management component is a Java object that can represent a management resource, and it follows a certain design pattern to implement a specific interface defined by the specification. This definition ensures that all management components represent managed resources in a standard way. The management interface is some information exposed by the managed resource, and the managed resource can be controlled by modifying this information. The management interface includes the attribute values that can be touched, the operations that can be performed, and the notification events that can be sent.

The reader is monitored and managed through the JMX framework, so that the RFID middleware system can provide the functions of management and monitoring of the reader. The JMX time service triggers the message on the specified date and time, or it can trigger the message repeatedly at a fixed interval. The time service is implemented by an MBean and can be managed. It can send a message instance of the timerNotification class it specifies, and the interface javax provided by Java.

The management.NotificationListener is implemented by the object that wants to receive notifications and implements the method handleNotification. For periodic notifications, a fixed delay execution scheme is used, as specified in the timer. In order to use a fixed-rate execution plan, the addNotification method is used.

{$page$}

3.3 Design of RFID middleware

According to the previously studied label ID representation method and the definition of savant middleware, the functional modules of RFID middleware should include the following functional modules:

Reader interface module, logical drive mapping module, RFID data filtering module, business rule filtering module, device management and configuration module, upper-layer service interface module, as shown in Figure 6. Among them: the reader interface is used for data communication between middleware and RFID readers, mainly to obtain RFID data and issue reader instructions to the device management module; the device management configuration module is used to adjust the working status of RFID readers and configure accordingly The reader interface parameters, etc.; the logical reader/writer mapping module is used to map multiple physical readers or multiple antennas of the reader into a logical reader. A logical reader/writer represents a data collection point with specific meaning (such as Airport Terminal 1), regardless of how many readers and antennas the collection point is physically composed of. It shields the specific implementation of data collection points, and reduces the degree of software coupling between upper-level modules such as data filtering and lower-level data collection parts. For the upper module, only the logical reader/writer is visible, so the logical reader/writer mapping module has a preliminary filtering function for RFID data.

3.4 Design of RFID data collection and filtering method

The amount of raw data collected by RFID is very large. In practical applications, depending on the specific configuration, each reader can report several to dozens of electronic tag data per second, such as scanning the same electronic tag multiple times. Tags, but only a small part of them is meaningful and non-repetitive data for users. If such a large amount of data is uploaded directly without redundant processing, it will bring a great burden to the entire RFID system. Therefore, the data collected by RFID is filtered.

The design of RFID data collection and filtering methods is mainly divided into the following categories:

a) Establish a data collection event list class.

Perform real-time detection of each new electronic tag data. If it is a newly scanned electronic tag, it will be added to the corresponding list; if the tag already exists in the list, only the time and other status data of the corresponding tag will be updated without creating a new one Label data records to achieve the purpose of eliminating duplicate data.

b) Data collection event coding category.

Encode the status change of the electronic tag, define the status code of the tag appearing as 0, and the code disappearing of the tag status as 1, and then add the timer mechanism to ignore the status transition of the same tag within the valid time of the timer, so as to State definition and time dimension deduplicate data.

The above-mentioned algorithms can eliminate redundant data well and reduce the load of the upper system. However, in practical applications, in addition to the de-redundancy of RFID data, there are other requirements for data filtering. For example, due to unstable signals or other interference factors, the RFID tags on the luggage cannot be detected in every reader cycle; or when the luggage cart passes by the shelf, the existing items in the luggage cart are taken by the airport. The reader in the entrance misread it. In response to the above problems, adaptive and effective filtering algorithms are designed in different application scenarios. The experiment platform uses a single-antenna reader with RS-232 interface. The reader’s reporting period is 1s, and the number of tags reported each time is five. The algorithm is implemented in Java language, and serial communication is carried out through the Java serial port.

The first is to build a RTagReadEvent class for tags. The key parameters and methods included in this class are as follows:

When the main program of the filter module detects a new tag, it creates an object newReadTag of the RTagReadEvent class, assigns initial values to each key field, and starts the timer thread inside the object: newThread (newRead-Tag). start(). The function of the timer thread is to check the tag weight value and trigger the corresponding operation every reporting period. After each check, the tag weight currrentvalue is reduced by 1 to achieve a gradual decrease in the weight of the tag when it is not reported. When the weight currentvalue decreases to 0, the timer thread stops and the object can be destroyed at this time.

