Power metering asset management system based on RFID technology

[ad_1]

Shenzhen Quanshunhong Technology Co., Ltd., as the agent of ThingMagic, brings high-quality UHF for system integration based on the needs of RFID developmentRFIDModule, UHF UHF RFID read-write equipment; this article is based on the application of RFID technology in power asset management and introduces how ThingMagic UHF RFID read-write equipment is implemented.

1. Application background

The power metering center is the power metering and testing organization in the power industry, and it is responsible for the safety life cycle management of power metering instruments in its jurisdiction, including procurement, warehousing, testing, distribution, installation, operation monitoring and other links. With the deepening of the urban network transformation and the in-depth work of one household, one meter for residents, the number of newly installed meters for electricity has increased sharply, and traditional metering centers are unable to meet the requirements. New power metering centers are constantly being built, and the management of electric energy meters is “independently”, and the logistics cost is extremely high, which often triggers customer complaints. Implement full life cycle management of metering devices, including procurement, warehousing, verification, distribution, quality monitoring and other links. In order to realize intensive management, the metering center attaches a unique “barcode ID card” to each electric energy meter. From delivery, verification, inspection, lead sealing to storage and use, every link is “scanned management”. The status of any electric meter can be found at any time.

The use of bar code technology for data collection of electricity meters has improved the management ability of the electricity meters to a certain extent, but this collection method requires warehouse staff to scan each meter that needs to be in and out of the warehouse separately, and the barcode is scanned when scanning. The beam of the gun must be aimed at the bar code surface of the meter label. The bar code surface must be kept clean and tidy, with low efficiency and low accuracy. At the same time, because the meter is a four-layer meter turnover box, when scanning the meter bar code, the staff needs to turn out the bottom layer of the meter for scanning operation, which brings great inconvenience to the staff and greatly reduces the warehouse management staff. Work efficiency and increase workload. The constant flipping of the electric meter while scanning will wear out the appearance of the electric meter and affect the quality of the electric meter. Sometimes accidentally dropping the meter to the ground will cause the meter to be directly scrapped, which adds to the cost of warehouse management. Every time the warehouse management staff scans the barcode data of an electric meter, it needs to be uploaded to the data center in real time for data verification. In the case of poor network status, the in and out of the warehouse will not be able to proceed normally or the work progress will be very slow.

Bar code technology has changed the management method of power metering center assets. However, with the development of metering center business and the urgent need to improve management efficiency, bar code technology is becoming more and more “powerless”, building a more advanced data collection method, greatly improving Warehouse management benefits are of great significance.

2. System introduction

RFID is not only the barcode technology, but also the technology that has caused a revolution in the field of automatic identification. It uses wireless electromagnetic waves to identify the identified items. Compared with the traditional bar code technology, RFID has a faster data communication speed, a longer identification distance, less stringent requirements for the surface cleanliness of the identified items, and higher reading accuracy; At the same time, its unique tag anti-collision algorithm supports simultaneous reading of a large number of item information, which can read up to dozens of asset electronic tags per second, and radio frequency can penetrate the plastic box to read the data of the underlying asset electronic tags Information greatly reduces workload, improves management efficiency, and reduces operating costs.

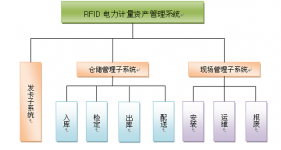

Use RFID technology, learn from the full life cycle and logistics management model, carry out business process reengineering, establish a dynamic and refined management of the whole process of the measurement device, and establish a supporting information technology support system to realize the measurement of assets from warehousing, on-site to scrapping. It can identify accurately and efficiently, realize the dynamic management of the whole process of the measurement asset logistics process and the on-site work process, establish the integration of production management and marketing management, and realize the asset life cycle management of the measurement equipment.

1. Establish a measurement device management workflow based on RFID technology and modern logistics technology, improve and optimize the existing operation methods, gradually replace the existing method of managing equipment through bar codes, introduce new management methods and methods, and improve measurement standardization Work level and efficiency, establish a new management model;

2. Through the introduction of radio frequency identification technology, measurement assets can be easily identified from storage, on-site to scrapping, solving the problems of weak measurement asset foundation and difficulty in collecting on-site ledger data, and providing users with a full range of asset tracking management methods ;

3. Strengthen the management and control of on-site operation and maintenance work. Through RFID technology, it can accurately identify on-site equipment. At the same time, relevant equipment and user information can be inquired in time on the site, and on-site operation and maintenance information can be entered, which improves the efficiency of on-site operation and maintenance and strengthens The supervision and management of on-site operation and maintenance work has been improved, and customer satisfaction has been improved;

4. Realize the interface with the SG186 marketing system and warehousing management system, establish a more accurate data foundation and more efficient data exchange, and comprehensively improve the efficiency of measurement asset logistics management;

5. By attaching a composite electronic label to each measurement asset, a unique identification is established for each measurement asset, which lays a solid data foundation for the improvement of future marketing business work and the application of related information management methods.

