Application of RFID warehouse management in supermarkets

[ad_1]

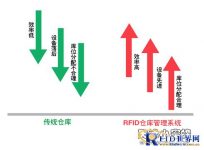

A new generation of warehouse management system represented by RFID technology is gradually replacing traditional and backward management methods. Tianjin Bee believes that compared with previous management models, RFID warehouse management is faster, more accurate, and timely, saving and liberating enterprises. A lot of manpower and management costs, especially in a warehouse environment with fast goods flow and complex product informationRFIDTechnology can better reflect its outstanding advancement and superiority.

At present, the warehouse management of domestic supermarkets still stays in the general extensive management method. Unlike foreign mechanization and automation, the current domestic use is still manual operation, which is extremely inefficient. At the same time, the equipment is backward, the management method, the distribution method of the storage location and the goods are not properly planned. At the same time, the lack of RFID technology causes the inventory information update speed to be too slow, the efficiency is extremely low, and the goods are likely to expire and cause losses.

In view of the above-mentioned problems in warehouse management, let’s briefly state the application of RFID warehouse management in supermarkets.

One warehouse space allocation

In the current warehouse management method, the division of cargo locations is generally carried out by warehouse managers based on memory and experience, which has serious drawbacks and is unreasonable. By pasting the RFID active electronic tag on the shelf, the production date, quantity and other information of the products on the shelf are injected into the label. Every time after picking up the goods from the warehouse, the out-of-stock information is transmitted to the warehouse management system through the RFID handset, and the information on the electronic tag is modified. The active tag is set to transmit frequency and transmitted to the warehouse management system through a nearby antenna , Timely inform the warehouse management staff of the quantity and expiration time of the goods in the position, so that the staff can manage the position.

Second, the inventory management of the outbound and warehousing of valuable goods

By sticking RFID electronic tags on the surface of the packaging boxes of valuable goods, all goods information can be read at one time when entering and leaving the warehouse. Compared with the previous bar code reading and writing methods, it saves a lot of time and labor costs, and the error rate is extremely high. Low. At the same time, even if the RFID technology is in the dark, the label surface can be easily read and written without being affected by contamination. At this point, it is also incomparable with traditional bar code reading and writing methods.

During the inventory, the staff only need to bring the RFID handheld to the location of the goods, quickly read the information and check the information on the inventory at one time. If the data does not match the inventory, the warehouse management system will issue an information prompt The staff conducts further checks.

Supermarket warehouse management is extremely challenging and complicated. This article attempts to solve some of the problems encountered in warehouse management from the perspective of RFID technology. Tianjin Bee believes that more RFID solutions will be applied to supermarkets in the future. In many ways, it helps the development of the enterprise.

[ad_2]