RFID mine wireless data real-time acquisition and transmission system scheme

[ad_1]

Overview

The mine mineral loading and collection system is a set of barcode solutions adopted by coal mine enterprises in the production and loading links in order to increase the speed of mining and production mobile operations, manage the mining operation site in real time, and achieve the target requirements of barcode wireless data management.

This proposal was proposed by Shenzhen Jiu Rui Technology Co., Ltd. (the author).

User needs

In the process of coal mine production and mining operations, it is necessary to manage the minerals that are excavated and loaded every day with barcodes, and to scan the barcodes of the minerals loaded on each truck. Using the wireless WIFI system, the barcode of each mineral truck is transmitted to the database of the ground office in real time. And the loading status of the mining operation site can be checked at any time from the database, such as the number of vehicles loaded per day, the date of each loading, etc. At present, because there is no wireless transmission system, barcode acquisition system and related management software in the mine, the ground manager cannot know the real-time operation situation in the mine.

The following is the current situation of the customer:

A: A stable and reliable wireless transmission equipment and system are required. It can transmit the data collected by the bar code in the mine in real time. .

B: Need some bar code collection equipment, which can work stably and reliably in the mine environment. And collect barcodes.

C: Relevant software is needed to coordinate the bar code collection and wirelessly transmit it to the ground office database. The computer in the office can receive, manage, and query the data of the on-site vehicle loading in the mine at any time.

Problems that customers need to solve when applying mine wireless data acquisition and transmission systems:

In view of the above-mentioned on-site situation, it is now necessary to use wireless barcodes to solve the situation of loading vehicles in the well, and do two things:

1. Ensure that all loading data is collected in real time and uploaded to the ground office.

2, to ensure that the management software in the office can receive and manage the data sent from the underground at any time.

System function solution

According to the above user needs, the company proposes the following solutions, which are divided into system platform solutions, hardware selection solutions and software development solutions.

The system platform scheme is the overall principle architecture of the system and the theoretical basis for the other two schemes; the hardware selection scheme provides the material basis for the system to realize the system platform and meet the needs of users, and the software development scheme is a solution to user needs directly plan

These three levels of programs together constitute a solution to the requirements described in the previous section.

System platform solution

For the system solution, the user requirements can achieve the following points:

It is hoped that the management of underground mining operations can be realized through the management of bar codes.

It is hoped that the operation speed is fast and the loading situation can be managed in real time.

It can wirelessly transmit the collected bar code data in real time.

Scanning and statistical data can be inquired from the ground office.

In the mine site, each bar code collection point needs to use a wireless bar code collector.

According to the above customer needs and requirements, the following system platform architecture is recommended:

A computer is deployed in the ground office to complete the functions of receiving, storing, querying and managing collected data.

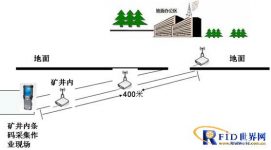

About 3 wireless APs and signal amplification antennas are deployed in the mine to form a wireless data transmission system.

Deploy a wireless barcode collection device at the mine mining and loading operation site.

The system hardware and platform of the above scheme are shown in the figure below:

Software development plan

Our company will customize and develop application software for users. The on-site business support system on the data acquisition computer should meet the needs of on-site business, various operations and provide man-machine interface design suitable for industrial on-site operations.

Complete basic on-site verification, and give necessary prompts for collection errors and missed omissions.

Development environment

This system will be based on the Microsoft .NET architecture and C# as the development language. A set of on-site collection system based on the .NET architecture will be customized on the computer side for users to realize the mineral loading collection user interface and support users in the business process. Data collection, and provide data query, storage and verification on site.

On-site collection process:

Establish the data mapping relationship of “loading collection-product” through the bar code data collection system.

The entire software data workflow is as follows:

Wireless barcode collection program——“Wireless upload——–“Webservice middleware——-? Ground office database “————- Office PC application

A total of 3 sets of software are required to complete the above program: 1. Wireless barcode collection program (terminal). 2. Webservice middleware. 3. PC-side database management application software.

1 The wireless barcode acquisition program (terminal) completes the following functions:

Collecting loading information in the well: The mining operation workers in the mine use the wireless bar code collection terminal to scan the bar code on the car after loading each car of minerals, and record the date and time of the on-site bar code collection.