Three, system plan

The RFID printer can print RFID electronic labels to complete the initialization of the electronic labels. Through the physical binding of RFID electronic tags and metered assets, and through background data, the electronic tag information is associated with the identity information of the metered assets. At each subsequent node, the electronic tag information can be obtained through the RFID reading and writing device to achieve the measurement of the asset. Identification of identity. This is the core of the entire system.

2. Process design

Establish a refined management application system for power metering assets based on RFID technology, optimize existing business processes, and realize a dynamic logistics management model, from leaving the factory, warehousing, verification, exporting to distribution, installation, operation and maintenance and scrapping of power metering assets And other nodes realize the refined and dynamic management of the whole life cycle. The system flow design is as follows:

2.1 Card Issuing Subsystem

Combining the actual environment of meter asset management and on-site work, design a composite electronic label design that meets actual work requirements. In addition to using RFID tags on the meter, the barcode label is still retained to provide convenience for other business applications, while retaining The continuity of existing technology applications.

RFID printer can complete this job well. In addition to efficiently writing RFID data, it can also print bar codes on the surface of the electronic label, which is a good way to issue cards.

2.2 Warehouse Management Subsystem

At the end of the production line, the power metering assets pastes the printed RFID label on the inside of the equipment, and the label has written information such as the asset number of this batch of equipment in advance. After being transferred to the metering center, efficient warehouse management can be realized.

Storage link:

The asset management team unpacks the metering device with the electronic label pasted by the supplier and puts it in the turnover box. Through the RFID fixed reader installed on the warehouse conveyor belt, it automatically obtains the information of the arrival measurement asset and transmits the information For the warehouse management system, realize the large-scale, fast-reading warehousing operation of measured assets.

Delivery link:

According to the business acceptance and inventory situation, through the outbound RFID reading device channel, the pallet-level metering assets can be batched out of the warehouse at the same time; collecting multiple turnover box tags and the metering asset tag information in the turnover box at one time, and The outbound task list is automatically checked. Provides a list of outbound assets, and can print the current outbound asset list; compare and verify the outbound assets. If there is an inconsistency between the outbound equipment and the outbound list, the system will give an alarm and require warehouse management. After the equipment is successfully shipped out of the warehouse, the status will be changed to “pre-collected and ready to be installed”.

In other links of warehousing, according to the number of assets to be operated, RFID handheld devices and RFID fixed devices can be used to perform other operations such as verification and distribution of assets, including correction operations of electronic tag data, verification operations, and so on.

2.3 On-site management subsystem

This part mainly uses RFID handhelds to measure assets after they are out of the warehouse. At the scene, staff perform installation, operation and maintenance and scrapping operations.

When installing on site, read the RFID tag on the device and confirm that the device information is consistent with the information on the business worksheet before allowing installation to prevent human errors in the recording and business process carry-over process. You can also download the business worksheet In the handheld, directly fill in the installed equipment information into the business worksheet after the installation is completed to ensure the accuracy of the data. After the equipment is installed, the asset status can be changed through the handheld. When the business is changing the meter, the meter change and the meter installation index can be recorded through the handheld device, and the information can be easily transmitted back to the marketing system. In daily maintenance, the staff obtains the past operation and maintenance information of the metered assets by reading the RFID electronic tags and adds and updates the latest maintenance information. For equipment that has reached the end of life treatment, the system will automatically remind the staff to scrap it, so as to complete the management of the full life cycle of the measurement asset.

Four, system highlights

The system uses the latest international automatic identification technology-radio frequency identification RFID, combined with modern computers, automatic control and other comprehensive cross-domain technologies, relying on ThingMagic M6’s powerful multi-tag anti-collision algorithm, high-speed information reading and processing capabilities, and stable performance The feature of easy integration realizes automatic identification, informationization and intelligent management of power metering assets.

ThingMagic M6 has a reading speed of 750 tags per second, a core anti-collision algorithm, and high-speed information reading and processing capabilities, which can maximize the efficiency of the warehouse management of power metering assets while ensuring the correct rate. The improvement of efficiency must be based on the correct rate, ThingMagic M6 takes the balance of the two to the extreme.

At the same time, ThingMagic M6 has a small size, high protection level, suitable for harsh working environments, and has a POE function, which is especially suitable for simple and stable applications in an industrial environment. ThingMagic M6 has an enterprise-level MercuryOS embedded operating system, provides strong software support, and provides a complete RFID-based power metering qualification management system for the metering center.

As a leading RFID brand-Trimble’s ThingMagic agent, Shenzhen Quanshunhong Technology Co., Ltd., while providing all major operators/integrators with ThingMagic’s full range of products, is committed to cooperating with operators/integrators to promote ThingMagic Frequency RFID equipment is applied to various applications such as aviation shipping, warehousing logistics, clothing retail, manufacturing, anti-counterfeiting and traceability.

With a professional technical team, high-quality service and preferential prices, Shenzhen Quanshunhong Technology provides our customers with world-class RFID equipment solutions and high-quality after-sales service.

[ad_2]