UHF RFID clothing supply chain management system

[ad_1]

1. Industry overview

In the traditional concept, the clothing industry is a low-tech labor-intensive industry, but in fact, the development of the entire industry is inseparable from the height of science and technology. From the production of clothing fabrics to clothing design, production and production, logistics to terminal sales, any link is indispensable to the support of scientific and technological strength, especially in supply chain management, faced with inaccurate inventory information, often out of stock and out of stock, goods cannot be Tracking and tracing, often sending wrong goods, asynchronous logistics and information flow, and high labor intensity have brought considerable challenges to the operation and management of garment enterprises.

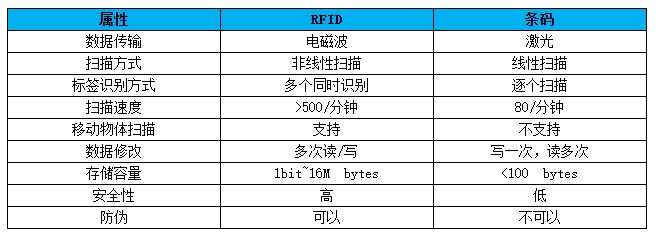

In recent years, many garment enterprises have also realized the importance of scientific and technological power, and began to explore the supply chain management represented by barcode technology. Information level of chain management. However, due to the poor penetration of barcode recognition, it must be sensed within a small distance. The barcode recognition process cannot be read in batches, and there are many misreading situations in the barcode recognition process. This is because barcodes are printed on paper media. easily damaged and destroyed. In addition, the information that the barcode itself can represent is too single, and cannot describe more characteristics of a certain piece of clothing. There is still a lot of room for improvement in the information management of the clothing supply chain.

2. Technology application

UHF RFID technology is a new automatic identification technology that has changed the supply chain management mode of the clothing industry after bar code technology. It uses the principle of radio frequency identification, which can work in various harsh working environments and can penetrate certain The RFID tag can also repeatedly erase and write data, and the tag can be reused. These characteristics determine that it is currently the most suitable industry for the application of RFID technology. In the process of entering and leaving the warehouse and inventory, the clothing is read in batches accurately, which reduces the labor intensity and avoids possible errors in manual operations, bringing a qualitative leap for enterprises in management cost control, rational allocation of resources and comprehensive competitiveness of enterprises.

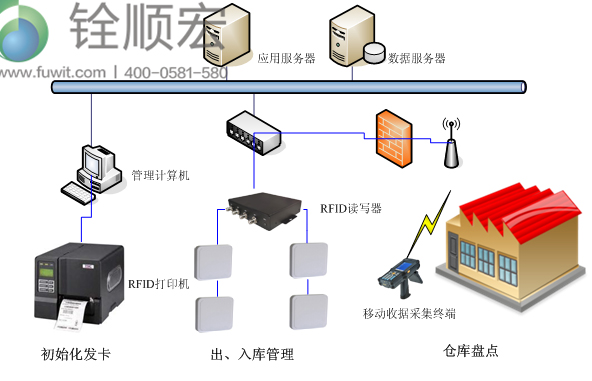

3. System Design

3.1 Precise packing

Labels are the basis of the entire RFID system. Each electronic label needs to be encoded at the front end, and then bound to the clothing to complete the identification of clothing information by the electronic label.

Using the unique identity of RFID tags, sticking, embedding or implanting RFID tags on each piece of clothing can completely solve the problem of unrecognized and tracked clothing when packing, and achieve accurate packing.

3.2 Inventory management

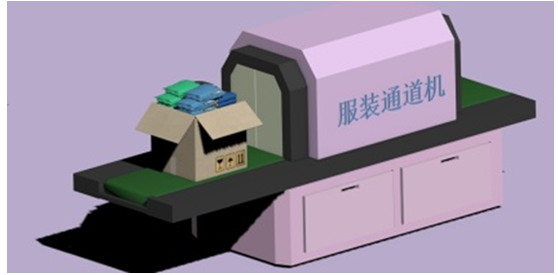

Clothing out of the warehouse is a reverse process. The clothing from the warehouse also passes through the RFID reading platform to complete the acquisition of outbound clothing information in batches, and verify the outbound order to ensure the consistency of logistics and data flow.

The schematic diagram of the RFID reading platform is as follows:

3.3 Warehouse inventory

The traditional method of using barcode or manual inventory one by one has long inventory cycle, heavy workload, heavy tasks, slow speed, low efficiency, error-prone and large error. The application of RFID technology in inventory can give full play to the advantages of long-distance and simultaneous reading of multiple tags.

The operator only needs to download the clothing information to be counted in the background system. After arriving at the warehouse, using the RFID mobile handheld terminal, the system information can be quickly and accurately compared with the actual clothing information collected to complete the inventory task.

3.4 Extended application

RFID can also be used in anti-theft applications in warehouses. Install an RFID reading channel at the door of the warehouse. Any unauthorized apparel products will be identified and alerted by the system when entering or leaving the warehouse.

