Application of RFID in the process of product warehousing management

[ad_1]

In the process of product warehousing management, the most important and core problem is the identification of products and the acquisition of warehousing information. Although traditional manual or barcode recognition technology has been applied to a certain extent, the following problems still exist:

1. Difficulty in product identification. Although barcode recognition technology has certain applications, barcode scanners must “see” the barcode to be able to read it. The barcode is easily torn or defaced, which brings certain difficulties to product identification, and the identification distance of the barcode is very short. Simultaneous identification of multiple products, these defects make the application of barcode technology in warehouse management subject to certain restrictions;

2. Product information is difficult to obtain in real time. When the product is put into storage, it is necessary to record the name, classification, specification, manufacturer, quantity, storage time and other information of the put-in product, and generate a storage list for later verification and verification. However, it is often difficult to obtain this information, sometimes requiring the assistance of product suppliers, coordination is difficult, and the real-time information is also poor;

3. The degree of automation of warehousing operation is not high, and manual dependence is strong. When the goods entering the warehouse are of various types and centralized packaging, manual inventory and registration are required, which is far from being able to meet the needs of fast and accurate warehousing. Manual inventory and warehousing are not only a lot of work, but also very complicated and very easy to make mistakes.

On the basis of the computer Internet, the Internet of Things uses electronic tags to give each item a unique identification code-EPC code, thereby constructing a physical Internet that realizes the real-time sharing of global item information. Its proposal provides an effective means to obtain the original product information and automatically generate the warehousing list when the product is put into the warehouse, and the electronic label can conveniently realize the automatic product identification and product information collection. Product storage becomes possible, which will greatly reduce the degree of manual intervention in storage management and improve the automation and intelligence level of product storage.

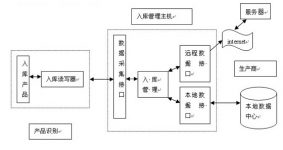

Structure diagram of an automatic warehouse management system based on the Internet of Things

Warehouse warehousing management is to identify the products entering the warehouse, classify, check and register the products, generate a list of warehousing products, and record the name, classification, specifications, warehousing time, manufacturer, production date, quantity and other information of the product , And update this information to the inventory record. These tasks require high accuracy and heavy workload, and the manual work intensity and difficulty are very huge. Therefore, there is an urgent need for technologies and methods that can automatically identify products to reduce the workload of managers and improve work efficiency. The key to warehousing management lies in the identification of products and the collection of product information. With its unique advantages, electronic tags have become the key technology for automatic product identification, and the Internet of Things provides an efficient and fast network platform for product information sharing and intercommunication. . The basic principle of the automatic warehouse management system based on the Internet of Things is to use electronic tags as the technical link for product identification and information collection. The product is automatically identified by setting a reader at the entrance and exit of the warehouse, and the detailed information of the product is obtained through the Internet of Things. Automatically generate the warehousing list to achieve the purpose of automatic warehousing management. The automatic warehousing management system based on the Internet of Things is mainly composed of four functional modules: product identification, warehousing management, PML server and local data center.

1. Product identification. The core of the product identification system is the coding and identification of the product. In the electronic tag-based warehouse management system, the EPC code is used as the unique identification code of the product. The EPC code is a coding specification for electronic tags proposed by the Auto-ID Research Center. It enables all commodities in the world to have a unique identification. The biggest feature is the single product identification. The product identification system includes electronic tags and readers. Each product is attached with an electronic label, and the EPC code is written in the electronic label as the unique code of the product. When the electronic tag with the EPC code passes through the sensing area of the reader, the EPC code will be automatically captured by the reader, so as to realize automatic product identification and EPC information collection. The warehousing reader is set at the entrance of the warehouse to automatically identify the products entering the warehouse, and transmit the captured product EPC code to the warehousing management module through the data collection interface for corresponding processing.

2. Warehouse management. The warehousing management module is the core function module of the system. It interacts with several other function modules through three interfaces: data acquisition interface, remote data interface and local data interface, so as to realize the function of automatic product warehousing management. The work flow of the warehousing management is as follows: When the product is warehousing, the warehousing reader set at the entrance of the warehouse reads the product EPC code and the warehousing management module through the data collection interface, and the warehousing management module accesses the PML through the remote data interface The server obtains the detailed information of the product, and automatically generates the product warehousing list, and then updates the warehousing product information to the local data center through the local data interface. Generally speaking, the warehousing list has the following information structure: the warehousing list (product EPC code, product name, manufacturer, product classification name, unit, production date, validity period, warehousing time, product description), in this information In the structure, the product EPC code is automatically recognized by the warehousing reader and writer, and the product warehousing time is recorded at the same time. Other product information can be obtained by accessing the PML server according to the product EPC code, and the entire warehousing list is generated automatically. Yes, this not only improves the automation level and intelligence level of product warehousing, but also ensures the accuracy of warehousing product information, laying a good foundation for scientific inventory management and decision-making.

3. PML server. PML server is a product information server established and maintained by product manufacturers. It provides detailed product information, such as product name, product classification, manufacturer, production date, product description, etc., based on standard XML. The function of the PML server is to provide detailed product information required to automatically generate a product warehousing list, and to allow product information to be inquired through the product EPC code. The PML server is based on a web server. The service processing program converts the product data in the data storage unit into a standard XML format, and provides services to the client through the SOAP (Simple Object Access Protocol) engine. The advantage of the PML server lies in it The heterogeneity of product data storage is shielded, and transparent product information services are provided to the client in a unified format and interface.

4. Local data center. The local data center is the local database where the warehousing management system stores and maintains the local inventory. The product warehousing information is finally stored in the local data center through the local data interface for query and verification.

The automatic warehousing management system based on the Internet of Things revolves around the two cores of electronic tags and the Internet of Things. It realizes automatic identification of products through electronic tags, uses the Internet of Things to obtain original product information and automatically generates a warehousing list, thereby providing automated warehousing management It provides an effective method that not only greatly improves the automation and intelligence level of product storage management, but also makes storage management more accurate, laying a good foundation for scientific inventory management and decision-making.

[ad_2]