RFID Laundry Management Information System

[ad_1]

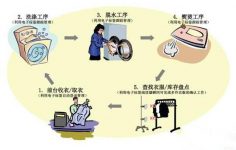

In order to improve the efficiency of laundry work and solve management problems that could not be achieved by other technologies in the past, such as: large quantities of laundry statistics and handover, the use of “RFID Technology Laundry Management Information System”RFIDRadio frequency identification technology makes the laundry management of users more transparent.

【System Overview】

RFID technology laundry management information system, through sewing a RIFD UHF silicone laundry tag on each piece of clothing, the electronic tag has a unique identification code, that is, each piece of clothing has a unique management identification, until the clothing is scrapped (tag Can be reused, but does not exceed the service life of the label itself). In the entire clothes use and washing management, the clothes use status and washing times will be automatically recorded through the RFID reader. It supports batch reading of labels during washing handover, making the handover of washing tasks simple and transparent, and reducing business disputes.At the same time, by tracking the number of washings, it can estimate the service life of the current clothes for the user and provide forecast data for the purchase plan

【System Features】

● Long-distance data collection is adopted, and the number of clothes and related information are counted in time when clothes are handed over;

● No need for manual re-entry, reducing manual operation errors, saving working time and simplifying the work process;

● Improve work efficiency, improve the company’s laundry management supply chain, and save 20%-25% of work service time;

● Through complete system management, realize the information visualization management of the entire laundry management process, which is convenient for enterprise management;

● Reduce the overall operating cost of the enterprise;

● Adopt advanced RFID technology to take a leading position in the industry and enhance the competitiveness of the industry.

【System Details】

● ?Label sewing

The RIFD UHF silicone laundry label can be sewn on the clothes to be managed through a small cloth bag or directly. It is recommended that the sewing position be uniformly selected as a fixed position.

● ?Data entry

The chip in the RIFD UHF silicone laundry tag can store data, associate the attributes and electronic tag ID of each laundry to be managed into the database, and record and track the workflow and life cycle of each piece of clothing.

●? Dirt inventory check

The dirt sewn with the electronic label is directly packed. The RFID tunnel reading device automatically collects the quantity, and records the ID of each piece of dirt read. Since the data is not counted manually, it improves work efficiency on the one hand, and also brings convenience to the laundry work and provides high-quality services.

●? Clean clothes inventory

After the clothes are clean, read the equipment through the RFID tunnel again to check and check whether there are any missing clothes during the washing process, and print out the records for handing over to the user.Clothes sorting and sorting

With the help of the uniqueness of the electronic tag, it can help the clothes in the sorting area, and the RFID reading device can be used to confirm whether there is any misplacement before packing.

[System hardware composition]

1. RIFD UHF Silicone Laundry Tag

2. RFID system workbench

3. RFID Handheld

4. Server (standard configuration dell, the brand can be changed according to customer needs, or the customer’s existing server can be used)

“RFID Technology Laundry Management Information System” adopts independent system software research and development technology to ensure the applicability and aesthetics of the system, ensuring that enterprise users can master the application method of the system in a short time, and deal with minor problems that occur during normal operation. The maintenance rate of the system is very low, which greatly reduces the cost of working time and capital of the enterprise. System functions can be customized and developed according to customer needs, flexible, diverse and humanized management.

[ad_2]