RFID coal mine personnel positioning system solution

[ad_1]

I. Overview

The use of RFID coal mine personnel positioning system in the field of coal mining and enterprises can effectively solve traditional production and safety issues. Because coal mines have serious hidden dangers of insecurity, endangering the safety of production. According to the working environment of the coal industry,RFIDThe management system can be applied to the entire work process of coal mine production to achieve functions such as mine target positioning and tracking, staff attendance operations, environmental monitoring, restricted area alarms, and digitization of coal mine management information.

2. System background

Safe production in coal mines is the guarantee of the benefits of coal mine enterprises, and it is also an important condition for the continuous and healthy development of coal mine enterprises. In recent years, coal mine safety production has generally stabilized and improved. However, the monitoring of underground personnel by the coal mine safety management department is not perfect. The information communication between ground and underground personnel is not timely, and it is difficult for ground management personnel to grasp the operation and distribution of underground personnel in real time. If an accident occurs, the safety and rescue work efficiency is low, the search and rescue effect is poor, and the safety production situation is still not very optimistic. The location technology of coal mine personnel based on radio frequency identification (RFID) is the most effective way for safe production in the coal mine industry and improving corporate efficiency.

3. Scheme design

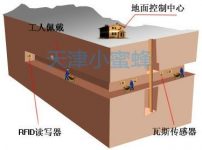

The system consists of a downhole data acquisition and transmission unit, a surface control and management unit, and a data transmission network module. The downhole data acquisition module is the core of the system, which is composed of identification cards, monitoring sub-stations, antennas, sensors, etc. The monitoring substation sends the encrypted data carrier signal through the transmitting antenna, and the identification card carried by the underground personnel enters the working area of the transmitting antenna and is activated (the identification card does not work if it does not enter the working area of the transmitting antenna), the encrypted target is identified The information of the code is transmitted, the antenna receives the carrier signal sent by the identification card, and the substation is processed, and the target identification code is extracted and sent to the ground monitoring computer via the data communication network to complete the automatic attendance of mine personnel and automatic tracking and positioning management.

Four, system function

The coal mine personnel positioning system is an integrated application system for underground personnel positioning, attendance, underground equipment maintenance, environmental monitoring, and management. It uses radio frequency identification technology and computer network communication technology to realize real-time monitoring of underground personnel, tracking and positioning, attendance management and environmental monitoring, etc., to grasp the accurate location of underground personnel in time, and provide real-time and accurate information for coal mine safety production and emergency rescue. .

1. Mine target positioning and tracking:

It can track and replay the personnel’s trajectory information in real time, query the current location of the underground personnel, set the location and time of the personnel stay within the time, and track and display it in real time.

2. Personnel paging:

Prompt the relevant personnel through the call signal sent by the monitoring substation.

3. Attendance of downhole personnel:

Through the recording and statistics of workers’ exit/entry time and staying time in the well, establish a database and print various employee information reports (down-well schedule, attendance schedule, overtime schedule, etc.).

4. Environmental monitoring and testing:

The system automatically detects the concentration of gas, CO and other toxic gases through various environmental monitoring sensor equipment.

5. Restricted area alarm:

When personnel enter the restricted area in violation of regulations, a sound and light alarm message will be issued, and the management department of the well will also record and store it in the system database at the same time.

6. Lost alarm:

The system can automatically detect and send out prompt messages when the underground is not out.

7. Emergency rescue after disaster, accident investigation provides information:

In the event of various accidents, it can immediately find out the distribution, name and specific location of underground personnel, and provide timely and accurate information to rescuers.

8. User permission settings:

The system has a user authority management function, and only authorized users can enter the system for management.

9. Query and print:

Query the current location of personnel or equipment, personnel track query, personnel distribution, query overtime personnel, attendance query and print report.

10. Unified management of certificates and identification cards:

Support operations such as adding personnel and deleting personnel files.

11. Information sharing:

Mine leaders can query and manage mine information through the Internet.

Contact: Tianjin Little Bee RFID Division

Company website: www.acbee.com

Contact number: 022-27430664

[ad_2]