Smart factory management solution based on RFID and ZigBee

[ad_1]

1What is an intelligent production line management system?

The survival and development of traditional manufacturing industry is inseparable from production. Therefore, how to manage the production line intelligently and efficiently is a problem that business managers must consider. The intelligent production line management system can be composed of RFID card, wireless terminal equipment (using ZigBee module), ZigBee serial server (ZBCOM-300IE), LED display and PC, enabling the management of the enterprise to grasp the operating status of the production line in real time.

The management system mainly consists of two parts: an information acquisition system with RFID card as the core, and an information transmission system with ZigBee wireless communication as the core.

2 Information Collection System

RFID technology, also known as radio frequency identification, is a communication technology that uses radio signals to identify specific targets and read and write related data. The communication process does not require mechanical or optical contact between the identification system and specific targets. At present, in the traditional discrete manufacturing industry, compared with the widely used barcode technology, RFID technology can read and write long-distance, can read and write and store a large amount of data under high-speed movement, and can read and write penetratively. Can be used in harsh environments.

The acquisition system first bundles the semi-finished products in the production workshop and the identification code of the workshop workers through the RFID card. The worker reads the information entry system on the RFID card after completing a process, which can monitor the progress and flow of each batch of goods in real time. .

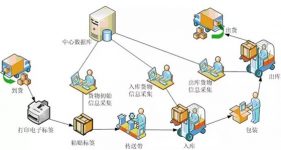

Figure 1 Intelligent management of production line

Figure 2 Flow chart of the information collection system

3 Information Transmission System

The information transmission system consists of two roles: ZigBee terminal node module and concentrator (gateway). Each station is equipped with a ZigBee wireless terminal, and a concentrator connects 50 to 100 terminal nodes, which can be used to run the station. Information such as status is transmitted to the background server in real time. The concentrator and the background can be connected via RS-232 or Ethernet.

In the background control room, the administrator can connect to the server through a PC, and then judge the completion of the products in production and the operation of each station. The system flow chart is shown in the figure below.

Figure 3 ZigBee information transmission system

The advantage of the wireless information transmission system is: it can save the trouble of early-stage wiring and post-maintenance of the factory, and save wire costs; real-time statistics of workers’ output, efficiency, piece rate, cargo tracking, quality monitoring and delivery control, easy Realize visualized production and intelligent management, thereby improving product quality and production efficiency.

[ad_2]