RFID management system for real-time monitoring of fixed assets in computer room

[ad_1]

1. Introduction to the system

For companies, important fixed asset management has always been a headache. Check the actual accounts; understand the configuration parameters of important assets at a glance; master the operation and maintenance of important assets. How to accurately and quickly grasp the relevant information is the problem to be solved by this system.

RFID is a kind of radio frequency identification technology, which is composed of readers, antennas and tags. When the tag is close to the sensing range formed by the reader and antenna, the tag will send the data stored in the chip to the reader, and the reader will upload the data to the information system.

Due to the large amount of stored data, fast reading speed, and no need for human intervention in the process of reading data, RFID can perform rapid asset identification and inventory. Achieve accurate and rapid grasp of important fixed asset information.

This system consists of:

electronic label

Fixed split type reading and writing equipment for on-site real-time monitoring and inventory

RFIDwince handheld terminal reading and writing equipment

Smart multi-antenna splitter

RFID antenna

Control computer and system management software, etc.

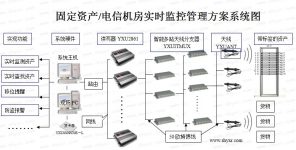

System function and system diagram

1. Real-time monitoring of the number, attributes and location of assets;

2. Anti-theft: when the asset leaves the location without authorization, the alarm can be alarmed, and the anti-tamper tag is removed to alarm;

3. Prevent disorderly placement. If you are only doing entry and exit management, you don’t know where you entered. Real-time monitoring can eliminate this problem, but the administrator can be reminded if the asset is not where it should be;

Two, system architecture

The system hardware architecture includes: fixed split reader, RFID antenna, RFIDwince handheld terminal equipment, electronic tags and back-end server;

Data exchange method: It can be implemented in two ways, one of which is selected according to cost requirements:

Online data exchange, real-time transmission of field data to the back-end information system through a fixed split reader for processing and analysis. Offline data exchange. After the field data is collected through the wince handheld terminal device, it is imported to the back-end information system for processing and analysis.

The overall system structure of the system is: Multi-tire C/S combined with Browser/Web Server/DB Server

3. Software system design

System platform win2003+ database

Software system function design

Basic information management

Regional information, computer room information, cabinet information, coding rules, server information, printing styles

system maintenance

Data backup, operator, change password, system log

Computer room management

Cabinet query, warehouse receipt, warehouse receipt, inventory, report center

Server management

Server increase, server decrease, usage, configuration list, report center

Operation and maintenance management

Server repair and regular maintenance

Handheld device data import

Four, business operation process

1 Encode the cabinet in the computer room, enter the coding information into the system and the RFID tag, and fix the RFID electronic tag on the cabinet.

2 Encode the server, enter the encoded information into the system and the RFID tag, and fix the RFID tag on the server.

Arrange antennas and fixed split readers in the cabinet according to the requirements of the range of reading tags

Five, the server enters the computer room process

After querying the location of the cabinet in the computer room where the system server is placed, a list of production warehousing operations. The job list must at least include information such as the cabinet number and server number. The operation and maintenance personnel transport the server to the designated computer room according to the requirements of the operation list, and the personnel on duty in the computer room confirm the warehousing operation through the warehousing work order generated by the RFIDwince handheld terminal. After the operation and maintenance personnel put the server in the designated location according to the requirements of the warehousing operation sheet, scan the cabinet number and server number through the RFIDwince handheld to confirm that the operation is correct and complete the warehousing operation list. After confirming the cabinet number, server number and server location through the RFIDwince handheld terminal, the personnel on duty in the computer room complete the warehousing work order.

Six, computer room inventory process

The person on duty in the computer room opens the system inventory interface and imports the inventory information to the RFIDwince handheld. The staff on duty first read the RFID tags of the cabinets for confirmation, and then read the electronic tags of the servers in the cabinets in turn. If the tag data read in the cabinet is consistent with the inventory data imported into the RFID handset, the interface is green, indicating that it is passed. If the inconsistent handset interface shows a red interface to indicate failure, you can choose to restart the inventory or end the inventory after checking. Finally, import the inventory data into the system.

