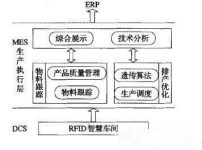

Based on ThingMagic UHF RFID handheld terminal to MES smart factory system

[ad_1]

MES can provide users with a fast-responsive, flexible, and refined manufacturing environment, helping companies reduce costs, deliver on time, improve product quality and improve service quality. It is suitable for different industries (home appliances, automobiles, semiconductors, communications, IT, medicine), and can provide good enterprise information management for single mass production and mixed manufacturing enterprises that have both small batch production and mass production of multiple varieties.

The data collection function in MES is responsible for collecting various necessary real-time updated data information in the production site and providing data sources for data management of other MES functions. As a means of data collection and management, RFID technology is entering the core of the manufacturing process from the supply chain. MES can make full use of the characteristics of RFID and install RFID data collection terminals on complex workshops.Based on ThingMagic UHF UHF RFID module, whether it is integrated fixed UHFRFIDReaders, or integrated portable UHF RFID handsets, are suitable for complex workshop environments.

The combination of RFID and MES is to run RFID technology through the entire production process, and conduct all-round and full-process visual tracking of feeding, processing, packaging, transportation, and storage:

1. Quality management

RFID can provide continuously updated real-time data to ensure the correct use of labor, machines, tools, and components, thereby achieving paperless production and reducing downtime to ensure reliability and high quality.

2. Product tracking

As long as the part enters the production line or arrives at the completion area, information such as procedures, equipment, and operators will be automatically recorded to achieve a comprehensive tracking from raw materials to the final product, and avoid data errors caused by manual entry.

3. Planning and scheduling

For example, the RFID on processing equipment such as machine tools provides operating time, availability status, performance characteristics, and contains technical parameters, production activities that have been carried out, etc., so that real-time planning and scheduling in the workshop can be carried out in accordance with the utilization rate of the existing equipment in combination with the product process specification. Procedure.

4. Equipment management

The operator can check the equipment and its location by reading the information on the label, maintain or repair the equipment, and then write the latest data to update the RFID label, which is helpful to improve the value of the equipment, optimize the performance of the equipment, and maximize the utilization of the equipment Rate.

By gradually adopting RFID technology at the workshop level, the information captured from RFID can be seamlessly and uninterruptedly integrated and linked to the existing control system infrastructure, coordinated with the supply chain equipped with RFID functions, and fully utilized the MES close to the bottom to schedule production The advantage of sending accurate and reliable real-time information stream, improving production efficiency and greatly saving investment. If your factory has implemented an MES system and want to better improve its efficiency, quickly pick up the phone and consult on the application of RFID technology:

[ad_2]