Technical solutions for informatization and traceability management of RFID meat processing

[ad_1]

RFID (Radio Frequency Identification) technology is an advanced non-contact automatic identification technology used for meat food safety traceability management. Because of its fast identification speed and high accuracy, it is beneficial to improve the efficiency of information collection in all links of the supply chain; tags are anti-pollution , High and low temperature resistance, strong durability, suitable for the application environment of each link of the meat food supply chain; a large amount of information storage function, to meet the needs of safe information record transmission in each link of the meat product supply chain. As the current domestic application of RFID technology to track management of the meat product supply chain is still in the trial stage, most of it is the application of one or several links. It is difficult to track and trace the entire food supply chain, but the meat product enterprise can be realized first. Internal traceability management.

Project Background

Meat processing is a mixture of discrete and process processing. The deboning, segmentation, pickling, stirring, and filling in the early stage belong to the process processing links, and the later slicing and packaging belong to the discrete processing links. The discrete links of materials and semi-finished products have clear units or packaging, which is convenient for RFID tags to be directly traced; the process links involve the mixing of raw materials and the change of properties, and the individual raw materials and semi-finished products cannot be clearly distinguished. Therefore, RFID tags cannot be used to directly identify materials. Individual tracking, how to apply RFID technology in the process link to maintain the uninterrupted real-time collection of production data and quality tracking is a difficult problem to achieve this type of application. This article proposes to implement the informatization and traceability management of the production process through the use of fine management methods with the application of RFID technology.

Project Introduction

The following takes the processing of smoked sausage as an example to illustrate the application of RFID technology in the processing of meat products to realize the informatization and traceability management of the production process.

The processing process of smoked sausage is as follows:

(1) Raw material inspection: Each batch of raw materials needs to be inspected first after entering the factory. The inspection process includes inspection and registration of relevant certificates such as disinfection, quarantine certificate and five prevention certificates, and random inspection of the raw materials. During the inspection process, fill in the inspection report based on the recorded information, and only after the final assessment is qualified can it be put into the warehouse. The stamped inspection report and the original “three certificates” are archived, and the content of the inspection report is entered into the enterprise production information management platform for subsequent process inquiries.

(2) Raw material warehousing and inventory management: As a batch of raw materials may be purchased in large quantities, there will be differences in the same batch. In order to achieve safe traceability, starting from the raw materials, it is divided into several small batches for fine management. Small batches can be divided according to the feeding capacity per unit time. Each small batch corresponds to containers with UHF band RFID tags, such as trays, for storage. The label and coding rules are in accordance with the national meat product tracking regulations. A fixed UHF band RFID reader and an external high-power antenna are installed at the entrance of the warehouse to automatically record the warehousing information of each batch of raw materials. Inventory management can record and take inventory of the placement position of items through a handheld UHF band RFID reader, which is convenient for item management and search.

(3) Raw material delivery and segmentation and thawing: The production management personnel receive one or several small batches of raw materials with the bill of materials, and the warehouse outlets are installed with fixed UHF band RFID readers and external high-power antennas, and automatically record according to the set function Information such as the time and quantity of delivery from the warehouse are uploaded to the enterprise production information management system. After each small batch of raw materials is released from the warehouse, a corresponding batch card is issued. The batch card is an HF band RFID tag. Its unique ID corresponds to the batch ID of the batch of raw materials in the production information management platform, and the information bound to it is inherited until the warehouse The UHF label information at the exit will be tracked by the production manager holding the batch card for the batch of raw materials in the follow-up link. After each small batch of raw materials has been thawed and divided, it can be recorded through a handheld RFID terminal and uploaded to the information management system. The system will monitor whether the batch of raw materials undergoes subsequent pickling within the specified time.

(4) Intermediate process processing link management: The application of RFID technology in the tracking of intermediate process processing links such as pickling and rolling, stirring and filling, fumigation and cooking, cooling and packaging, and secondary sterilization has been described in the second question answer. Each link is equipped with at least one fixed or handheld HF band RFID reader. From the beginning of the raw material into the pickling link, it enters the process of processing. In this process, RFID tags cannot be used for tracking, but the raw materials can be input in small batches, and the processing progress of the batch of raw materials can be tracked according to the batch ID. At the same time, it is necessary to collect and record quality control related parameters such as temperature and time in different links of each batch. According to different on-site production conditions, DCS can be used for direct collection, handheld terminal collection or manual collection, and the collected data can be uploaded to the production information management system.

(5) Delivery information management and traceability: Before each batch of meat products completes all processing procedures, they need to undergo physical, chemical, and microbiological inspections. If the inspection is found to be unqualified, it will be traced from the production information management platform based on the raw material batch ID. After passing the factory inspection, a UHF band RFID tag can be affixed to the outer large package of the product, and the corresponding quality and safety information of the batch of products can be written into the tag through a handheld UHF band reader. The label and coding specifications for large packages are in accordance with the national meat product tracking management regulations, and the internal small packages are affixed with EAN/UCC standard bar codes. In the user query database, the bar codes are associated with the contents of the electronic labels. In this way, wholesalers and consumers can use label identification or barcode scanning to retrieve quality and safety-related information such as the date of manufacture of the product, the variety of raw materials, and the place of origin. Once problems are found, they can be traced.

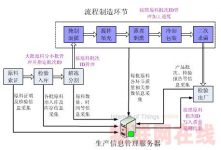

Information collection and management process of smoked sausage processing:

Traceability management process of smoked sausage processing information:

Project significance

In recent years, various meat-based food safety issues have frequently appeared in various countries around the world, such as mad cow disease, avian flu, antibiotic residues, and illegal addition of hormones, which have seriously affected human health. The meat-based food safety problem has become increasingly serious and has become the world’s agricultural and health departments. Important work of close supervision. my country is a major producer of animal husbandry in the world, but its share of the world’s meat food export market is very low. The important reason is the lack of food safety. The root cause of meat food safety problems lies in the development of production industrialization and the continuous expansion of the market. Most meat foods reach consumers through a complicated supply chain; meat foods often change the properties of raw materials in the supply chain, which is difficult. The quality of raw materials is identified by the finished product; coupled with the multi-level processing and circulation links, all have an impact on product quality and safety.

This plan puts forward a technical plan for the informatization and traceability management of RFID meat products processing process, combined with business requirements, designed equipment selection and deployment requirements for applying RFID in each link, and studied key issues in application implementation.

RFID technology is combined with refined management methods to realize internal traceability management of meat products companies, extending to upstream and downstream links, and then realizing effective monitoring and tracking of various links in the supply chain such as feeding, slaughtering, warehousing, transportation, processing, and sales. The realization of the safety traceability management system of the meat food supply chain requires the establishment of a unified safety information platform under the leadership of government departments to collect, summarize and supervise the safety information of all links in the supply chain in a timely manner.

[ad_2]