When the main module of the filtering algorithm finds that the reported label already exists, it accumulates the currentvalue value of the label object:

Among them, valueStep is the cumulative weighted value defined in the algorithm. If the weight currentvalue has reached the threshold readTagmax, keep it at this value to prevent the tag weight from being too high after multiple reporting cycles, which will affect subsequent judgments.

3.5 RFID data collection simulation and implementation

The algorithm is used to simulate the luggage rack with reader at the airport. When the luggage rack reader can stably identify the loaded luggage with tags, it will not misreport the departure information of the goods due to signal fluctuations, and it will not Other items on the shelf maintain low sensitivity. In this application scenario, set valueStep=5, tagmax=8, and tagmin=0. When the tag enters the reader’s range, after about 8s, the filter module triggers the tag appearing operation. The tag is manually moved out of the reader’s range for a short period of time to simulate signal interference and fluctuations, and another tag is read and written from After moving within the range of the reader, the reader does not trigger the appearance and disappearance of redundant tags. The reader scans the tag data as shown in Figure 7.

Mark the RFID tag code that appears in the cycle of Figure 7 as 1, and the code that does not appear as 0. In this way, for each baggage electronic tag, its event can be recorded as a 01-order binary string. For Figure 6, tag1 can be coded as 010010111, which means the tag has passed the range of the reader; tag2 can be coded as 11011000, which means the tag has left the range of the reader; tag3 can be coded as 00000011, which means the tag enters and stays in the read/write range In the scope of the device.

3.6 Realization of business system

Based on the above-mentioned basic principles, this paper designs and implements an airport integrated baggage handling system based on the Internet of Things based on the JavaEE platform. The prototype system realizes the information collection system baggage item identification, information processing/baggage control/tracking, and maintenance of the PML server , Maintenance of local database, etc. The airport baggage integrated processing system based on the Internet of Things mainly uses RFID electronic tags to realize the automatic identification and delivery of baggage, and uses the Internet of Things to obtain the original information of passengers and automatically generate the passenger baggage list. Among them, the business management system obtains the EPC information obtained by the information collection software, and finds the PML information server of the item through ONS, and provides Internet users with the management interface of functions such as information query and tracking in the form of Web, as shown in Figure 8. The interface for the user to know the status of the item in real time through a mobile phone or a wireless PDA is shown in Figure 9.

Usually, passengers have to check in large pieces of luggage when taking an airplane. However, due to various reasons, sometimes it is inevitable that individual luggage cannot follow the passenger’s flight to the destination.

Passengers who cannot find their checked baggage after disembarking the plane will report the situation to the baggage inquiry department located in the baggage arrival hall, and the baggage inquiry staff will record the relevant situation. In the past, if passengers wanted to know the status of their baggage search, they could only find out the situation by dialing the airline’s phone number. Not only was it difficult to make the call sometimes, but they also didn’t understand the explanation of the staff. Through this system, passengers only need to log in to the airport integrated baggage handling system of the Internet of Things via their mobile phones or the Internet to enter relevant information, and then they can see the latest progress of their lost baggage. If it has been found, it has been delivered to the passenger or is inquiring middle. At the same time, passengers can also see the specific work processes of airline staff, such as which terminals have telegrams sent to and where they have been searched, etc. This not only satisfies passengers’ right to know, but also allows passengers to monitor the airline at any time. work.

4 summary

In the airport integrated baggage handling, the most critical issue is the identification/monitoring of baggage and the acquisition/inquiry of baggage information. Aiming at the problems of traditional airport baggage handling, this article combines electronic tags with the Internet of Things, uses electronic tags as a means of baggage identification, and uses the Internet of Things to monitor and obtain information about baggage items, and proposes an airport integrated baggage handling based on the Internet of Things The structure and function of the system are analyzed in detail, and the advantages and feasibility of the system are explained through application examples. The airport integrated baggage handling system based on the Internet of Things proposed in this paper is highly automated. At present, the airport integrated baggage handling system developed based on this program has been installed and used in some domestic airlines, and will continue to be improved based on user feedback in the future.

[ad_2]