Foxconn Mold Management System Solution

[ad_1]

1. System introduction

Traditional mold management uses paper-based registration of mold numbers and position numbers, which can easily cause registration errors, loss of records, management confusion, and extremely inconvenient search. This system uses RFID Internet of Things application technology to realize rapid warehousing and inventory management; through the back-end database, realizes rapid search for molds; scientifically and systematically manages molds.

This system has the following advantages:

The RFID electronic label is attached to the mold, which is stable, safe and reliable;

Use RFID electronic tags to systematically encode and identify the molds to realize quick access to and storage of molds and inventory management;

Can specify molds for quick search operations;

A database system for real-time recording of mold usage and maintenance conditions.

2. System workflow

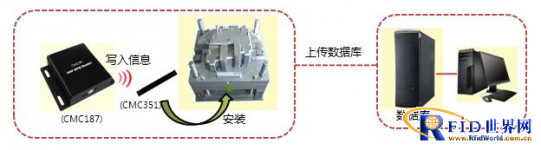

1. RFID tag writing information and installation

Write information: The tags use ultra-high frequency anti-metal tags (CMC351), each tag is assigned a unique ID number, which corresponds to the mold one-to-one, and writes the mold information into the chip, including: mold number, production date, mold location, Upload the database for mold types, processing materials, repairs, maintenance, etc.;

Installation: The surface of the label is made of high-strength engineering plastic, which is resistant to pressure and impact. Install an anti-metal label on each of the four sides of the mold.

2. Mold storage management

Storage: Read the anti-metal tag (CMC351) of the mold through the UHF antenna (CMC330), the active RFID reader (CMC191) automatically reads the elevator tag (CMC362) of the mold rack, and the system automatically binds the mold position , Upload data to the back-end database through the industrial control computer (CMC812A) to realize fast storage;

Outgoing: Read the anti-metal tag (CMC351) of the mold through the UHF antenna (CMC330), the active RFID reader (CMC191) automatically reads the elevator tag (CMC362) of the mold rack, and the system automatically releases the position of the mold. Upload data to the back-end database through an industrial computer (CMC812A) to achieve rapid delivery;

Inventory: Check the inventory of molds in time through the database system to understand mold inventory.

3. Mold query management

Query: Enter the number of the mold to be searched in the system, and the system queries the elevator tag (CMC362), and its corresponding identification position, so as to realize the quick search of the mold.

4. Mold repair and maintenance management

Repair and maintenance: In daily repair and maintenance, the repair and maintenance records are entered in time through the handheld reader (CMC165) and uploaded to the database system through the wireless module in time. Through the real-time recording of the mold’s use and maintenance conditions to the database system, it helps the management analyze the reasons for the loss of the mold and evaluate the life of the mold.

[ad_2]