Wireless Zigbee warehouse positioning guide entry and exit system solution

[ad_1]

1. Introduction

The traditional warehouse warehousing management only relies on the warehouse manager’s brain to remember the location of various materials in the warehouse. When warehousing, it will take time and energy to encounter too many materials, and it is easy to place the materials in the wrong position. It is easy to get the wrong materials when leaving the warehouse and cause losses. This method is not only time-consuming and laborious, but also a waste of cost. For this reason, Shangji Electronics has developed a new set of fast, convenient and effective warehouse positioning and guiding system.

The warehouse positioning guidance entry and exit system is developed on the basis of the 629RW RFID wireless terminal device of Shangji Electronics. The 629RW wireless terminal device is a terminal device with display, wireless Zigbee communication, and can be directly operated by buttons. Provides a middleware interface, which can be used in conjunction with any software. The three major functions of display, menu, and data input are added, which are more intuitive and easy to operate.

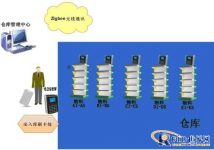

2. System structure diagram

Figure 1: System structure diagram

3. Technical parameters of 629RW wireless terminal equipment

Picture 2: 629RW wireless terminal equipment

Specific performance indicators:

Fourth, the warehouse in and out process

1. Material storage process

(1) The latest materials purchased by the purchasing department must be registered in the warehouse management center before they can be put into the warehouse. First, all purchased materials are registered in the warehouse, including the name, model, quantity, location and other information of the material.

(2) The warehouse management center distributes the material warehousing card, which contains the information of all the latest purchased materials, including the name, model, quantity, location and other information of the material.

(3) Swipe the warehouse card on the 629RW machine at the entrance of the warehouse, transfer the task to each 629RW in the warehouse through wireless transmission, and control the corresponding lights to turn on, that is, the lights corresponding to all materials that need to be stored in the warehouse are on.

(4) According to the position where the light is on, place a certain A material in the x grid on the x counter in the x area of the warehouse.

(5) After placing the A material, swipe the material warehousing card on the 629RW that controls the corresponding A material light, that is, the light corresponding to the A material is off, indicating that the A material has been put into the warehouse. At the same time, the LCD display of the 629RW machine displays: How many materials are left unstocked, and prompts the specific location of the unstocked materials, such as: 1-2-2 (representing zone 1, counter 2 and floor 2) (you can set the display mode by yourself) )

(6) Place the corresponding materials on the corresponding lights in turn, until all materials are put into the warehouse and all the lights are off.

2. Material delivery process

(1) When each department picks up materials from the warehouse, they need to apply to the warehouse management center for the delivery list of the required materials

(2) The warehouse management center sends out a KU card, which contains all the information of the materials requested for delivery, including the name, model, quantity, location and other information of the materials.

(3) Swipe out the library card on the 629RW machine at the entrance of the warehouse. Through wireless transmission, the lights corresponding to all the materials that need to be picked up will be on.

(4) According to the position where the light is on, take out the B materials that need to be picked up in the X grid on the X floor of the X counter in the X area of the warehouse.

(5) After the material B is taken out, swipe the card on the corresponding 629RW and the light will go out, indicating that the material B has been taken out. At the same time, the LCD display of the 629RW machine displays: Where is the specific location of the material, such as: 1-2-2 (representing area 1, counter 2 and floor 2) (the display method can be set by yourself)

(6) Pick up the corresponding materials at the corresponding lights in turn, until all the materials are out of the warehouse, and all the lights are off.

3. Flow chart of warehouse entry and exit

Figure 3: Flow chart of warehousing

Figure 4: Flow chart of outbound

[ad_2]