Automatic collection system of SFC flow pallet based on RFID

[ad_1]

system introduction

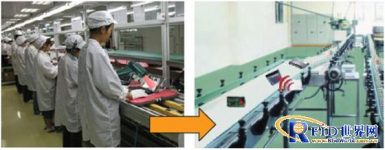

Existing SFC system data collection generally uses barcode data collection, and barcode labels are attached to products or packaging. The data collection methods are manual and automatic, and there are the following problems:

Manual: the operator holds the scanner to align the product bar code collection (disadvantages: manpower is required, there are human error factors)

Automatic: Install the automatic scanner on the pipeline (disadvantages: high rate of missed scanning, high equipment cost)

In order to solve the above problems, fixed installation of RFID in the pipeline Reader, Install or affix RFID electronic tags on the product or packing pallet, when the product passes the recognition range of the RFID reader, inductive automatic data collection is realized.

System composition

RFID reader,

TCP/IP data collector,

RFID electronic label (ISO15693 13.56MHz)

System Data Monitoring Center

system structure

Use 13.56MHz high-frequency RFID electronic tags, RFID readers, and TCP/IP data collectors to write the pallet information into the RFID electronic tags and fix them on the assembly line pallet, and install the RFID reader on the assembly line data collection station , When the pallet passes the station,RFIDThe reader automatically collects (radio frequency induction) information to the pallet and transmits it to the SFC system center through the network.

System Features

Fast data collection speed: effectively avoid collection difficulties due to bar code quality, lighting, etc.

The scan miss rate is almost zero: the floor scan rate is greatly reduced, and the product line is stopped due to missed scans.

Reduce the cost of consumables: The first investment cost of electronic tags is high, but they can be reused, and long-term evaluation can greatly reduce costs

Reduce equipment cost: The cost of automatic data collectors is high, and the use of RFID readers can save equipment costs

[ad_2]