Oilfield and oil well measurement and control scheme based on zigbee technology

[ad_1]

1. System overview

We know that oil wells are the smallest production unit in an oil field. Large and small oil fields are composed of hundreds or thousands of oil wells that are tens of meters to hundreds of kilometers apart. Real-time mastering of various parameters of oil wells and understanding of the operating conditions of oil wells are essential for safe and efficient production in oil fields. The traditional manual collection of these data is inefficient, unable to be accurate and timely, and poses a great threat to the safety of the staff. Later, with the development of technology, methods of collecting these data using GPRS, GSM, and digital radio emerged. However, many problems have been discovered through the use of some oil fields. The first is that these equipment are expensive to build, and maintenance and operating costs are high. The emergence and maturity of ZIGBEE technology is a good solution to these problems. It will surely make the wireless monitoring of oil wells like a bright road.

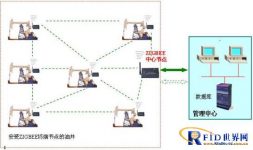

The system is mainly composed of oil field monitoring center and oil well wireless telemetry remote control host, sensor, motor control and protection device, etc. The communication part adopts ZIGBEE wireless network transmission;

The oil field monitoring center is generally set up in the mining department, team department or other monitoring and dispatching department, including the management computer, the central node of the ZIGBEE network; the oil well working status sensor mainly includes temperature sensors, voltage sensors, motor current sensors, and the monitored switch is off/ With sensors, they transform the working state of the oil well into the corresponding voltage or current value and send it to the remote intelligent wireless RTU through the ZIGBEE communication module.

The oil well monitoring system based on the wireless sensor network of 802.15.4/zigbee technology uses a large number of sensor wireless networking transmission methods, completely abandoning the traditional single-use GPRS, GSM, digital radio monitoring method of oil wells. The large investment in equipment, high operating costs and high maintenance difficulties have been completely resolved. The stability of the system is greatly improved, the construction is convenient, and the wireless in the oil well site is realized.

2. System application

1. Oilfield and oil well measurement and control

2. Remote pump station measurement and control

3. Remote data collection

4. Remote monitoring

Three, application principle

According to the distribution law of oil wells, the system adopts ZIGBEE technology combined with other wireless technologies. Since oil wells are generally distributed in groups, there are not many cases where a single oil well is far apart from other oil wells. A wireless network is composed of ZIGBEE terminal nodes, routing nodes, and coordinator nodes in the well site and in the well group. The data of the entire well group is then transmitted via GPRS or GSM back to the data center and user units far away from each other.After data processing in the data center or user unit, the oil wells are constantly monitored

The utility model relates to a pressure detection device, in particular to an oil field wireless telemetry oil well and water well pressure itinerant detection device. The device includes an intelligent pressure collector with wireless transceiver function installed at the wellhead and a handheld patrol instrument that displays and stores pressure and other information. The utility model is powered by an internal battery, and performs pressure detection that can identify the well sign and collect data with time information through wireless communication. Using this device, it is not necessary to open the anti-theft box when detecting the pressure, and the pressure can be read wirelessly outside the anti-theft box or the anti-theft cover. The test is safe and convenient, greatly reducing labor intensity, effectively improving the quality of well inspection, and prompting inspectors to meet the specified requirements. Time, determined oil and water well positions to obtain actual, useful, and accurate pressure detection values are conducive to ensuring the accuracy of basic analysis data, formulating targeted and reasonable control measures for the oilfield production process, and providing a basis for increasing production measures , To promote the production of oil fields.

In my country’s oil fields, whether in water networks, deserts, plateaus, or severe cold areas, the data collection of oil wells is basically done manually. Regardless of the summer heat or snow and dry weather, oil producers must go to the site to collect oil well indicator diagrams, balance degrees, and oil jackets. Wellhead production data such as pressure, oil temperature, and liquid production volume, workers are labor intensive, and the accuracy and reliability of the data completely depends on the work responsibility of the oil production workers. The production management of offshore oilfields is even more difficult, often relying on huge gathering pipelines and adding oil production platforms to reduce the difficulty of on-site management. The production parameters of oil production wells are often affected by weather changes and vehicles and cannot be obtained normally, which seriously affects the oil wells. Automated management. The application of the oil well remote monitoring system is of great significance for realizing the automation of oil well management, improving work efficiency, ensuring the accuracy of data collection and strengthening the emergency handling of on-site accidents.

In recent years, various data acquisition systems and monitoring systems have been widely used in oil field production. Accurate collection, reliability, and ease of maintenance of oil well remote monitoring system data have become the key to restricting the normal and reliable operation of the entire system. At present, load sensors, angular displacement sensors (or pulse generators), monitors, Electrical parameter sensors, etc., are installed on the rope suspension, walking beam and control cabinet respectively, and each signal is collected to the monitor in a wired manner.

Digi’s wireless remote zigbee system integrates advanced and mature computer, communication, data acquisition and sensor technology. Through high-precision data collectors, it can be installed in oil wells, joint stations, transfer stations, water injection stations, metering stations, The current, voltage, temperature, pressure, liquid level, flow rate, water content and other data on the oil production equipment such as the water distribution room are uploaded to the oil field’s local area network through the wireless network to achieve a comprehensive monitoring system for the oil production process. The system has data detection and data Functions such as sharing, data display, auxiliary analysis, alarm, permission setting, etc.

Using wireless technology as the communication method between the sensor and RTU, the sensor, transmitter, MPU controller and wireless transceiver module are combined to form an integrated micro-power wireless intelligent network sensor to realize wireless collection of production parameters.

Network structure diagram

Fourth, the main performance

802.15.4/zigbee wireless network, exempt from radio application license;

Wireless coordinators, routers, bridges, and temperature measurement terminal products with independent intellectual property rights;

Maximum network connection capacity: 65,000 nodes;

Support star, tree, and net network topologies;

The wireless communication distance in an open line-of-sight environment is 600 meters;

Each oil well can be composed of different numbers of nodes according to different monitoring parameters;

Each oil well group can be composed of no more than 65,000 nodes;

Five, system composition

1. Local area wireless transceiver module

2. Wireless indicator diagram tester

3. Wireless analog sensor

4. Wireless RTU

Six, system characteristics

1. High degree of system integration

2. Mature technology

3. Easy to install

4. Zigbee communication does not require any fees

[ad_2]