Application of RFID in the management of wine enterprises

[ad_1]

RFID technology is an automatic identification technology that emerged from the 1990s and gradually matured. It uses radio frequency for non-contact two-way communication to achieve identification and exchange data. Since the label system needs to use special equipment for identification, the cost and difficulty of imitation and copying by counterfeiters are extremely high.

The anti-counterfeiting advantages of RFID technology are:

1) Each label has a unique ID number, which cannot be modified or forged; it means that every bottle of wine has a unique ID number, and there will be no duplication between any bottle of wine.

2) Each tag also has a certain amount of memory space to read and write data, and the ID number can be specially encrypted, and cannot be copied or forged.

3) The reader has a physical interface that is not directly open to the end user to ensure its own security; it is difficult for fake readers to forge the reader.

4) Long service life, no mechanical wear, no mechanical failure, passive work, can work in harsh environments, anti-fouling, long data reading distance, etc.

In addition, a logistics and supply chain management system based on RFID technology can be established. Information can be written to electronic tags, such as wine brand, type, production date, time and other identification information. Through this system, the entire process of production, storage, sales and delivery of each bottle of wine can be recorded, and information such as output and sales can be automatically counted. While achieving the anti-counterfeiting effect, it can achieve multiple goals, realize the information management of management, and help manufacturers solve the problem. “Chain of goods” issues, such as:

1) Control product quality: Product quality is the life of an enterprise. Through the full tracking and collection of the RFID system, the quality information of the product can be tracked and collected in a comprehensive manner. Quality problems can be found in time and the information can be fed back to product design, production management, quality management and operation in time Decision-making department to help companies improve product quality in an all-round way. For any bottle of wine, the source of its production can be traced.

2) Supervision and management of salespersons: Salespersons conduct sales activities based on corporate thinking and take product label information as guidance to improve the management level of the sales team.

3) Formulate a reasonable service strategy: Through the collection of RFID tag information on the product, the tracking of product quality and after-sales service enables companies to accurately understand and judge product quality and user feedback, thereby helping companies to control product quality and update service strategies in time , Improve the competitiveness of enterprise products.

4) Strengthen the control and management of the market: Through the collection and feedback of product sales information, the division and hierarchical management of sellers has been realized, and the healthy and orderly development of the market has been ensured. It can effectively control regional backlogs, and at the same time follow up and evaluate sellers, which is conducive to the correct selection of sales partners and promote market sales.

5) Guide the product design positioning of the company: Based on the product label information, a complete product file and user file have been established. This is undoubtedly a huge asset for the company. The distribution of users and user feedback are important for the product design positioning of the company. Market positioning is of great guiding significance.

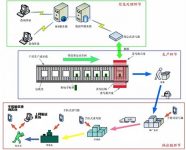

Wine RFID dynamic product traceability system

Based on the problems and management needs of the existing production and sales links of alcohol production enterprises, Fiberhome Electronics has customized a dynamic product traceability system solution. The solution uses RFID global unique markings, a combination of multiple codes and one for anti-counterfeiting, and batch scanning without opening the box. And a variety of query methods and other technologies to help wine production companies realize product dynamic tracking from various links such as raw wine management, production data collection, food safety management, warehousing management, logistics management, and product traceability.

The dynamic product traceability system based on RFID technology developed by Fiberhome Electronics has successfully solved the stubborn traceability problems that plagued alcohol production enterprises. Through the product dynamic traceability system, the process data of the whole life cycle of the wine is recorded, and the product is easily anti-counterfeit and released. Function; the system responds to the requirements of the “Food Safety Law” and can quickly recall problem products to ensure the legitimate rights and interests of consumers.

Let’s take a look at how the wine dynamic traceability system guarantees product safety.

1. From the source of the production line to the bottle being opened, product information is recorded and traced throughout the entire life cycle.

2. Anti-sweeping method: The wine is scanned without opening the box at each link of the warehouse, and the scanned information is directly related to the distribution place of the wine in the system. After the circulation process from the storage to the distributor is completed, a complete circulation chain of wine will be formed in the system. Therefore, each circulation link of the wine can be traced arbitrarily. If there is a violation of goods, the system will automatically alarm.

3. Anti-counterfeiting method: The laser stitching code is difficult to forge, and the authenticity can be identified by the naked eye; the RFID global unique code can be identified by a handheld scanning device. The relevance of the three codes is also one of the methods of authenticating.

4. Market audit: Before using the product dynamic traceability system, wine companies maintain a large market audit team, and use traditional unpacking and spot checks to monitor the entire logistics process of wine. With this system, it goes without saying that the market audit work has reduced staff and increased efficiency. The most important thing is to “strike” more accurately. In the game with counterfeiters, you can use “data to speak” to ensure that consumers can enjoy the real good. Wine quality.

[ad_2]