Telecom industry RFID asset management system solution

[ad_1]

I. Introduction

Asset management currently relies on traditional manual management methods and means. Data collection and entry have always been manual operations, which are inefficient and high in error rates, and asset physical information and management system information cannot be synchronized in real time. As a bridge between the physical world and existing IT systems, RFID technology uses GPRS wireless transmission technology to effectively integrate daily asset management activities with asset management systems, so as to achieve real-time synchronization of physical information and system information.The goal of this implementation is to useRFIDHandsets, electronic tags and personnel management cards can automatically track materials, equipment and valuable supporting items in real time, focusing on “asset life cycle management” and “simultaneous management of people, place, time and things”.

2. Demand analysis

According to the needs of customers, after analysis, it can be summarized into 2 categories:

(1) Technical requirements: Make full use of advanced RFID technology to achieve contactless, real-time, accurate, complete and fast data collection.

(2) Management requirements: Realize timely, effective and accurate management of base station communication equipment through RFID data collection. The system plan is divided into three parts: the acquisition layer, the transmission layer and the execution presentation layer.

Acquisition layer: equipment including: RFID handheld,electronic label.

Transmission layer: The transmission layer equipment includes GPRS network and GPRS communication module. The GPRS module is extended by the handheld device to communicate with the asset management center server. The data collected by the handheld device is transmitted to the executive presentation layer through the GPRS network. At the same time, it can also Download the equipment classification information of the base station from the server for asset inventory.

Executive presentation layer: Process the base station and its equipment information transmitted from the collection layer, record and control the working mode of the front-end collection layer.

Three, system overview

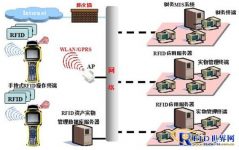

The RFID automatic identification system is responsible for the automatic collection of operator information, asset changes, and inventory information, and uploads the information to the management center asset management auxiliary system server in real time through the GPRS communication module extended by the RFID handset, as an update database and other MIS, EMIP, etc. The data source of the system application, the system is embedded in the GIS system, through the visual query/statistic interface, to provide users with multi-angle/dimension query statistical data. The system informs implementers such as asset allocation and related management personnel by means of SMS through the SMS module, so that the administrators can grasp the status of asset allocation and work order completion in time, realize effective supervision of daily management work, and improve work efficiency.

Fourth, the overall structure

This system uses advanced radio frequency identification technology (RFID), modern computer technology, GPRS wireless remote communication technology, automatic control technology and other technologies to comprehensively realize automatic asset identification, informatization and intelligent management.

Work flow: Asset management includes operations such as adding assets, allocating, warehousing, and inventory. It includes the entire process of equipment from purchasing and putting into use to scrapping out of use. The specific work is shown in the figure above.

Working principle: Each asset is attached with an electronic tag with a unique ID number. When the asset enters the identification area of the RFID handset antenna, the antenna activates the electronic tag circuit by sending a microwave signal, and at the same time, the electronic tag sends an echo signal. Two-way data exchange, the reader obtains relevant information, and at the same time uploads the asset-related information to the RFID system server in real time, performs corresponding format conversion, filtering and related follow-up statistical processing, as other systems to achieve relevant data statistics, query and other functions The data source realizes real-time monitoring, recording and automatic update of change information in the daily management of assets.

Five, system advantages

The system has highly confidential asset files, strengthens equipment supervision through high-tech, rationally allocates resources, reduces resource waste, and prevents asset loss.

Automatic real-time collection of equipment information, which can be transmitted to the server background processing in real time through the GPRS network, without manual intervention, automatically generates asset allocation, inventory and other operation records, flexibly and automatically outputs various query statistical reports according to the selection conditions, and can be exported as an Excel table, Therefore, a series of problems such as data distortion caused by human factors in the process of manually collecting and entering asset information are avoided, and the quality of basic data is guaranteed through automated management methods, and work efficiency is improved.

The system realizes the full life cycle management of assets from purchase, use, maintenance, scrapping and disposal. Through the comprehensive centralized monitoring and management of assets, it solves many management blind spots in the existing management model, and further improves the utilization rate of assets. Provides data assurance.

The RFID system application only needs to write asset information in the back-end system and electronic tags at a time, and the system automatically records the change information of the asset, which turns the tedious manual recording in the daily asset management into “no manual recording required”, reducing information transmission Links to improve the accuracy and effectiveness of information.

Through intelligent dynamic real-time tracking and centralized monitoring and management of the entire life cycle of assets, it provides accurate reference for the company’s investment decision-making and rational asset allocation, effectively increasing the marginal benefit of investment and improving asset utilization, reducing unnecessary equipment investment and idleness waste.

Realizes the dynamic tracking management of “people, place, time, and things” in the real automatic information collection, reduces the pressure of daily asset management, saves the cost of investing a lot of manpower and material resources for asset inventory and unnecessary allocation every year, and avoids The loss of assets due to various factors has improved the efficiency of corporate management.

The system has the characteristics of long-distance rapid identification, high reliability, high confidentiality, easy operation, and easy expansion. The asset identification system can operate independently and does not depend on other systems. The implementation of this project does not require any changes to the existing equipment of the management site, and does not affect the normal operation of the company’s other businesses.

Realize the real-time consistency between asset change information and system information, and use the SMS alert reminder function to organically integrate daily work with the IT system, and achieve effective real-time monitoring and recording of the work process by the back-end system, so that managers can In the office, you can learn about the allocation and use of assets in a timely manner.

[ad_2]