Process solutions for garment manufacturing enterprises

[ad_1]

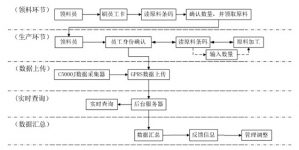

At present, the manual piecework system is adopted. There are 22 production processes, and the front-line staff of each process go to the designated workstation to receive the designated amount of raw materials with the job number, and then return it to the workstation after finishing. The workstation staff manually register the job number and the number of products made, and then summarize them to the data entry personnel, and these data entry personnel enter the company’s computer management system; the financial personnel conduct the salary and performance assessment of the employees.

The traditional work process is faced with unfavorable factors such as a large amount of data manually entered by the staff, a lot of wrong data, and low production efficiency. The application of barcode/RFID+GPRS technology can realize real-time data management of the production line, which not only solves the problem of inputting the production volume of employees, but also meets the needs of online production scheduling.

Improve data accuracy, accurate employee performance appraisal; improve production efficiency, and allow employees to exert greater work abilities in limited working hours.

【instructions】

1. The picker picks the material:

The picker confirms the identity: use the handheld to read the picker’s IC card;

The picker picks: Use the handheld to read the barcode of the material, confirm the quantity of the raw material and related information;

2. Production process:

Confirm the employee card at each station; record the amount of raw materials received by the employee and related information; use the handheld to record the recipient and the material bar code; after the employee finishes the raw material processing, before starting the second raw material collection, read the raw material bar code to The end of the display; enter the next process.

3. Data summary:

Real-time upload of relevant information to the back-end server via GPRS; management personnel can query data; check the processing progress of each station employee at any time; check the quantity and other information made by each employee.

【System functions】

According to the above process, the data collector software contains the following three functions:

1. Process management system

Process management for each process through the data collector (C5000J type). Use the data collector (C5000J type) to read the employee card and bar code to record the employee ID and the number of employees, and then transmit it to the background server through the GPRS communication of the data collector (C5000J).

2. Data upload system

The data collection results in the picking and production process are uploaded to the background server through the data collector (C5000J type) GPRS communication method; at the same time, the relevant data can be saved. If there is no signal or upload failure on the communication network, it can be transmitted again by wired or wireless means.

3. Real-time information system

In the process of data collection, the manager can perform real-time monitoring through the background data collection situation, and perform related personnel scheduling according to the needs of production. The scheduling information is downloaded through the GPRS communication of the data collector (C5000J type). Relevant information can be viewed on the data collector (C5000J type).

[ad_2]