RFID fixed asset management

[ad_1]

1. The needs of the times

1.1. Application scope

The global business competition in the 21st century is not only a single competition in the fields of technology, cost, and management, but also a comprehensive competition between the advantages and disadvantages of the global supply chain. Improving production efficiency and reducing operating costs are vital to companies. They quickly recognize the problems in warehouse management, and improve, design and establish a complete warehouse management process to improve warehouse turnover and reduce The occupation of operating funds turns frozen assets into cash and reduces the cost caused by the elimination of warehousing. The multinational commercial retail giants have invested heavily in their supply chain strategy, planning, operation management, distribution center planning, warehouse planning, etc., using today’s most advanced science and technology to establish a fast and efficient operating system.

useRFIDTechnology, manage the entry and exit of goods in warehousing and logistics, mark pallets, simplify the operation process, improve work efficiency, and reduce the labor intensity of workers.

1.2. Status Quo and Analysis

Existing warehouse logistics management systems usually use barcode labels or manual writing of warehouse logistics management documents to support existing warehouse management. However, the shortcomings of barcodes such as easy copying and non-moisture resistance, as well as the cumbersomeness of manual writing of receipts, can easily cause human losses and other unavoidable things. The efficiency of warehouse management based on manual operations is very low, and it is time-consuming and labor-intensive in cargo classification, cargo search, and warehouse inventory inventory, which makes current warehouse management always suffer from defects.

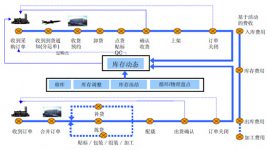

RFID technology is used for intelligent warehouse logistics management. First, electronic tags are affixed to each goods, and the information of the readers in each channel of the channel warehouse is used to determine the goods in, out, allocation, shifting, inventory counting, etc. Process, automatic data collection through RFID reader data, to ensure the speed and accuracy of data input in each link of warehouse management, to ensure that enterprises can accurately grasp the real data of inventory in a timely and accurate manner, and to achieve efficient cargo search and real-time inventory counting. It is helpful to improve the efficiency of warehouse management, get rid of the time-consuming and laborious traditional warehouse management, reasonably maintain and control enterprise inventory, and enable the enterprise to operate efficiently. Through scientific coding, it is also convenient to manage the batch and shelf life of items. Using the system’s location management function, you can even query the current location of all inventory materials.

2. System Introduction

2.1. System Principle

The warehouse management system design adopts the following three-tier structure:

Information collection layer

Through issuing and labeling, new goods are equipped with RFID tags. The unique ID number of the tag or the code written by the user can identify the goods. The reader can automatically collect tag information, so as to realize the information collection function of the goods.

Data transfer layer

The cargo label information collected by the RFID reader can be transmitted to the back-end system for analysis through the relevant communication interface. The communication interface of the transmission can be selected according to user needs, such as RS-485, RS-232, Ethernet, WIFI Or GPRS, etc.

Cargo management

After the PC terminal or the back-end data center receives the data from the reader, it analyzes the data to determine the flow of goods out of the warehouse, warehousing, moving, and inventory, and at the same time generates a corresponding report indicating the detailed list, and makes the corresponding in the system的处理。 Treatment.

2.2. System structure

The hardware of the RFID warehouse management system is mainly composed of RFID tags, fixed readers, handheld readers, servers, personal computers, etc., through the network to achieve mutual connection and data exchange.

The RFID warehouse management system software is composed of a supply chain management system, an RFID tag issuing system and an RFID tag identification collection system. These systems are connected to each other to jointly complete the various processes of item management.The back-end database management system is the core of the whole system, and RFID identification collection is the basis and means to realize the management function

3. System Features

3.1. Realize first-in first-out management of goods

The RFID warehouse management system uses advanced RFID technology, wireless local area network, database and other advanced technologies to combine the entire warehouse management with radio frequency identification technology, which can efficiently complete various business operations, improve warehouse management, and increase efficiency and value. For each batch of goods in the warehouse, the storage time, storage location and other information are automatically recorded by the system. When the goods are out of the warehouse, the first-in first-out management of the goods can be realized on this basis.

3.2. Real-time management of warehouse inventory

The inventory management of the original warehouse relied on manual reports and manual statistics, which led to the inability of various departments to understand inventory information in a timely and accurate manner. In addition, with the development of business, the number and variety of daily incoming and outgoing goods gradually expand, and customer needs are becoming increasingly complex. Whether real-time management of warehouse inventory can be achieved has become an important factor affecting the establishment of a fast and efficient operating system. The RFID warehouse management system can accurately grasp the inventory situation of the warehouse in real time, and provide a scientific basis for leaders at all levels and related departments to optimize inventory and make production and operation decisions.

3.3. Material tracking and graphical management

On the basis of realizing cargo pallet position management, the system can also realize the functions of material tracking and graphical management. This function allows the stock materials to be reflected in a graphical manner very intuitively and quickly. Greatly improve the storage efficiency and precision of item management. Improve the recognition rate of items in and out of the warehouse, without opening the box for inspection, and identifying multiple items at the same time, improving the efficiency of in and out of the warehouse.

3.4. Reduce inventory cycle and reduce distribution costs

The traditional warehouse inventory is time-consuming and laborious. The RFID warehouse management system reduces the warehouse inventory cycle, improves the real-time data, dynamically grasps the inventory situation in real time, and realizes the visual management of inventory items. Improve the efficiency and accuracy of the picking and distribution process, accelerate the speed of distribution, and liberate the labor force.

4. Other application areas

1) Military material management of the army

2) Tobacco logistics warehousing management

3) Medical drug inventory management

4) Retail inventory distribution management

5) Warehouse management of materials and finished products for large enterprises

6) Airport consignment classification and distribution management

7) Related types of applications such as port and terminal container cargo management

[ad_2]