RFID steel plate offline process automation management system solution

[ad_1]

1. General overview

OneRFID steel plate offline process automation management system, mainly for automatic extraction of steel plate information and automatic location of steel plate information between steel plate production and steel plate storage, and visual management of the process. Its core is the automatic collection of steel plate information at process nodes. Reasonable allocation of storage locations, the application of Internet of Things technology to realize the overall solution of steel plate process automation management.

system integrationRFIDTechnology, automatic identification technology, wireless communication technology, in the whole process of steel plate circulation, automatic and reliable data collection, automatic discrimination, automatic processing, and automatic control are achieved, which minimizes the drawbacks and work intensity caused by manual operation and improves The degree of integration, informatization and automation of the system.

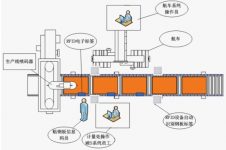

2. Overall framework diagram

Three, the existing problems

The steel plate offline process management is still in the semi-manual and semi-automated management stage, and the process control from the completion of the steel plate processing to the storage is a blind spot of information and cannot be effectively monitored;

The degree of automation is not high, which increases the operating cost of the enterprise and reduces the operating efficiency;

Many manual interventions, high error rates, and untimely informatization make the profile easy to hang wrong, and the model and weight are not compatible, which directly brings economic losses;

Manual intervention cheating exists, and the board cannot be traced;

Fourth, the problem to be solved

Steel plate off-line: system productionRFIDThe label corresponds to the information of the steel plate and is pasted;

Steel plate positioning: through the installation of RFID equipment on the production line, the steel plate is identified and positioned, and the aviation personnel are notified of the hoisting.

Steel plate warehousing: Identify the steel plate label information through RFID equipment, and the data is automatically transferred to the aviation system. The aviation system worker clicks to confirm and lifts the steel plate to place the system at the designated position;

To find goods, the staff scans the steel plate label through the handheld device to quickly find a certain steel plate from the stockpile;

MES interface, through the interface with the MES system, the inbound and outbound data information is directly imported into the MES system to achieve real-time increase and decrease of inventory;

[ad_2]