Seven, RFID equipment selection:

System main equipment

The UHF split reader is an electronic tag reader that is compatible with ISO-18000-6B and ISO18000-6C/EPC Class1 Gen2 protocols launched by Shanghai Haobin Information based on independent intellectual property rights. It can be widely used in remote card reading applications such as warehousing and logistics management, customs clearance management, intelligent transportation, asset management, intelligent libraries, and technological production processes.

The split reader can expand or control the effective range of card reading through 1-4 antennas with different gains outside the high-frequency cable, and use the solution of multi-point reading environment.

Size: 110(L)*185(W)*40(H)mm

Weight: 1KG

Working temperature: -10°C to 55°C

Storage temperature: -20°C to 80°C

Humidity: 10% to 95%

Protection level: IP-40

Number of antennas: 4 TNC

Power supply: external 110-240 VAC power adapter

Common frequency range: 902-928 MHz (915M, including European standard)

RF output power: 0-30dBm

Air interface protocol: EPC Class 1 Gen 2, 18000-6B

Communication interface: RJ45/RS485/RS232

UHF RFID antenna splitter is a new generation product developed by our company. The splitter is a UHF antenna splitter with 1-8 interfaces. It can be used for networking and real-time item asset tracking, intelligent shelf distribution RFID antennas, electronic label shelves and their applications.

The antenna splitter is composed of a main antenna splitter and a slave antenna splitter. It adopts an aluminum alloy shell and can be installed in an indoor cabinet or an outdoor protective box with good ventilation, dust and rain conditions.

Each radio frequency output port (ANT1-ANT8) of the main antenna splitter can connect up to 64 RFID antennas, that is, each main antenna splitter can support 8 slave antenna splitters.

Size: 200(L)*105(W)*26(H)mm

Weight: 500g

Working temperature: -10°C to 55°C

Storage temperature: -20°C to 80°C

Humidity: 10% to 95%

Protection level: IP-40

Number of RF output ports: 8 MCX (female)

Number of RF input ports: 1 SMA (female)

Power supply: 12V2A

Frequency range: 860-960 MHz

Maximum RF output power: 33dBm

Communication interface: RJ45/RS232

Product model (order code) YX-UANT-900J

Physical characteristics size 160 (length) * 20 (width) * 10 (height) mm

Weight 0.01KG

Ambient working temperature -70°C to 55°C

Storage temperature -70°C to 80°C

Protection grade IP-00

Connection connector MCX (male)

Gain 1.5dBi

Frequency range 902 – 928 MHz (can be customized as required)

Vertical polarization

Voltage standing wave ratio <1.5

Lightning protection DC grounding

Horizontal plane 3.0dB beam width 70°

Vertical 3.0dB beam width 70°

Input impedance 50Ω

RFIDwince handheld

The UHF long-distance wince handheld terminal developed by Shanghai Haobin Information is the fifth generation product developed by our company. It can read and write RFID electronic tags that comply with UHF EPC Gen2 (ISO18000-6C) and ISO18000-6B standards. It can be widely used in inspections. , Vehicle access management, personnel access control management, electronic anti-counterfeiting, logistics monitoring, production automation management and other data collection systems.

Operating system: Microsoft Windows CE 5.0 operating system multi-language

Processor: SAMSUNG 400 MHz CPU

Memory: ROM128MB, maximum support: 1GB RAM 128MB SDRAM can be expanded through the SD card slot

Display: 3.5in QVGA (240*320 pixels) color transflective TFT-LCD LED backlight

Keyboard function keys: 25+1 alphanumeric backlit keyboard, soft keyboard, support handwriting input

Standard battery: 3.7V 2800mAh/3200mAh lithium ion battery Internal backup battery: 17mAh

Standard communication: USB1.1, RS232

Wireless communication options: support WIFI GSM/GPRS communication

Audio: Built-in speaker can be equipped with stereo headphones (jack: 2.5mm)

Information collection: RFID, barcode scanning, touch screen, stylus

Dimensions: HxWxD: 190x80x25 (mm)

Weight: 400g including a standard battery

Support RFID standards: UHF: EPC Gen2 (ISO18000-6C), ISO18000-6B

RFID reading distance: UHF: 50-150cm

Barcode scanning/resolution rate: 100 times/second Barcode reading angle: 54° High efficiency reading angle: 44°

Compliant with standards: optical safety, IEC 825, first class laser

[ad_2]