RFID fabric library system management solution

[ad_1]

1. Project background

In China’s textile and apparel industry, the consciousness of supply chain transformation has begun. Many companies have relied on the earlier intervention of the supply chain management system to position themselves in the global market and take the road of differentiated positioning and differentiated operations. , Has shown its advantages in the fierce competition. As the world’s largest shirt OEM manufacturer, the Hong Kong Esquel Group has extended its tentacles to the upstream source of the industry-starting from cotton planting, the business covers cotton spinning, woven, knitting, dyeing, finishing and garment making, sales, etc. Link. And they use RFID technology, from cotton picking, processing, to packaging inspection, the production of various places through the Internet timely information communication and visual monitoring, eliminating the time and manpower of manual inspection, its efficiency and market responsiveness are far higher In similar companies. At the same time, many domestic clothing brands are discussing and trying to use RFID technology to solve the increasingly serious problems of anti-counterfeiting/anti-smuggling.

On the one hand, textile/clothing companies are using RFID technology and other information technology due to management needs. On the other hand, government agencies are also working hard to promote the improvement of the information management level of textile/clothing companies. The “Plan” clearly states that the full application of digital technology, information technology and biotechnology is the main direction for the progress of printing and dyeing technology in the “Twelfth Five-Year Plan”.

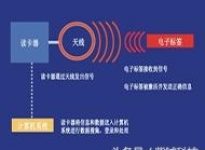

1.1 Introduction to Radio Frequency Identification (RFID) Technology

RFID is the abbreviation of Radio Frequency Identification, which is a non-contact automatic identification technology. RFID can be traced back to the Second World War (around 1940), when the main function of RFID was to distinguish between enemy and British aircraft. In recent years, with the development of large-scale integrated circuits, network communications, information security and other technologies, as well as the promotion of the world’s number one retailer Wal-Mart and the U.S. Department of Defense, RFID has been rapidly applied to smart grids, transportation, logistics, medical and health, Fine agriculture and animal husbandry, finance and service industry, industry and automatic control, smart home, environment and safety inspection, public safety, national defense and military, smart city and other industries and fields.

RFID technology has non-contact, fast scanning, high identification efficiency, not easily damaged, suitable for harsh environments, convenient operation, fast reading and writing, large information storage capacity, one card for multiple uses, anti-collision, good security encryption performance, and repetition Features such as usability, tracking and positioning.

RFID technology is divided into low frequency, high frequency, UHF, active, etc. according to frequency bands. Based on the needs of this project, this project uses UHF RFID (UHF RFID).

2. The overall idea of the system

2.1 Scheme design ideas

Based on years of RFID system integration experience and long-term close cooperation with many internationally renowned RFID product suppliers, Ziyue Technology has fully summarized and refined RFID technology and industry customer business, forming an “architecture-based, customized supplementary, “Business first” RFID management system construction model. That is: through RFID product selection design and construction of a mature and stable system architecture, through customization to meet individual hardware requirements and software systems, through professional business analysis and system implementation service to ensure the success of the project.

1) Hardware solutions based on the world’s leading Impinj UHF RFID products and technologies, and service-oriented SOA software solutions based on the Microsoft .Net Framework framework to build a RFID fabric library management system that meets the requirements.

2) Fully consider and investigate the characteristics of fabric management and the characteristics of e-commerce platforms, and organize the project requirements to design a reliable, easy-to-use, integrated, maintainable, expandable, and manageable system.

3) Promote system construction based on the principle of “overall planning and step-by-step implementation”. The system is built on a unified system framework, the overall business needs analysis is carried out, and the experience is summarized and comprehensively promoted after the steady operation of the pilot.

2.2 System application architecture

The system application architecture is divided into three logical levels: acquisition layer, application layer, and presentation layer.

2.3 RFID management design

2.3.1 Label management

Electronic label management provides functions such as initialization (new creation), verification, query, modification, and cancellation of RFID electronic labels.

The electronic label initialization mainly completes the processing of fabric samples to the warehouse, writes the electronic label code (EPC), prints the electronic label information, binds the fabric label and the fabric, binds the shelf label and the shelf, and verifies the basic work before the circulation of the electronic label. . After recording the basic information of the fabric sample and binding the electronic label to the fabric, the electronic label is pasted on the fabric sample, and the electronic label can be put on the shelf for circulation after the security code of the electronic label is activated. The system provides convenient modification functions, which can modify electronic label information and record the modification in the system. For damaged fabric electronic tags or destroyed fabrics, the system provides the function of canceling electronic tags.

2.3.2 Warehouse management

After the fabric samples provided by the fabric supplier arrive at the center or return the fabric samples out of the warehouse, the fabric samples need to be sorted and executed after the warehouse process.

Interface display

2.3.3 Outbound management

When organizing or participating in fabric-related exhibitions or receiving fabric samples in batches, it is necessary to pack fabric samples to perform the outbound process.

3. Key technology design

3.1 Principles of Technical Design

In terms of technical standards, in accordance with the principle of “unified standards”, UHF RFID products need to comply with EPCglobal UHF Class 1 Gen2 and ISO 18000-6C international standards.

In terms of technical route, in accordance with the industry informatization requirements of the “unified platform”, the system adopts a service-oriented SOA software solution that follows the Microsoft (Microsoft) .Net Framework framework, and uses hardware solutions based on the world’s leading Impinj UHF RFID products and technologies. plan.

In terms of technical architecture, the use of web service-based architecture ideas and multi-layer architecture ideas to guide system design, realize the separation of presentation layer, WEB service layer, business logic layer and data layer, and ensure the openness and scalability of the system from the system structure To establish an informatization application platform that can be assembled and defined according to business needs.

In terms of system integration, data interaction is carried out with the fabric net’s e-commerce platform, so that the data of the fabric library and the fabric net are consistent, and the information is automatically exchanged.

3.2 System deployment architecture

3.3 Hardware equipment selection

The main hardware configuration list of the system

Note:

1) The hardware configuration estimated based on 50,000 fabric samples.

2). It is assumed that the host server and database software deployed by the system are provided by the center.

[ad_2]