RFID emergency material warehouse management system solution

[ad_1]

1. Project Overview

1.1 Project background

Emergency relief materials are life-saving materials that must be allocated and distributed to the disaster site accurately and accurately whenever a disaster occurs. Delays and errors for any reason are not allowed. In order to standardize the information management of emergency supplies, enable high-level sharing of relevant data, timely feedback of information, and further improve the flood prevention and disaster mitigation system, Hangzhou Dongshi has established a set of RFID emergency supplies management information system comprehensively using Internet of Things technology and mobile communication technology. Through intelligent material management, emergency materials can be managed more intelligently and efficiently, and the management level of flood control and drought relief materials can be improved.

The application of radio frequency identification (RFID), the latest technology product, can fundamentally solve the above-mentioned problems. Based on radio frequency identification (RFID) technology, Dongshi has developed an RFID emergency rescue material management system according to the actual situation and needs in material storage management.

1.2 Project goals

In the application of the RFID emergency rescue system, an electronic tag is affixed to each cargo, and the specific information of the cargo, storage location and other information are written in the tag in combination with related software. In the warehouse, fixed or hand-held readers can be used to identify and detect the circulation of goods, and at the same time, the preservation period of the goods can be tracked.

The RFID warehousing logistics system is mainly to achieve the following goals:

·Standardize storage location management to facilitate finding goods

Through the display screen, and the shipment order and other information, the system automatically displays the cargo location information, without manual judgment and decision. So as to get rid of the dependence on manual judgment to the greatest extent, and improve the quality management level of the enterprise.

·Improve the reliability of data in ERP system and WMS system

The data acquisition system minimizes and reduces manual intervention, thereby reducing the number of manual operation errors. Moreover, the system strictly controls the input data to ensure the integrity and consistency of the data during the operation, so that the data entering the system is clean and effective. It not only provides reliable data for the operation of enterprise information management systems such as ERP systems and WMS systems, but also enhances the value of information management systems.

·Efficient and accurate data collection to improve work efficiency

RFID technology’s unique large-volume data collection at the same time, without the need for precise alignment and other features, frees enterprises from a large number of repetitive tasks every day. Frequent large quantities of incoming and outgoing data are collected in real time through the RFID system, transmitted in real time, checked and updated in real time, which not only reduces manual labor intensity but also avoids errors in repeated manual operations such as false scans, missed scans, and rescans. Improve work efficiency and accuracy.

·Use scarce resources accurately and efficiently to improve production capacity

Industrial-grade flat panels and RFID readers are installed on the forklift, which can automatically collect product information during the operation process to further improve the operation capability of the system.

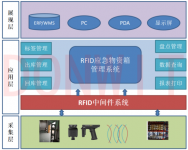

2. System Architecture

3. RFID process design

3.1 Hardware solution

3.1.1 Material labelling scheme

It is recommended to use self-adhesive labels, which can be printed, the picture is as follows

3.1.2 Pallet labeling scheme

The metal tray adopts anti-metal label.

3.1.1 Location label

Location tags are installed in each location in a buried way.

3.1.2 Forklift modification

An RFID reader is installed on the forklift to collect location tag information, and an on-board computer is also installed to display the collected information.

3.1.3 Large screen installation

A display screen is installed at the entrance of the finished product warehouse to display the information of incoming and outgoing goods.

3.1.4 Installation of temperature and humidity sensor

According to the actual situation, the emergency material warehouse installs temperature and humidity sensors in the photo area.

3.1.5 Lighting control system installation

Emergency material warehouse, install light control system according to the photo zone.

3.2 Process design

3.2.1 Label binding

Each pallet label has a unique number. Before the goods are stored in the warehouse, the RFID handheld machine is used to scan the goods information and the pallet bar code information, which are automatically bound, and the data is transmitted to the back-end system via WIFI.

3.2.2 Inbound and Shelves

Log in to the system before warehousing. When the forklift picks up the goods, the reader on the forklift purchases the goods information, and the system automatically allocates the location information that needs to be put into the warehouse. The specific process is as follows:

·Access to the warehousing system

·Forklift pickup

·Read RFID tag information, the system automatically allocates location information

·Forklift workers find the corresponding location according to the allocated location information

·Read the location label,

·If the location information is correct,

·The on-board computer prompts that the location information is correct, and the goods are released

·Manual confirmation

·If the location is wrong

·The on-board computer prompts that the location information is wrong, and the goods will not be released temporarily

·Manual assistance to find the reason

·Continue to find the corresponding storage location until the storage is correct

3.2.3 Delivery

Log in to the system before leaving the warehouse, and the system will prompt the corresponding location to reduce the time of manually searching for the location. The specific process is as follows:

·Access to the warehouse system

·According to the outbound list, the system will automatically prompt the relevant location information

·According to the location information, manually find the corresponding location

·RFID reads goods information and location information at the same time,

·Pickup, manual confirmation

·Pass RFID access control

·The system automatically collects forklift cargo

·Determine whether the goods out of the warehouse are correct

·If it is correct, the delivery is completed

·In case of error, manual assistance to find the reason

3.2.4 Inventory

When taking inventory, a handheld computer is used to scan the goods in the warehouse, and the data is automatically uploaded.

The general business process of inventory is as follows:

·The planning department (or the financial department) issues an inventory notice to prepare for the inventory

·The warehouse manager receives the order, finds the corresponding location, starts the inventory, turns on the handheld, and scans the product RFID tag information

·Scanned data is automatically transmitted to the ERP system via wireless

·After the ERP system receives the collected information, it compares it with the book data in the system to determine whether the results are consistent.

·If unanimously confirm the inventory is completed

·If they are inconsistent, give an alarm, find out the difference between the physical object and the ERP system data, confirm it manually, and process the difference result

3.3 Introduction of RFID emergency material management system:

The RFID emergency material management of Hangzhou Dongshi Technology is mainly divided into three parts:Back-end system software adopts BS architecture; channel data acquisition software adopts CS architecture; mobile APP software, Android system.The main functions are as follows:

·Hand-held functions: storage in, out of storage, relocation, inventory

·RFID printer function: add storage

·Access door function: warehouse in and out

·Back-office functions: warehousing and export, historical query (export), warehouse transfer, warehouse management, material classification, authority management

·Large screen display: real-time loading and unloading status display and statistics

[ad_2]