The application of RFID technology in clothing supply chain management can realize the automation of warehouse management, check the inventory of each warehouse at any time, and track the logistics process of products in time. At the same time, the use of electronic labels can easily achieve the accuracy of the receipt of goods and the automation of delivery and distribution, so that there will be no omission and loss of inventory. Real-time and transparent supply management can provide scientific basis for clothing sales, production and stocking while ensuring the first-in, first-out of clothing.

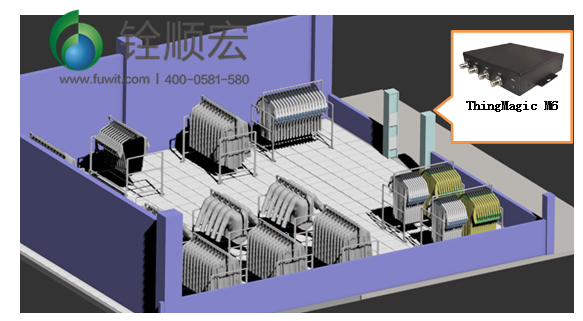

4. Hardware selection

In this system, the speed and accuracy of RFID data collection are very important, and the core equipment is RFID fixed reader and mobile data collection terminal.

4.1 Fixed reader

Quan Shunhong FU-M6-AW is a core integrated with ThingMagic’s excellent M6e-A module.Industrial grade four-channel fixed reader WIFI version. 4-way TNC provided with high-quality sheet metal housingantennaInterface, support 4 independent antennas, provide industrial-specific communication and power interfaces, small appearance, convenient installation. IP56 protection grade is suitable for use in various industrial and commercial environments, and meets the harsh working environment of high and low temperature.

widely adapted tomedical,hotel washing,Smart Warehousing,new retailused in various industrial and commercial environments.

4.2RFIDHandheld

Quan Shunhong W6100 RFID Smart HandheldIt is a portable intelligent data acquisition device based on Android system development, integrating 1D or 2D barcode scanning, 4G full Netcom, GPRS, WIFI, BLUETOOTH, RFID functions; friendly interface, easy operation, integrated ThingMagic high-performance module, with Efficient inventory, remote scanning, accurate reading and other advantages;

adapt toWarehouse Logistics,jewelry store,Archive Booksand other multi-scenario applications.

Features

1) Simple body design, high-definition large-screen display With a simple body design, it is displayed on a Corning Gorilla 5.5-inch IPS high-definition display. The item resolution of 1440*720 and the arc design of the corners take into account the comfortable grip and the drop resistance of the machine itself.

2) Powerful fast charging and WiFi roaming function Equipped with 9000mAh polymer lithium battery optional, long-lasting battery life, and supports fast charging function, the single charging time is shorter. And powerful WiFi roaming function, which can realize seamless switching of WiFi hotspots and maintain an uninterrupted network connection experience.

3) Excellent RFID reading and writing function, multi-tag long-distance reading and writing adopts omnidirectionalhelical antennaWith professional scanning handle and shield, it supports ultra-high frequency single-tag and multi-tag reading, longer distance, faster efficiency, more stable overall performance, and effective reading distance up to 20m.

4.3RFID printer

TXr series RFID Label Printer Equipped with superior design and practical features, enjoy the convenience of a smart printing solution. The design of first printing and then reading and writing, 100% label pass rate, TXr series electronic label printing solution is the guarantee of automatic sorting and work.

It supports reading, writing and printing of electronic labels with a minimum height of 12 mm, and is suitable for flexible anti-metal labels, flexible consumables compatibility, and high-quality print output, taking you into a wider application field.Products are widely used inAutomotive Manufacturing,Apparel Manufacturingfinancial services industry,Logistics and transportation,jewelry storeand other industry segments.

Features

1) Precise positioning of 12mm ultra-small label reading and writing;

2) Read and write labels after printing, 100% label pass rate;

3) Applicable to flexible anti-metal labels, the application field is wide and flexible;

4) One-key positioning of the antenna position is smart, precise and convenient;

5) HEAT intelligent thermal balance control technology, microsecond real-time intelligent control, clear and sharp printing guarantee.

About Quan Shunhong

ShenzhenQuan Shunhong TechnologyAs an RFID service provider, While providing a full range of ThingMagic products to major operators and integrators, the company has also been providing our customers with world-class RFID equipment solutions and high quality with a professional technical team, high-quality service and preferential prices. after-sales service.The company has cooperated with major operators and integrators to successfully apply ThingMagic RFID equipment toexistWarehouse Logistics,file informatization,air shipping,clothingzerosale,carsystemmake,wisdommedicaltreatment,asset Management,Anti-counterfeiting traceabilityvarious applications in many fields. From product selection, to solution design and system platform support, we provide users with comprehensive technical services that are easy to operate, highly stable, differentiated and innovative.

[ad_2]