RFID-based Elevator Maintenance Electronic Supervision System

[ad_1]

I. Overview

The “Elevator Maintenance Electronic Supervision System” is a high-tech means to ensure the implementation of laws and regulations. The daily maintenance, repair and troubleshooting information of the maintenance unit can be collected on the spot and sent to the quality supervision department and the corresponding inspection agency in a timely manner. Through the system network, the inspection agency can comprehensively monitor the safe operation of the elevator and the work development of the maintenance unit. The competent quality supervision department can also synchronize the work process of the supervision inspection agency and the maintenance unit, so that the elevator safety supervision work is timely and efficient.

2. The overall system architecture and function description

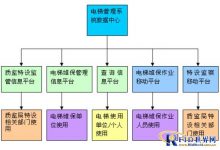

1. System architecture

2. Function description

The system is divided into five platforms. Including Quality Supervision Bureau supervision network platform, maintenance company management platform, public inquiry platform, quality supervision bureau supervision mobile platform (based on PDA) and maintenance personnel maintenance platform (based on PDA). It can be used by three types of users including relevant departments, elevator maintenance units, elevator users/the public, etc. specially set by the Quality Supervision Bureau.

By constructing a comprehensive system, the elevator maintenance unit can instantly query the maintenance status of all elevators in the unit through the electronic supervision system, and can establish elevator maintenance electronic management files. When a certain elevator exceeds the maintenance time, the system can automatically send a reminder message to the mobile phone of the person in charge of the registered unit. The inspectors of the quality supervision department can use the PDA mobile phone to scan the electronic tags to find out whether the elevator maintenance unit performs maintenance according to the specified time interval and project content, and handles violations. After the completion of the maintenance, the elevator maintenance personnel write the maintenance information into the special elevator maintenance electronic tag through the mobile work platform PDA, and upload the information to the data center. The promotion of the elevator maintenance electronic supervision system will strengthen the internal management of the elevator maintenance unit, greatly improve the efficiency of maintenance work, and enhance the effective supervision of the elevator maintenance work by the quality supervision department.

3. Introduction of main RFID equipment

1. RFID mobile working platform

PDA+GPRS+WIFI+RFID integrated industrial design, complete functions, easy to operate, easy to carry, can meet all the hardware and software functional needs of elevator maintenance mobile work platform and quality supervision mobile supervision platform.

2. Special anti-metal interference electronic tags

Original Philips chip PVC package, professional anti-metal interference design, large user storage space, strong self-adhesive installation mode.Mature technology, convenient installation, stable and reliable performance, high safety, and long life. It is a special metal equipment such as elevators.RFIDManage the best electronic label selection.

[ad_2]