RFID-based smart manufacturing solutions

[ad_1]

The manufacturing industry faces many problems

1. Large amount of data collected in production, low manual input efficiency, large errors, and unreliable data

2. Insufficient production schedule monitoring, inaccurate control, and poor controllability

3. The data from order production to workshop work-in-process and completion are not clear, and the cost cannot be calculated accurately

4. Product quality loss is serious, the repair rate is too high, and quality traceability cannot be carried out

5. Data statistics cannot be updated in real time, business information is asymmetrical, and it is difficult to guide future production plans

6. The lack of a flexible and effective decision-making analysis platform makes corporate management difficult.

RFID-based intelligent manufacturing

Intelligent manufacturing aims to integrate the knowledge and experience of experts into manufacturing activities such as perception, decision-making, and execution, and endow product manufacturing with the ability to learn and evolve knowledge online to achieve high-quality manufacturing. Its key technologies include intelligent perception technology (RIFD, sensors), artificial intelligence technology, intelligent drive technology, intelligent numerical control technology, intelligent logistics technology, etc.

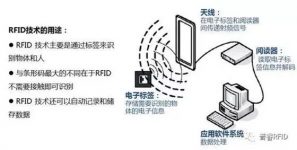

RFID radio frequency automatic identification technology

RFID is an advanced non-contact radio frequency automatic identification technology, which has the advantages of long identification distance, fast speed, strong anti-interference ability, and simultaneous identification of multiple targets. In addition, RFID tags have the advantages that bar codes do not have, such as: waterproof, anti-magnetic, high temperature resistance, long life, long reading, data can be changed, encrypted, large storage capacity, etc.

RFID-based smart manufacturing solutions

Purui Technology’s intelligent manufacturing solution realizes and strengthens the autonomy and self-optimization of products, machines and people by establishing connections between products and machines, machines and machines, and humans, thereby significantly improving production efficiency and production flexibility. At the same time, smart products manufactured by Industry 4.0 can be connected to the Internet through the Internet of Things technology, and the application of big data and other IT technologies can transform the business model of enterprises from product-driven to data-driven, and from selling products to Selling services, enhancing and improving the user experience, thereby realizing the innovation of business models.

1. Realize automatic identification and real-time management of work-in-progress:

2. Realize real-time tracking of product life cycle:

3. Improve the work efficiency and service level of enterprise production management

Wide range of applications:

System advantages:

1. Realize multi-variety mixed-flow assembly, automatic process data collection, and increase the data collection rate to 99%;

2. Realize tool life management, increase service life, effectively reduce processing equipment preparation time, increase machine tool utilization, and reduce tool inventory by 20%;

3. Reduce material inventory by 20%; improve distribution efficiency and accuracy by 30%; increase resource utilization rates such as forklifts and AGVs by more than 50%.

[ad_2]