RFID clothing industry solutions

[ad_1]

RFID technology is used in all aspects of the clothing industry, such as production, distribution, and retail. RFID technology is used to solve the current problems of inaccuracy and inefficiency in data collection and low data utilization in the process of clothing from offline to delivery, and low data utilization to achieve accuracy. Fast product packing, storage, and shipment coordination shorten the supply cycle and improve the production efficiency of the enterprise.

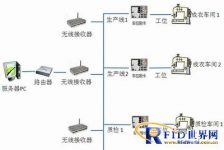

Use RFID wireless identification and collection technology to replace the traditional counting, work ticket, and bar code recording mode of the workshop, breaking through the old framework. It has large information capacity, high real-time performance, diverse functions, fast and convenient operation, reusable, and long-term use Advantages such as low cost. With computer software, RFID readers, and networks, through the operation and recognition of the electronic tags carried on the pieces of clothing that flow to each production process, the entire production process can be monitored and managed in real time, including order execution and completion, clothing production progress tracking and Control, find the bottleneck of the assembly line, control the quality of clothing production, and calculate the wages of workers. Based on the accumulation of previous production information, it can also perform intelligent production scheduling and process improvements on orders to increase production efficiency.

In sorting washing, distribution centers, retail stores, inbound, warehousing, and inventory management, using RFID technology non-visual reading and multi-tag simultaneous reading features, dozens of full boxes of clothing attached with electronic tags are read through RFID The device completes accurate reading at one time, which greatly improves the logistics efficiency.

Key points of clothing assembly line FCL/full set of identification channels

Apparel washing application flow chart

The laundry electronic tag is sewn onto the clothing, and the clothing information is written into the electronic tag to establish an association in the system.

The laundry center monitors clothing with electronic tags.

After the laundry is sorted, it enters the sorting and sorting process. After washing, the current state of the laundry is updated.

When picking up the clothing, check the pick-up slip with the electronic label information, and pick up the clothing after confirming that it is correct.

[ad_2]