RFID mobile application solution for steel industry

[ad_1]

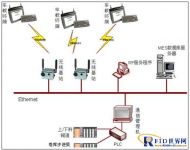

Through wireless vehicle-mounted terminal and handheld terminal, and real-time data transmission of MES, combined with barcode andRFID Technology to realize mobile operations on the work site and effectively improve production efficiency.

The current production and operation environment faced by the iron and steel industry is changing, and the market competition faced by iron and steel enterprises will be very fierce. In order to reduce inventory and save costs, the most effective operation strategy is to change the traditional push system with forecasting as the main axis to a pull system with demand planning as the main axis. Under this production mode, the sales department and production planning department of the enterprise Both put forward higher requirements.

In response to the informatization requirements of the steel industry, Node.com can provide multi-faceted solutions, including:

• Wireless Warehouse Management System

Used in semi-finished products, finished products warehouses and spare parts warehouses, through bar codes and electronic tags, automatic data collection and on-site data processing of the warehouse’s daily operations, real-time stacking management, automatic collection of coil numbers, and heat numbers, and steel The factory’s MES system or ERP system realizes interface connection to provide timely and effective data.

• Crane positioning and wireless operating system

Equipped with a vehicle-mounted terminal in the crane’s cab, directly connected to the MES system through a wireless network, the crane can obtain operation tasks in real time, and position the x, y, and z axes during operation to assist the driver in correct operations.

• Stockyard wireless networking

Provide a wireless real-time networking solution for the stockyard, which can remotely monitor and control the reclaimer and unloader. It only needs to set up a wireless base station to realize the wireless networking of all stockyards and realize real-time monitoring.

• Vehicle management

Use RFID to realize effective management of vehicles entering and leaving the steel plant, and realize the management of weighing, sampling, sample preparation, unloading, and peeling after the vehicle enters the plant. The staff can use the handheld terminal to read the RFID card at any time It also transfers the read information to the data center in real time to provide management methods for the path, process and time of the vehicle after entering the factory, and improve the level of vehicle management in the steel plant.

[ad_2]