Power Patrol Management System

[ad_1]

I. Overview

In the management of substation equipment, a large amount of information representing the operating status of the equipment is collected and processed by manual inspection and recording. Therefore, the quality of data collection mainly depends on the professional quality of the workers. Due to personnel differences, the inspection attitude and work ability of inspectors are not the same, especially in terms of inspection time, inspection route and inspection content, it is difficult to achieve quantitative management; after the inspection, the equipment inspection records are only filled in based on experience; the inspection content, Inspection items, defect records, etc. are also not standardized enough… This type of data is highly dispersed and not real-time, and human factors have a great impact on the accuracy and effectiveness of the data. The special system for standardized inspections using high-frequency electronic tags realizes the standardization of daily inspections, the standardization of data records, the quantitative management of work performance, and the ability to query accident responsibilities.

2. Features of this system

The standardized inspection special system using high-frequency electronic tags reduces the influence of human factors in traditional inspection management, and has the characteristics of practical content, convenient work, and simple operation.

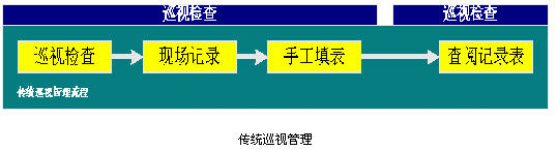

In traditional patrol management, patrol personnel conduct patrol inspections, rely on work experience and proficiency to collect and record on-site data, fill in data sheets manually, and form record sheets.

The dedicated system for standardized inspections implements standardized management and standardized operations. Workers use a unified handheld device to record. If the equipment and system are normal, the handheld device will automatically record without the need for staff to operate; if the equipment and system are defective, the worker can use the handheld device to record on-site and record the defect truthfully In the database. In this way, normal records and defective records will be stored in a huge database. The management system uses the database to view and check the operation of the equipment and system, conduct daily operations and management analysis, and the system will generate inspection logs every day. There are defects. If yes, a defect notice will be generated, and then a defect record table and a defect statistics table will be formed based on the defect notice for accountability traceability.

Through the comparison of traditional patrol management and standard patrol system, we can see that compared with traditional methods, this system not only greatly reduces the influence of human factors, but also simplifies, standardizes and standardizes operations, greatly improving work efficiency and practical effectiveness.

Three, technical solution selection

The UHF RFID technology used in the standard patrol system is greatly improved compared to other technologies in terms of operation and accuracy. The following table is its comparison with barcode technology and inspection stick.

Item Barcode Technology Inspection Rod UHF RFID

Visibility Must be visible Must be visible Not visible

Reading distance 2-3cm contact type 50-100cm

Rainy day unreadable unreadable unreadable readable

Code changeability Can not be changed Can be changed Can be changed

Power supply None None None

From the table, we can see that the barcode technology and the inspection stick must be visible, while UHF RFID technology can complete the work without being visible; the inspection stick must be contact-type when reading, the barcode The reading distance of the technology is only 2-3cm, while the reading distance of UHF RFID technology can reach 50-100cm. In addition, under severe weather such as rain, barcode technology and inspection sticks cannot be compared with UHF RFID. For example, both are unreadable before raining, while UHF RFID can work normally. Finally, the barcode technology and the code of the inspection stick cannot be changed, while UHF RFID has no such obstacle, and the code can be changed arbitrarily , This is a major breakthrough in this technology.

Four.The composition of the patrol management system

The patrol management system is mainly composed of four parts: ultra-high frequency passive electronic tags, special patrol handheld devices, management computers and system software, and patrol management database.

The UHF passive electronic tag works in the UHF frequency band by frequency hopping, and has good anti-electromagnetic interference performance; the tag has a long service life and does not require a power supply during operation. After being packaged, it is waterproof and dustproof and suitable for outdoor environments; it The operating distance is long, and the operating distance of the small scanning device can reach 0.5m-1m; and the information in the tag can be changed and encrypted.

The dedicated handheld manipulator is based on ARM9 hardware platform, adopts Win_CE operating system, and has a color touch display screen; it can recognize EPC_Class1 standard electronic tags, built-in antenna, and the operating distance can reach 0.5m-0.7m; it also has support for mobile databases and support Chinese handwriting input and other advantages.

The management computer and system software take the database as the core, including six main functional modules: input module, query module, change module, interface module, analysis module and output module. The input module is mainly responsible for the input of basic information and the information of the handheld operator. Upload; The output module is mainly responsible for printing various reports and downloading information from the handheld operator.

five.data processing

The source of the data is mainly the handheld operator, which can work independently and has the advantages of local storage and regular upload to the database. The data processing of the database can provide management analysis help for management personnel, including the evaluation of equipment and personnel, etc. The data processing of the database also provides equipment-level records and file information for the operators.

The realization method of data processing is relatively simple, that is, the information of the equipment and the system is entered into the database through the handheld operator, and then the result of the data processing and the information formed are fed back to the manager and the operator through the database.

[ad_2]