Wireless real-time transmission: After each loading data is collected, you can press the send button. The data is immediately transmitted wirelessly to the computer database of the ground office.

2. Webservice middleware completes the following functions:

Facts receive bar code data and import it into the database: Realize to receive data from the mine and write it into the ground office database.

3. Office PC application

Database statistics query management: From the application program of the ground office, you can manage and query the barcode data and other related information uploaded from the well at any time.

Software function description

The on-site collection and scanning software of mineral loading in the well has the functions of bar code identification, real-time data collection and wireless upload:

1. Barcode recognition and reading

Can read all one-dimensional bar codes as required.

2. Real-time data collection

Collect data such as barcode and time and date of loading in the well and upload it wirelessly in real time.

3. Result statistics and query

The computer database of the ground office has statistics, query and real-time management of the data uploaded from the well.

Software development and implementation arrangements. The development and implementation of this software project is expected to be completed in 10 days. The specific time arrangements for each stage are as follows

Hardware selection scheme

The on-site wireless transmission equipment in the customer’s mine shall be provided by the customer according to the customer’s requirements or provided by us. Among them, the wireless equipment suitable for use in the mine environment recommended by us is as follows:

Wireless barcode acquisition equipment.

MS30 with mobile phone or MC3090R has the following advantages:

Environmental parameters:

Working temperature: Single color: -4°F to 122°F (-20°C to 50°C)

Color: 14°F to 122°F (-10°C to 50°C)

Storage temperature: -22°F to 160°F (-30°C to 70°C)

Humidity: 5% to 95% (non-condensing)

Earthquake resistance: In the operating temperature range, it can withstand the impact of multiple drops from a height of 4 feet (1.2 meters) to the concrete floor

Rolling: At room temperature, it can withstand 500 rolls of 0.5 meters (1000 drops)

Sealed environment: IP54 Category 2

Electrostatic discharge (ESD): +/-15kVDC air discharge +/-8kVDC indirect discharge +/-8kVDC direct discharge

Wireless data communication:

Wireless Local Area Network (WLAN): Symbol Spectrum 24.802.11b 802.11g

Data rate: 802.11b: 11MB per second 802.11g: 54MB per second

Frequency range: Depends on the country (region), usually 2.4 to 2.5GHz

Output power: 100Mw both in the United States and internationally

Antenna: built-in

Voice communication; integrated IP voice communication support (P2P, PBX, PTT) Wi-FiTM-certified, IEEE802.11b direct sequence expansion wireless LAN

External equipment and accessories:

Communication cradle: Single-slot USB/RS-232 rechargeable cradle for charging spare batteries

Four-slot Ethernet charging cradle Four-slot independent charging cradle

Charging: Four-slot battery charger, universal battery charging adapter

Printer: Support Symbol approved printer

Other accessories: leather case, charging cable

The main technical parameters of Symbol3090R are as follows:

Technical advantages

Since its establishment, the company has been engaged in the development and promotion of barcode application systems, especially good at developing barcode application systems in logistics, commercial department stores, and manufacturing industries. He has rich experience in development and management of Microsoft .NET architecture, Oracle, Sqlserver database, and computer information system integration.

All employees of the company are old employees from well-known IT companies (such as Huawei, IBM, etc.) or barcode companies. Provide the industry’s advanced supply chain solutions and logistics automation management ideas. Provide the best service at the best price. After adopting our company’s products, it can bring obvious management and logistics convenience, efficiency improvement and service added value to your organization. Therefore, the company has sufficient technical strength and success guarantee for the implementation of the various technological developments proposed in this plan.

Summarize

According to user needs, this program proposes feasible technical solutions from three aspects of system platform, hardware selection and software development for the user’s wireless data collection in the mine and real-time wireless upload to the ground office. The company’s technical and management advantages in the development and implementation of this program. After signing a contract with the user, the company can make a final implementation plan based on this plan and the further needs of the user, and is responsible for consulting, research and development, implementation and providing complete after-sales service.

Company address and contact information:

Please contact us as follows: Company Internet address: http://www.jiuray.com/

Address: Room 201, Building 2, Lianfa Building, No. 318, Shahe East Road, Science and Technology Park, Nanshan District, Shenzhen

Contact number: 075586597322 Contact person: Mr. Zhang Mobile: 13510831295

Fax: 075586597322

Email: [email protected]

[ad_2]