Intel’s warehouse management solutions based on RFID technology

[ad_1]

In the traditional supply chain management, the mobile phone for commodity circulation information not only consumes a lot of manpower and power, but also is slow and error-prone. This not only delays the timely decision-making within the enterprise, but also communicates with trading partners in a timely manner. Seriously hindered. The digital supply chain solution recently launched by Intel Solution Services can fully solve this problem.

Solution service department dedicated to technology promotion

As we all know, Intel has chips with a strong position in the market, ubiquitous processor platforms, and advanced technologies and equipment such as RFID, wireless sensor networks (WSN), and real-time location systems (RTLS). In order to accelerate the global application and promotion of these technologies and equipment. Intel has set up a small and sophisticated professional services department-Intel Solution Services Department, whose mission is to provide customers with professional consulting services, help build cost-effective and innovative solutions, and give full play to the value of Intel architecture to help Customers solve business problems or create business opportunities. The Intel Solution Services Department has a total of 300 employees, including nearly 180 consultants. They are located all over the world, and most of them work in Intel’s more than a dozen solution centers. At present, the solution services that the department has formed are mainly concentrated in the four aspects of digital supply chain, digital communities and enterprises, future data centers, and digital healthcare.

The digital supply chain solution is to use high-quality product data and a highly effective data collection mechanism to achieve better collaboration within the enterprise and between trading partners. It can also help users in the same supply chain to simplify the decision-making process and improve Product manageability, provide better service. RFID, WSN, RTLS and other technologies have played an important role in it. What will be introduced here is one of Intel’s digital supply chain solutions-a warehouse management solution based on RFID technology.

Problems faced by the IoT storage center

With the development of the market economy, the demands of consumers are increasing day by day, and they need higher levels of services and more competitive prices. To this end, companies must consider various means to reduce costs. One of the most important means is to carry out centralized distribution through the warehouse distribution center, organize logistics activities more effectively, and achieve the purpose of controlling logistics costs. At the same time, centralized storage of materials and maintenance of reasonable inventory, improve service quality and broad sales. At present, many warehousing and distribution centers cannot effectively organize logistics. The problems they face are mainly manifested in the following aspects:

1. Inaccuracy of inventory statistics

Because some barcodes are unreadable or some thoughts are wrong, inventory statistics are often inaccurate, which affects the distribution center to make correct decisions.

2. Irregular order filling

Many orders are not filled in correctly, so it is difficult to ensure that the distribution center can deliver the correct required goods to the correct location every time.

3. Goods loss during transportation is always a problem that plagues distribution centers.

The reasons for the loss are caused by the misplacement of the goods, loss of the goods by theft, and errors in packaging or shipment. According to a survey in the United States, the loss of goods in the retail industry can reach 1.71% of the sales volume, and the loss rate of Chinese companies is much higher than this figure.

4. Count the goods

The efficiency of clearing goods with traditional methods is very low, and in order to know the inventory status in time, it is necessary to count at any time, which requires a lot of manpower and material resources.

5. Labor cost

Labor costs are constantly rising. Statistics show that labor costs have risen to 30% of the entire supply chain cost.

Intel’s logistics and warehousing center solutions

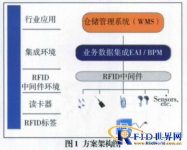

The complete industry solution composition based on RFID technology is shown in Figure 1.

The bottom three levels (namely, RFID tags, card readers and RFID middleware) complete the process of data collection, filtering and combination; and the upper two levels (business data integration and warehouse management system) indicate how Combine RFID technology with traditional business.

With the development of IT technology, more and more companies are introducing advanced IT technology and systems into corporate management. RFID technology, as a mature and advanced technology, has been successfully applied to logistics and warehousing center solutions in recent years middle.

The main functions of this solution are as follows:

Warehousing and inspection

When the goods affixed with radio frequency tags arrive at the distribution center, the reader at the entrance will automatically read the tags, and based on the information obtained, the management system will automatically update the inventory list. At the same time, according to the needs of the order, the corresponding goods will be sent to the correct place.

Organize and replenish goods

The delivery vehicle equipped with a mobile reader automatically sorts the goods, and automatically delivers the goods to the correct location according to the instructions of the computer management center. At the same time, the inventory list of the computer management center is updated to record the latest product location. The inventory replenishment system will Automatically send an application to the management center when the inventory is not enough for the specified quantity. According to the order of the management center, the corresponding quantity of goods will be replenished at the appropriate time. When sorting the goods and replenishing the inventory, if it is found that the goods are stacked in the wrong location, the reader will always Report to the management center, and according to the instructions, the truck will restack these goods to the designated correct location.

Order filling

Through the RFID system, the inventory and management center are closely linked. The order filling in the management center integrates delivery, outbound, inspection, and inventory update into a whole, which minimizes the occurrence of errors and greatly saves manpower.

Outbound transportation of goods

After applying RFID technology, cargo transportation will be highly automated. When the goods leave the warehouse at the distribution center and pass the effective range of the reader at the warehouse exit, the reader automatically reads the information on the label of the goods without scanning, and the goods out of the warehouse can be directly transported to the retailer. The speed of the entire transportation process Greatly improved.

Application of RFID technology in logistics warehouse center

The application of RFID technology in the entire cargo storage process is shown in Figure 2. The system records the information of the cargo at any time and automatically updates the inventory list. This process greatly simplifies the system’s cargo inspection and storage procedures, eliminating the need for cumbersome inspections, Records, counts, and other tasks that require a lot of manpower.

The application of RFID technology in the entire process of goods delivery, as shown in Figure 3. When the goods are delivered, the reader recognizes the goods and automatically performs various defined operations. At the same time, all goods avoid unreadable barcodes and storage in the wrong location, etc. When the situation arises, the accuracy rate is greatly improved.

Through the specific application of RFID technology in logistics storage centers, it is not difficult for us to see the use of information technology. It saves a lot of costs due to manual document processing, and at the same time reduces possible product management errors. Employees are freed from the inefficient manual processing station and concentrate on how to create higher efficiency at lower costs. The purpose of Intel Solution Services is to focus on business value and focus on solving the challenges faced by customers, rather than Intel’s own technological advantages. Because this kind of solution close to the user works better.

[ad_2]