Mulan Vehicle Intelligent Weighing System Solution

[ad_1]

System requirements overview

In some large domestic public enterprises and institutions, such as power plants, coal yards, garbage dumps, etc., a large number of material transportation vehicles enter and exit every day, and procedures such as parking, registration, and weighing are required in the process of business processing. At present, these units mainly rely on operators to manually enter data into computers. Manual operation is not only time-consuming, but also has a large error rate. In addition, a weak control environment can easily breed man-made fraud and cause a lot of economic losses to enterprises and institutions. With the rapid advancement of national economic and social construction, this manual-operated work method has gradually been unable to meet the ever-increasing business processing requirements.

AWS (Auto Weighing System) is an intelligent vehicle weighing system, which is an intelligent synthesis that combines weighing systems, access control systems, LED large-screen display systems, video surveillance systems, and parking lot automatic control technology with long-distance RFID radio frequency identification technology. Management system. The system uses electronic truck scales, long-distance RFID radio frequency equipment, automatic barriers, signal lights, etc. to integrate into an intelligent system, which can automatically record the ID number, weight, time, unit and other information of vehicles entering and exiting, and directly write them into the host database. The host can transmit data to the monitoring computer in real time, and the monitoring computer can also call the data in the host database at any time. The AWS system plays a huge role in improving the efficiency of cargo transportation and handling, making the business management model more structured, standardized, and scientific, thereby improving the management level and reducing costs. As the vehicle information (front-end) collection tool of the AWS system, long-distance RFID technology can significantly increase the passing speed, and through automatic identification of vehicle number and anti-disassembly measures, it can effectively prevent human fraud from bringing economic losses to enterprises and institutions. In addition, the intelligent weighing system based on RFID technology can also greatly reduce the labor intensity of the staff and the error rate of manual weighing, and improve the transparency of the vehicle transportation management process. At the same time, it is possible to realize the designated route for the vehicles in the factory area and supervise the vehicles.

At present, the AWS system that has been put into operation in China mainly adopts passive (passive) RFID technology. This is mainly related to the low cost of passive vehicle tags, but the short recognition distance of passive technology, unstable reading and writing, and small memory space available for passive tag cards have been severely restricting the efficiency of the system. Most source tags cannot tolerate harsh working environments. RF signals are extremely unstable when exposed to rain, snow, or dust. The typical application environment of the AWS system is precisely the harsh working environment such as coal yards and garbage dumps. Several projects based on passive technology in Inner Mongolia, Hebei, Shanxi and other places have successively encountered one or even several of the above problems. Therefore, the industry has gradually turned to active RFID suppliers to seek technical and product solutions. plan.

Program overview

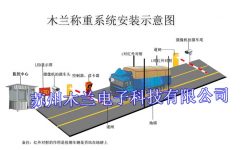

Relying on the deep technical foundation in the field of active RFID, Suzhou Mulan Electronic Technology Co., Ltd. SuperRFID technology has gradually launched highly targeted products and applications in the field of intelligent vehicle management, and has received great welcome from the market. Application is one of them. The schematic diagram of the intelligent weighing system based on RFID technology is as follows:

The system workflow is as follows:

• The entrance barrier is lifted, and the weighing vehicle enters the lane. After the vehicle enters the lane, the entrance barrier is lowered to prohibit the next vehicle from entering the lane.

• The vehicle passes through the entrance induction coil in front of the barrier to generate an induction signal. The remote reader reads the electronic tag information on the vehicle, uploads the tag information to the host database, and retrieves the vehicle information at the same time. (If the tag uses a general vehicle electronic tag, multiple tags may be recognized at this time, and the operator needs to manually select the information of the current weighing vehicle on the software. If the dual-frequency electronic tag is selected, only one vehicle’s information will appear. information)

• 2 pairs of infrared beams detect whether the vehicle is directly above the weighbridge. If the vehicle is standing, the vehicle will be weighed on the scale, the display will display the weighed weight information, and the vehicle image information will be captured at the same time.

• After the weighing is completed, the vehicle is weighed down, and after passing the ground induction coil buried behind the exit barrier, the exit barrier is released by lifting the rod.

• After the vehicle is released, the exit barrier will be closed at the same time the entrance barrier will be lifted, allowing the next vehicle to enter.

• According to the actual situation, after identifying the vehicle number information, the automatic barrier lifts the lever, the vehicle is weighed, and the automatic barrier is closed to prevent the next vehicle from being weighed.

In the application of the system, the electronic tag is generally installed on the inner side of the front windshield of the transportation vehicle, and the sensing distance from the long-distance reader is usually 5-15 meters. In order to better handle the related services carried by the information of the carried materials, the system generally requires tags to have a larger data capacity. At the same time, to prevent internal fraud, once information is written into the tag, it is required that the internal information of the tag cannot be illegally tampered with. On the other hand, in order to prevent the vehicle from over-licensing, the label can be installed without disassembly: once the installation is completed, the label can no longer be effectively used after being disassembled without legal authorization.

Program features

• Simple structure, convenient debugging and installation, wide weighing range and strong adaptability

• It can transmit information over long distances, can carry out remote control and group control, so that the system can be truly automated and intelligent, and can be networked with a computer to automatically analyze, calculate and print data records and reports

• Convenient installation and maintenance, no need for excavation and construction, and less damage to the road surface. If the detector is damaged, you only need to replace it as a whole without checking the circuit.

• High reliability, working temperature -40℃~85℃, waterproof and shockproof; vehicle number recognition accuracy can reach 99.99%, suitable for various harsh environment applications such as wind, snow, rain, and fog;

• High anti-interference: There are no special requirements for various interference sources on site, and the installation is convenient and simple.

• There is no need to apply for and pay for the globally open ISM microwave frequency band.

• Ultra-low power consumption: safer and healthier for the human body.

• Completely automated (no human intervention) collection to ensure the accuracy of raw data collection;

• By realizing automatic measurement, the operation time of each operation link can be greatly shortened, the connection and unloading capacity of the measurement system can be improved, labor intensity can be reduced, and labor costs can be saved;

• The data in the label is highly confidential, and the electronic label cannot be forged or copied, which fundamentally eliminates the phenomenon of copying, forgery, and cheating;

• The automatic collection speed is fast, which can realize fast weighing, improve the efficiency of weighing, and avoid the phenomenon of queuing overbalance;

• Plug the loopholes in human operation. Due to the method of automatically reading data, all over-balanced vehicles are automatically counted by the computer, eliminating manual intervention, automatically recording data, and automatically verifying and releasing;

Recommended Products

1. 2.45G long-distance active identification card ML-T80 ML-T801 ML-T125B

2. Long-distance reader (card reader) ML-M2000DX series

[ad_2]