Alcohol anti-counterfeiting system and method based on RFID technology

[ad_1]

Radio frequency identification technology (RFID) can realize the tracking and information sharing of items on a global scale through the combination of Internet technology. It is the direction of future enterprise informatization development. RFID technology used in logistics, manufacturing and service industries can greatly improve the management and operation efficiency of enterprises, and reduce circulation costs; used in identification, asset management and other fields can achieve rapid batch identification and positioning, and can be carried out according to needs Long-term tracking management. The alcohol anti-counterfeiting system and method based on RFID technology, using large-scale integrated circuit manufacturing, has the characteristics of high processing difficulty, low cost, and the ability to authenticate product information by enterprises, which will bring a revolutionary breakthrough in alcohol anti-counterfeiting technology.

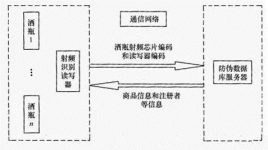

This set of solutions applies RFID technology to wines and other containers with bottle caps, and realizes the anti-counterfeiting of products through the bottle structure design and the back-end authentication system. The system consists of specially designed bottle caps and body, RFID reader, communication network and anti-counterfeiting database server. When the wine bottle is opened, the sharp surface of the cutting device at the mouth of the wine bottle will cut off the connection between the antenna and the chip, so that the RFID reader cannot read the code of the chip on the top of the wine bottle cap, thereby preventing the secondary use of the wine bottle . In this system, in addition to the unique code of the radio frequency chip, the reader also has a unique code, and it is registered in the anti-counterfeiting database of the winery or a third party. The unique code of the reader is bound to the registered user (usually a store or restaurant of the sales terminal), and only the registered reader can query the chip code information. Therefore, only products sold through regular channels can access the anti-counterfeiting database. For consumers, the authenticity of the wine can be judged by checking the information on the display screen of the seller’s reader.

Regarding the realization of this system, wine manufacturers only need to install RFID-related equipment in the processing of wine caps and bottles of the original production line and establish an anti-counterfeiting database. Manufacturers use integrated technology to attach special radio frequency chips and antennas to the original bottle cap and bottle body during production, and register the corresponding codes of these tags in the product information in the anti-counterfeiting database. At the same time, provide the product’s wholesaler or restaurant salesman with a dedicated reader device with a cost of several hundred yuan, and require it to register in the anti-counterfeiting database. In this way, manufacturers can not only understand all the sales terminal segments of the product based on the information provided by the reader, but also make statistics on the sales situation.

The specific usage method of the system is as follows: For unopened wine bottles, a radio frequency chip is attached to the inside of the top of the bottle cap, which is connected to the metal strips at different positions on the bottle cap through the chip leads attached to the inside of the bottle cap wall, located in the wine bottle body The antenna body on the upper part is connected with the metal strip to form a path. The cutting device on the bottle cap is located between the radio frequency chip and the antenna body. The sharp surface of the bottle cap can cut the connection between the two with the rotation of the bottle cap. The writer reads the code of the radio frequency tag, and sends it to the anti-counterfeiting database server by SMS together with the unique code of the reader for authentication. If both codes are authorized, the verification is passed and a confirmation message is sent back; once the wine bottle is opened, cut The device will destroy the antenna, and the radio frequency chip will fail to obtain sufficient excitation voltage, thereby realizing the anti-counterfeiting of the product.

This anti-counterfeiting method uses RFID technology, and mass-produced integrated circuit chips and tag antennas are used on the hardware. It is easy for manufacturers to manufacture, but counterfeiters need to spend a lot of money to imitate these technologies; RFID chip and reader code The unique code is used under the unified coordination of the whole world, which will not give the forgers a gap. At the same time, this dual authentication mechanism is also managed and controlled by the manufacturer, which improves the reliability of the system; after the bottle is opened, no matter what the bottle is It is the bottle cap, and the cutting device can irreversibly damage the chip and antenna path. This also eliminates the use of old bottles to pack new wine, and further cuts off the possibility of success for anti-counterfeiters. Under the guarantee of the above triple anti-counterfeiting design, the reliability of this anti-counterfeiting method can theoretically fully meet the requirements of wine production enterprises.

[ad_2]